Aluminum lithium alloy spectrum standard sample containing silver, and preparation method thereof

A technology for spectral standard samples and aluminum-lithium alloys, which is applied in the field of silver-containing aluminum-lithium alloy spectral standard samples and its preparation, can solve the problems of inability to prepare aluminum-lithium alloy spectral standard samples, high Ag density, etc., and avoid sinking to the bottom Phenomenon, easy to stir, and uniform ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention provides a method for preparing a silver-containing aluminum-lithium alloy spectral standard sample, comprising:

[0035] Step a) under the protection of argon, add Al, Cu, Ti and Zr into the smelting furnace, and heat to melt to obtain the first alloy melt;

[0036] Step b) taking part of the first alloy melt, adding Ag into the part of the first alloy melt, stirring to obtain a mixed solution, then adding the mixed solution into a melting furnace, and stirring to obtain a second alloy melt, The volume of the part of the first molten alloy is 0.1-1L;

[0037] Step c) adding Mg and Li to the second alloy melt to obtain a third alloy melt, and covering the third alloy melt with lithium chloride and / or lithium fluoride;

[0038] Step d) casting the third alloy melt by using a batch semi-continuous casting method under stirring conditions to obtain an ingot;

[0039] Step e) performing homogenization treatment on the ingot to obtain a silver-containing alum...

Embodiment 1

[0055] Preparation of silver-containing aluminum-lithium alloy spectroscopic standard sample E3101

[0056] Step a) Under the protection of argon, the temperature of the furnace is raised to 400°C for drying, and then high-purity aluminum is added to the smelting furnace according to the composition percentage in Table 1. After melting, Al, Cu, Ti and Zr is added in the smelting furnace and heated to melt to obtain the first alloy melt;

[0057] Step b) After adjusting its chemical composition to meet the design requirements, take 500ml of the first alloy melt with a sample spoon, add the calculated amount of Ag into the sample spoon at 820°C, stir, and place the obtained product in a melting furnace. stir;

[0058] Step c) adding Mg and Li respectively to the second alloy melt to obtain a third alloy melt, covering the third alloy melt with lithium chloride and lithium fluoride, and sampling after passing through the target slag and stirring Analysis, and then adjust its ch...

Embodiment 2~5

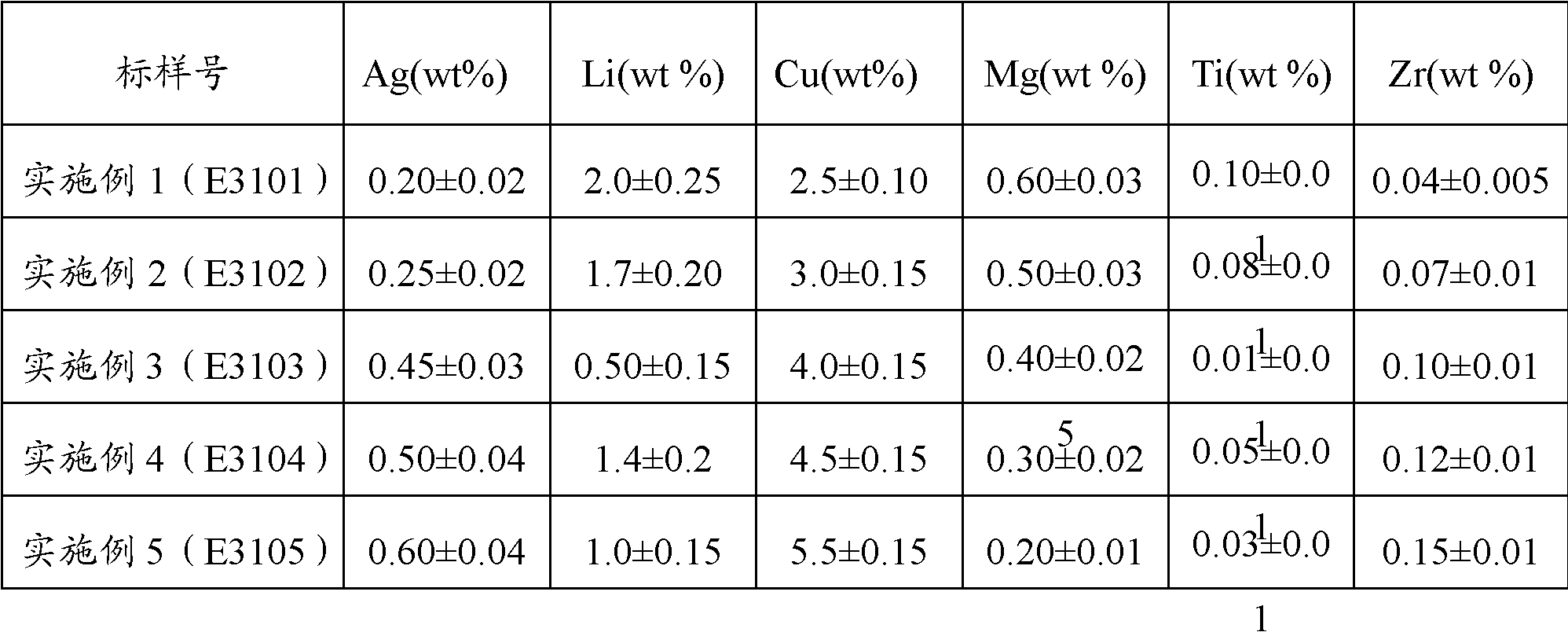

[0064] The preparation method of Examples 2-5 is the same as that of Example 1, see Table 1 for specific composition percentages, and prepare silver-containing aluminum-lithium alloy spectral standard samples E3102-E3105. .

[0065] The composition percentage of the aluminum-lithium alloy spectral standard sample containing silver in the embodiment 1~5 of table 1

[0066]

[0067] The standard samples prepared in Examples 1-5 were tested. Such as figure 1 Shown is the optical microscope image of the standard ingot E3103 prepared in Example 3. The structure of the standard ingot is dense and uniform, without defects such as pores, looseness and inclusions, and the composition is uniform.

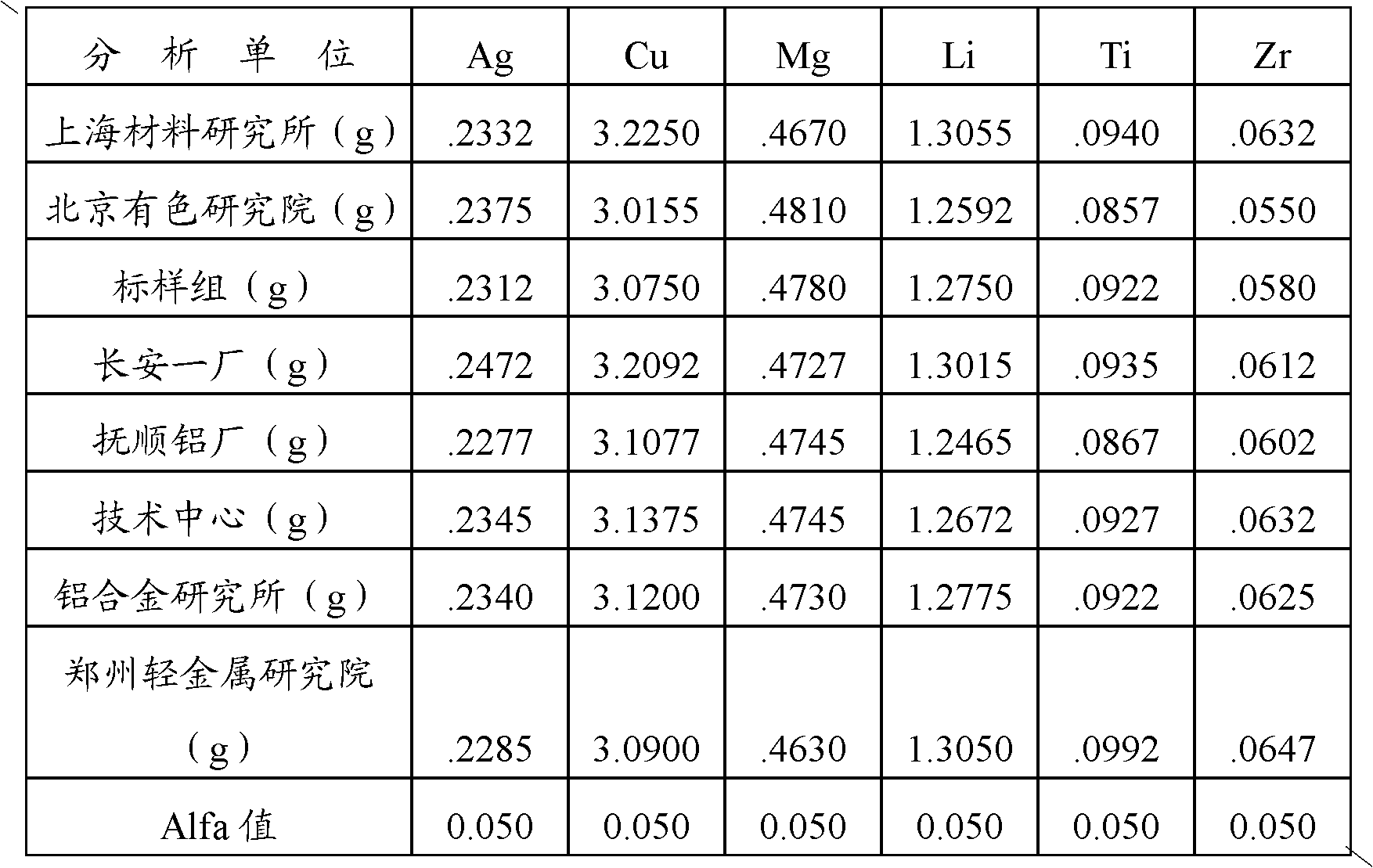

[0068] The uniformity of the standard sample is one of the most critical indicators of the standard sample. According to GB / T15000 "Standard Sample Work Guidelines" and YS / T409 "Standard Sample Technical Specifications", random sampling is tested by the range method, and the results of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com