Low-temperature-resistant air spring upper seam allowance sealing structure, method and product

A technology of air spring and sealing structure, applied in the direction of spring, spring/shock absorber, gas shock absorber, etc., can solve the problem of rubber creep that cannot be solved in the air bag, and the rubber of the body is cold and shrinked, so as to improve the sealing reliability and Use reliability, meet sealing requirements, and ensure the effect of sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

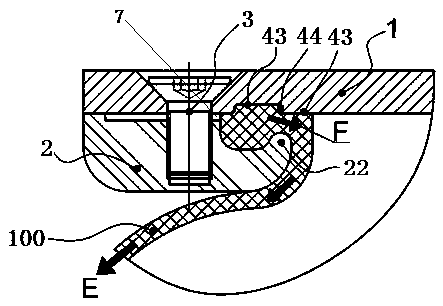

[0038] Low temperature resistant air spring upper mouth seal structure, including upper cover plate 1, buckle ring 2 close to the bottom surface of upper cover plate 1, connecting bolt 3 connecting upper cover plate 1 and buckle ring 2 and upper mouth 4 of the airbag, upper The sub-port 4 is compressed between the upper cover plate 1 and the retaining ring 2, the retaining ring 2 and the connecting bolt 3 are arranged on the radially outside of the upper sub-port 4, the capsule 100 below the upper sub-port 4 is attached to the inner wall of the retaining ring 2 Combined and attached to the bottom surface of the buckle 2 along the downward direction, it is characterized in that radial seals and axial seals are used between the upper cover plate 1 and the upper sub-port 4 and between the upper sub-mouth 4 and the buckle 2 Alternately arranged and sequentially connected sealing structures, the sealing pressure of at least one axial sealing surface of the upper sub-port 4 on the up...

Embodiment 2

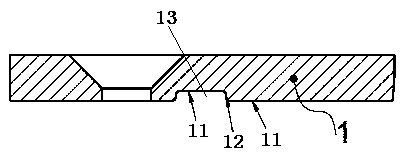

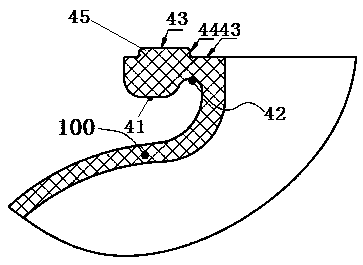

[0051] The difference from Embodiment 1 is that there is only one axial fitting surface 44 in the upper sub-mouth 4, and this axial fitting surface 44 is arranged between two radial fitting surfaces 4, where the axial fitting The height of the radial mating surface 43 inside the surface 44 is lower than the height of the radial mating surface 43 arranged outside the axial mating surface 44. The mating surface 43 is connected to form a top protrusion 45, and the axial sealing mating surface 12 is connected with the radial sealing mating surface 11 to form an upper cover plate groove 13 matched with the top protrusion 45. The top protrusion 45 There is a temperature-rising deformation gap I5 between the groove 13 of the upper cover plate. The temperature-rising deformation gap 5 is located between the outer wall of the upper sub-mouth 4 and the side wall of the upper cover plate groove 13. The upper sub-mouth 4 and the buckle ring 2 There is a heating deformation gap II6 between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com