Heat treatment method for improving damage resistance of aluminum lithium alloy thin plate

A heat treatment method and aluminum-lithium alloy technology, applied in the field of heat treatment of aluminum alloy thin plates, can solve problems such as unfavorable damage resistance and influence on the size uniformity of wide-width plates, so as to improve production efficiency and yield, good damage resistance, and improve The effect of damage resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

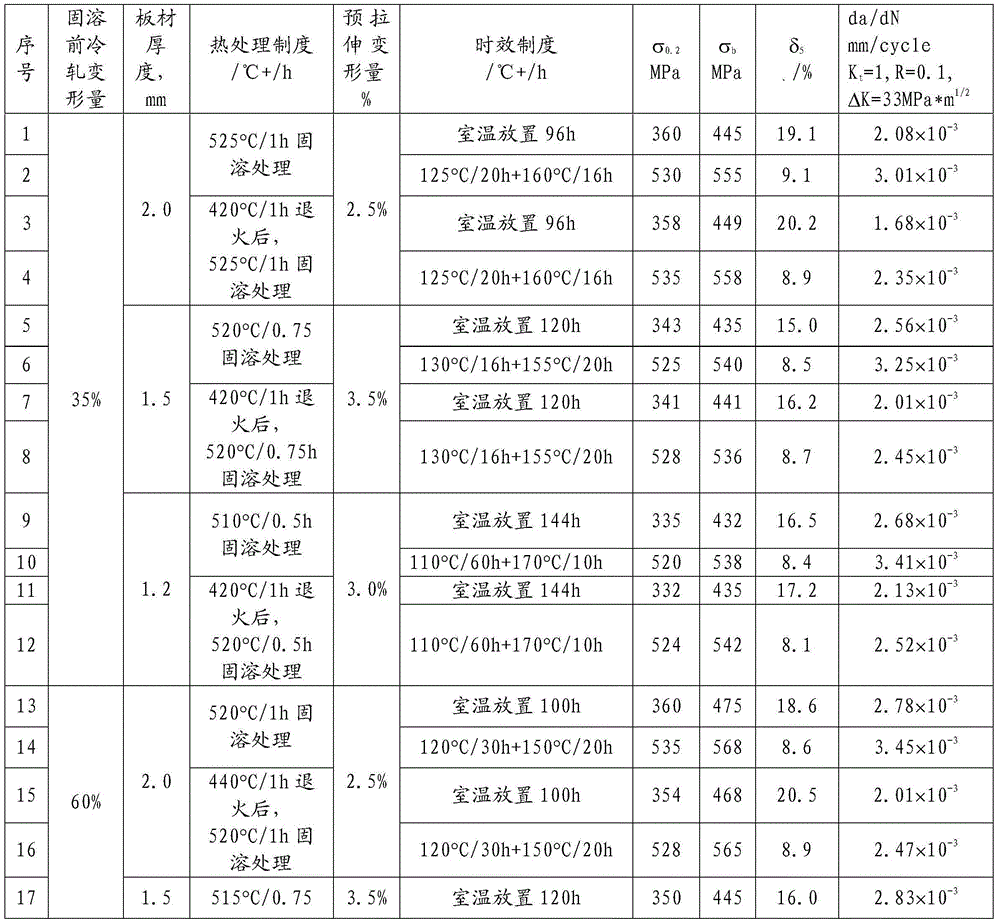

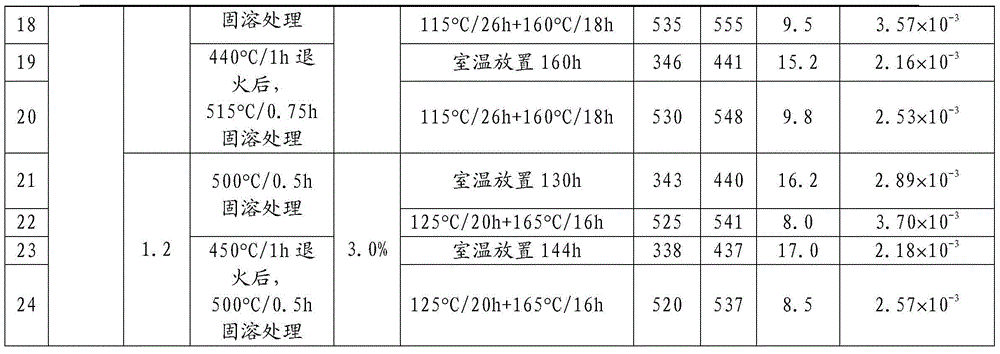

[0017] Using the Al-Cu-Li-X aluminum-lithium alloy heat treatment method involved in the present invention, the cold-rolled sheets of three specifications of 2.0, 1.5mm and 1.2mm were respectively annealed + solid solution + aging treatment, and the plates were treated to T3 State, the cold rolling deformation of the plate before solid solution is 35% and 60%, respectively, the tensile properties and da / dN properties of the plate are measured, and compared with the T3 state properties of the traditional solution process, the specific properties are shown in Table 1 shown.

[0018] Table 1 The performance corresponding to 24 embodiments of the present invention and plates of different thicknesses

[0019]

[0020]

[0021] Based on the data in Table 1, it fully demonstrates that the heat treatment method for aluminum-lithium alloy sheet proposed by the present invention can improve the damage resistance of the alloy under the premise that other properties remain unchanged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com