Low stressed self anchoring method for group anchor steel tension cables

A steel strand, low-stress technology, applied in the direction of cable-stayed bridges, bridge parts, bridge forms, etc., can solve the problems of heavy lifting equipment, high brittleness, low safety reserve, etc., and achieve effective anchorage area increase and fatigue resistance performance Improvement, fatigue performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0034] The best implementation mode of the present invention is:

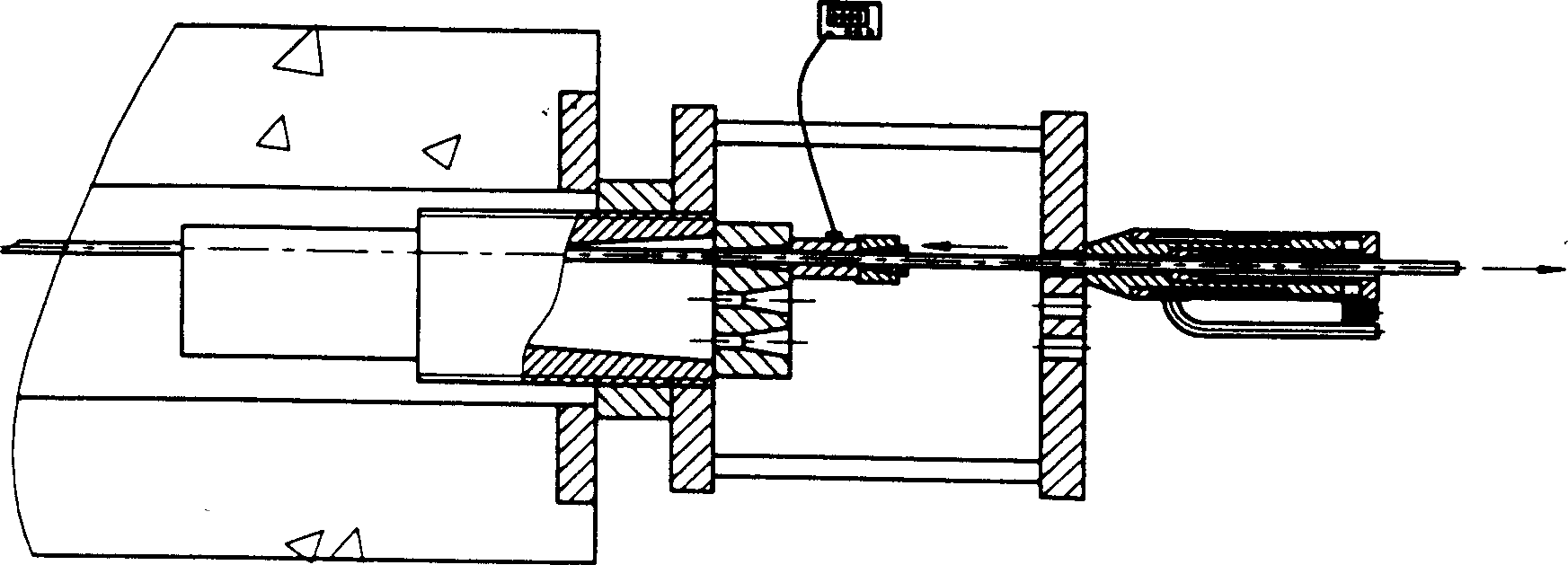

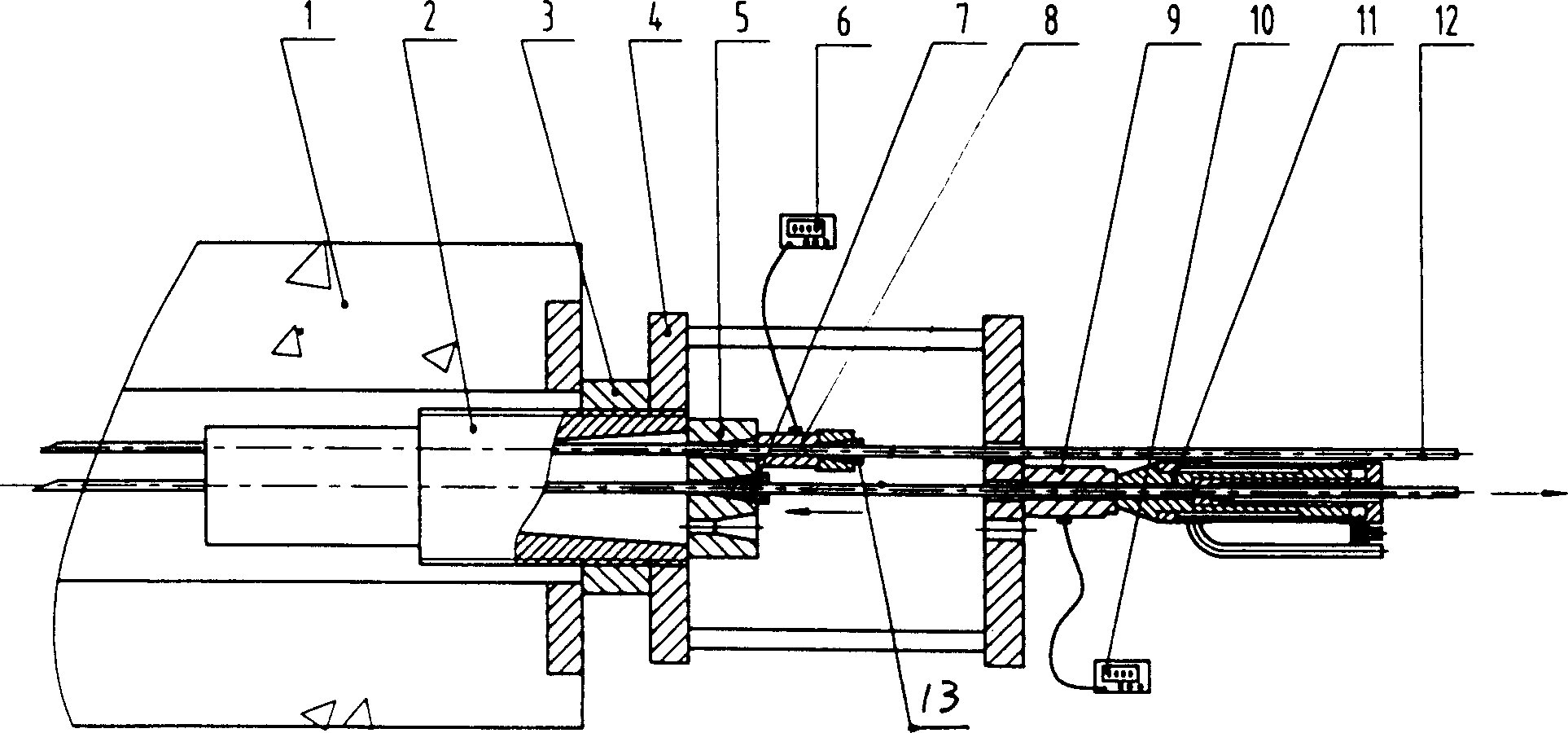

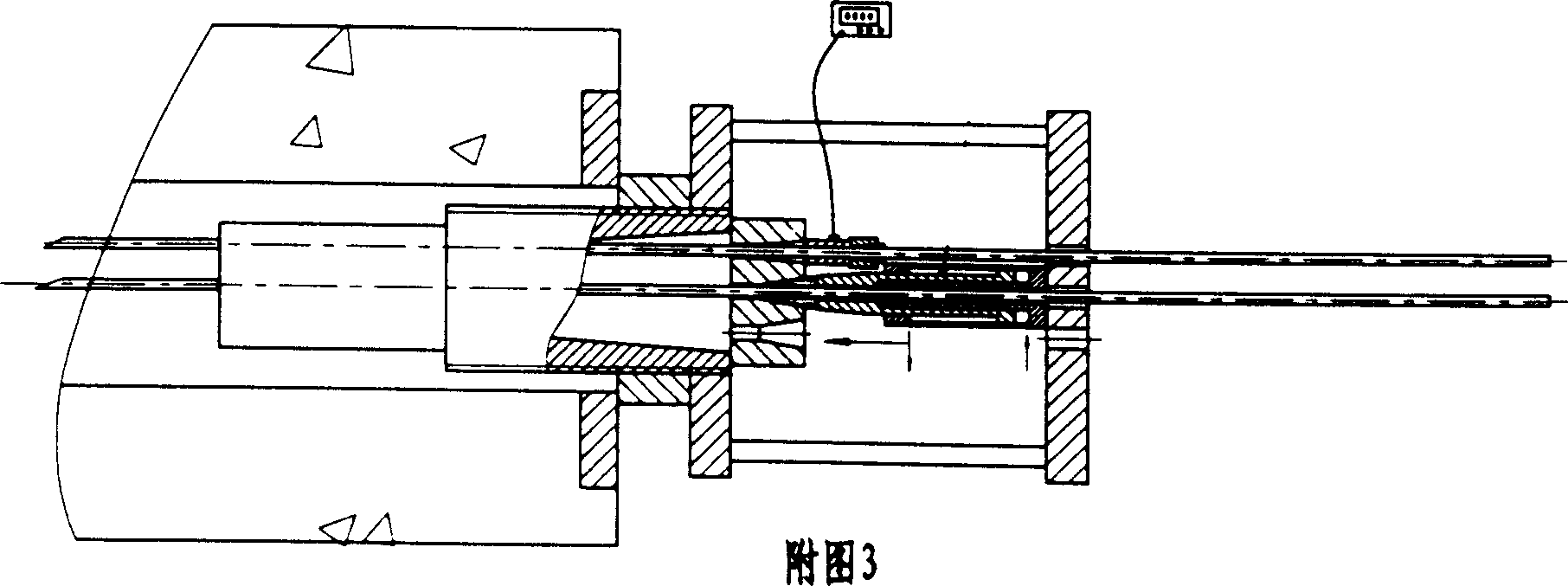

[0035] (1), install reaction force frame 4, make it be connected with supporting cylinder 2 by threaded connection; Single-hole force sensor 8 is installed on the first tensioned steel strand 12, and is connected with digital strain gauge 6, installs single Hole tool anchor assembly 13, then zero-adjust the digital strain gauge 6, use a single-hole front clip jack 13 to push against the inner side of the reaction frame 4, stretch the first steel strand 12 to the designed force value, and tighten it with a tool the tool clip in the tool anchor assembly 13;

[0036] (2), install the single-hole force sensor 9 on the second steel strand 12, and connect it with the digital strain gauge 10, and adjust zero, push the outer end surface of the reaction force frame 4 with the front clip jack 11 of the single hole Perform tensioning so that the force value displayed by the digital strain gauge 6 is consistent with the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com