High-pressure common rail pump high reliability and long service life single-way check valve

A high-pressure common rail and long-life technology, applied in the field of hydraulic check valves, can solve problems such as seal failure, damage to the sealing cone surface 52, compression of the return spring 92 and ring breakage, etc., to achieve stable contact seals and shorten closing time , Eliminate the effect of backflow phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

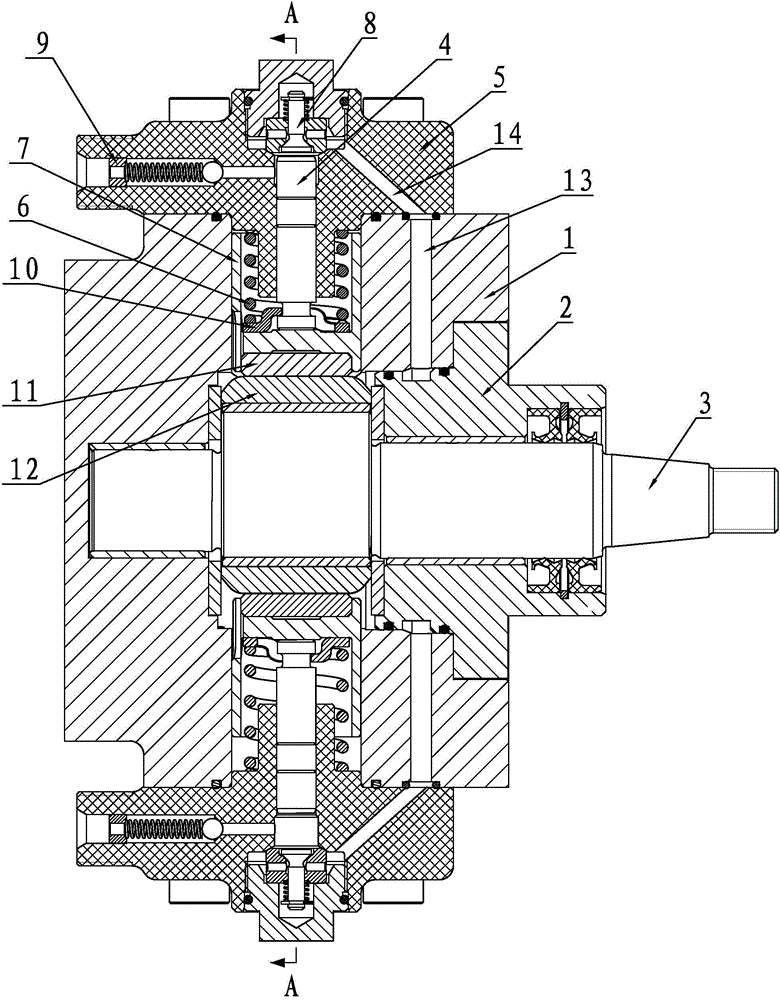

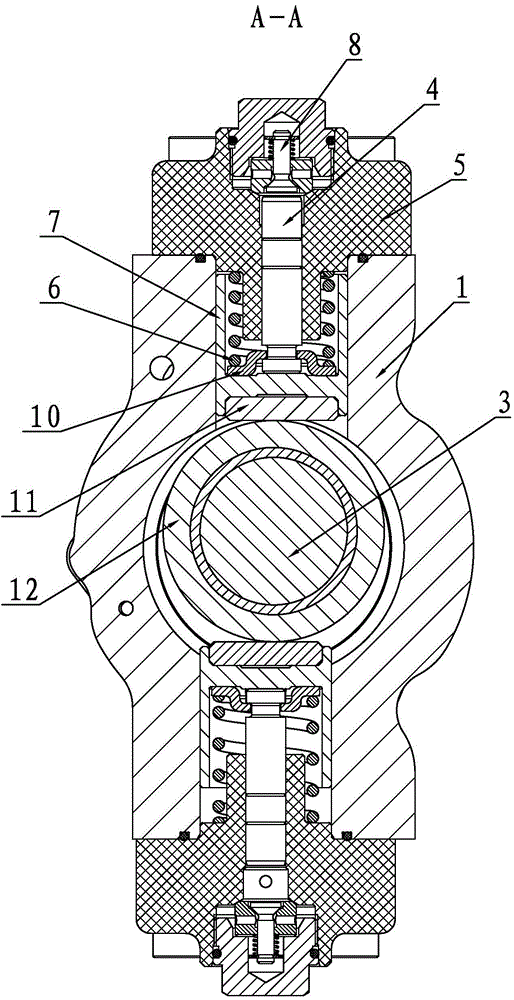

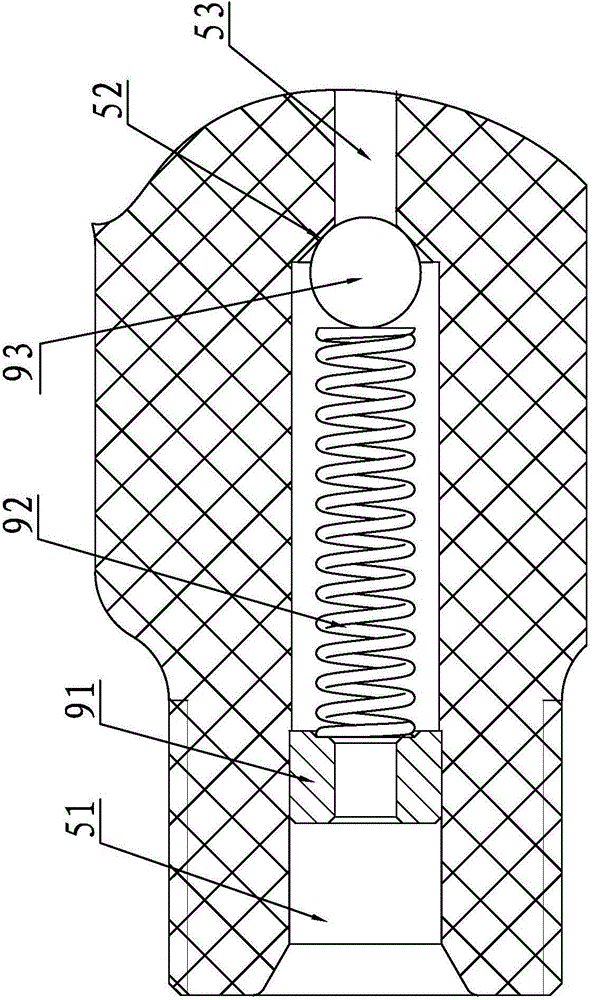

[0034] Example 1: A high-pressure common rail pump with high reliability and long life one-way check valve, such as Figure 4 ~ Figure 7 with Picture 9 As shown, including the oil outlet 51 on the plunger sleeve 5, the sealing cone 52, the oil inlet hole 53, the spring seat 91, the return spring 92, the sealing ball 93 and the sliding guide sleeve 94, on the spring seat 91 A spring seat hole 911 and a central hole 912 are provided. The shape of the sliding guide sleeve 94 is composed of two sections of column and one section of cone. The left section is the guide column 941 and the right section is the small diameter column section 942. The section 943 is arranged between the guide cylinder 941 and the small diameter cylinder section 942. The diameter of the small diameter cylinder section 942 is 3 mm smaller than that of the guide cylinder 941. A step hole is provided in the center of the sliding guide sleeve 94, and the left end is a spring. The limit hole 944 is provided wi...

Embodiment 2

[0035] Embodiment 2: The difference from Embodiment 1 lies in the structure of the sliding guide sleeve 94. In this example, such as Figure 8 As shown, the sliding guide sleeve 94 is a cylindrical sleeve with a chamfered front end, and the side oil inlet channel 947 is opened on the right end surface of the sliding guide sleeve 94 and is in communication with the spring limit hole 944.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com