Preparation process for improving comprehensive performance of aluminum-lithium alloy product

A technology of aluminum-lithium alloy and preparation process, which is applied in the field of aluminum alloy thermal deformation and heat treatment process, can solve the problems affecting the comprehensive performance of the alloy, and achieve the effect of improving the comprehensive performance, improving the morphology of the grain boundary, and not reducing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

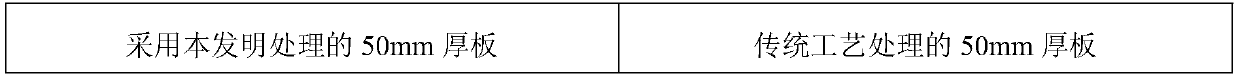

[0028] Using the process for improving the comprehensive performance of aluminum-lithium alloy products involved in the present invention, the corresponding alloy components and weight percentages are: Cu 3.89%, Li 1.73%, Mg 0.38%, Zn 0.35%, Mn 0.44%, Ag 0.35%, 0.10% Zr, 0.02% Ti, 0.06% Si, 0.11% Fe, and the balance is Al. Heat a slab with a thickness of 400mm at 380°C, then hot-roll it out of the furnace, quickly roll it to 70mm, and cool it to room temperature . Subsequently, the plate is subjected to solution quenching (495°C / 7h, water quenching at room temperature), and after quenching, the plate is placed in a heating furnace for heating at a heating temperature of 220°C, kept for 12h, and then rolled to 50mm on a rolling mill. The rolled plate is subjected to secondary solution quenching (495°C / 3h, water quenching at room temperature) + pre-stretching treatment (pre-stretching deformation 4.5% to 5.5%) + artificial aging treatment (aging process 140°C to 160°C / 15~33h) ...

Embodiment 2

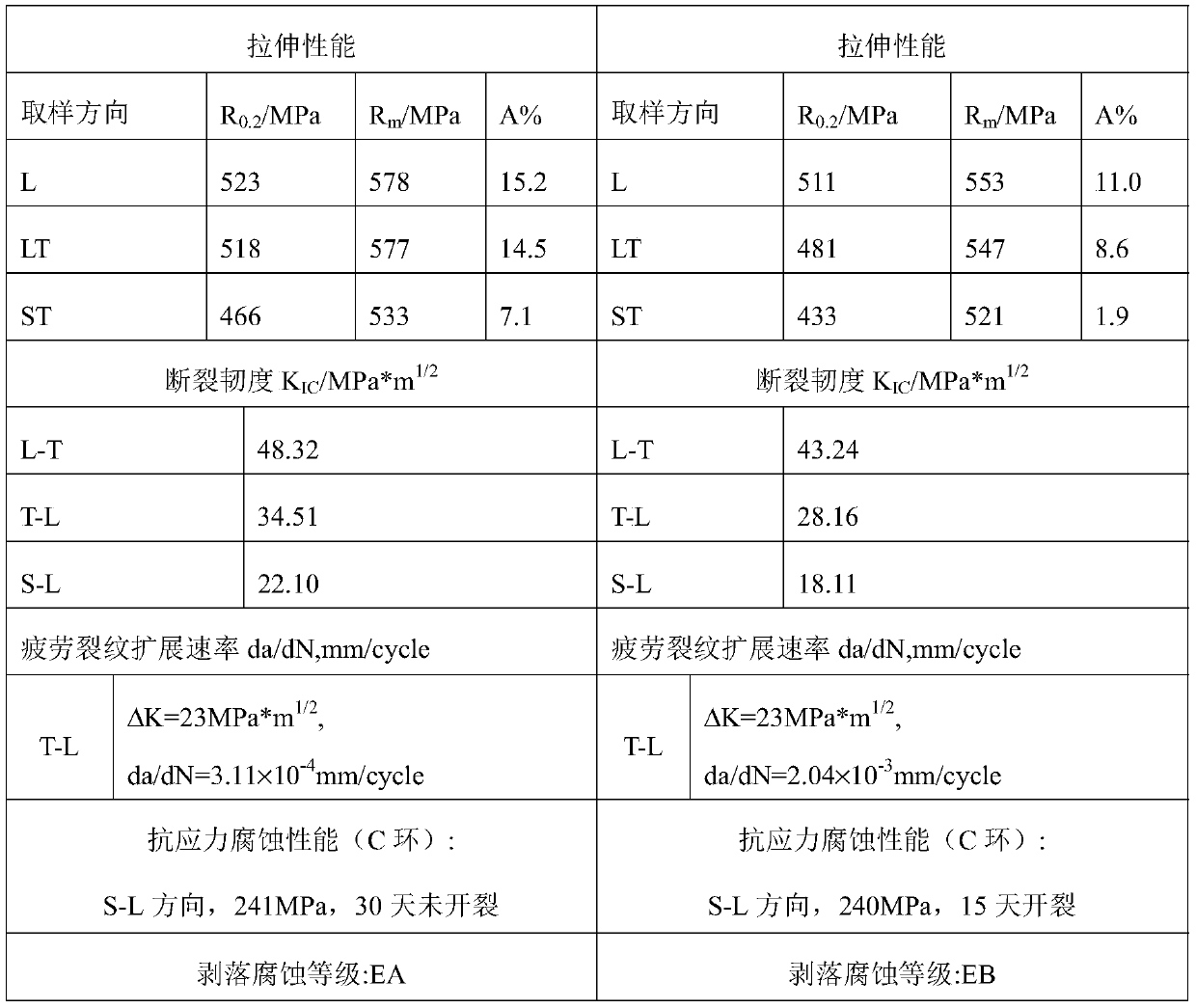

[0034] Adopting the process of improving the comprehensive performance of aluminum-lithium alloy products involved in the present invention, the alloy composition and weight percentage are: Cu4.2%, Li1.8%, Mg0.42%, Mn0.38%, Zn0.48%, Zr0.12 %, Ti 0.03%, Si0.06%, Fe 0.10%, the balance is Al, the round ingot with a diameter of 500mm after homogenization treatment is heated at 560°C, hot forged out of the furnace, and 20% is reserved for forging The amount of deformation, air cooling to room temperature, and then solution quenching (545 ℃ / 3h, water quenching at room temperature). The quenched forging is put into a heating furnace for heating at a heating temperature of 340°C and kept for 18 hours, then taken out for forging treatment, and stopped after reaching the predetermined size, and air-cooled to room temperature. Finally, carry out secondary solution treatment, solution temperature 550℃ / 1.5h, room temperature water quenching, after quenching, carry out 3.5~6.5% cold defor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com