Multi-layer composite mold coating for aluminum-lithium alloy sand casting and coating method thereof

A multi-layer composite, sand casting technology, applied in casting molding equipment, casting molds, casting mold components, etc., to achieve the effect of improving surface quality, uniform and dense coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

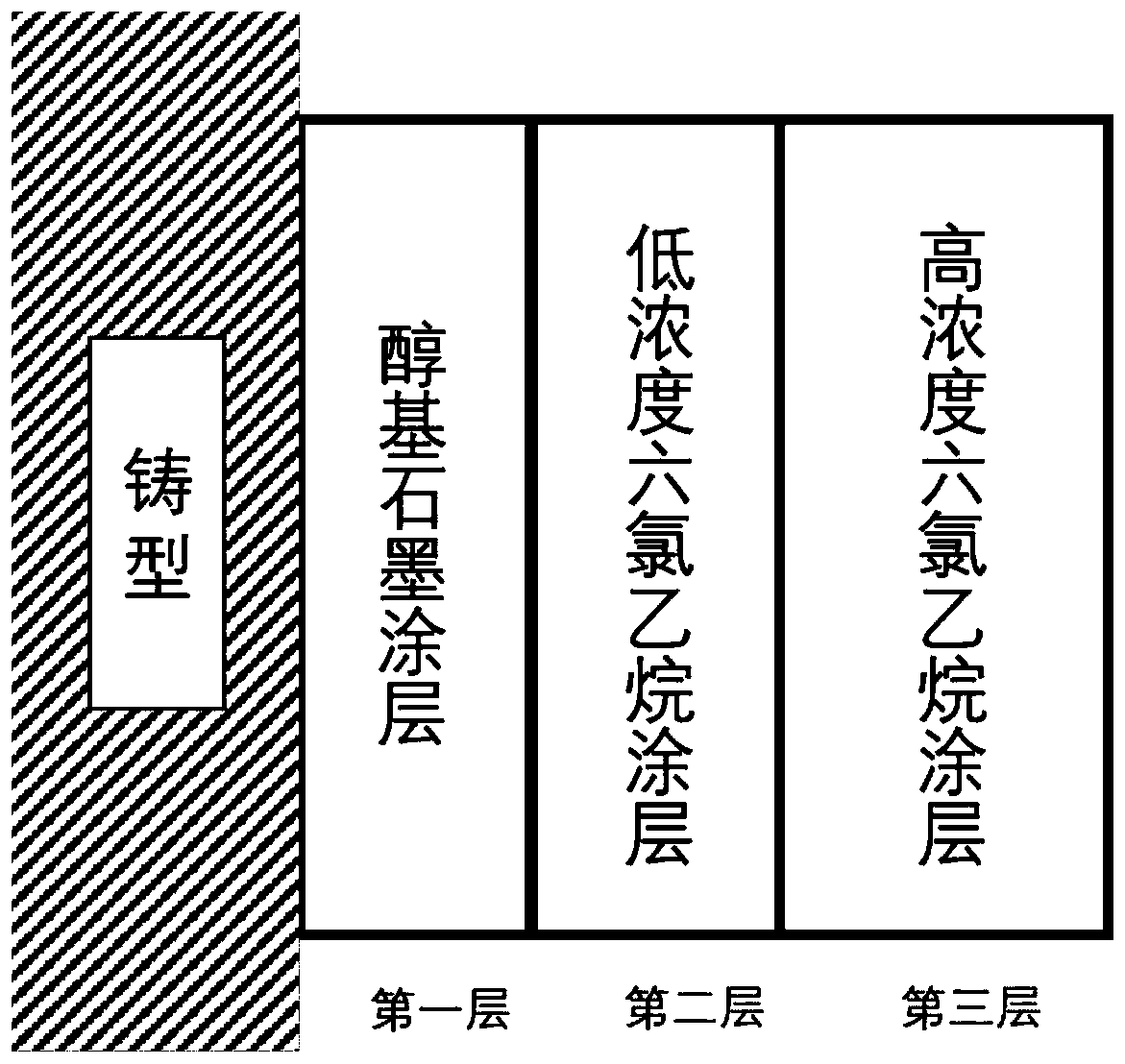

[0038] This embodiment provides a multi-layer composite coating for aluminum-lithium alloy sand casting, the multi-layer composite coating includes an alcohol-based graphite coating, a low-concentration hexachloroethane coating and a high-concentration hexachloroethane alkane coating. The coating method of the multilayer composite coating and the method for preparing aluminum-lithium alloy sand castings thereof are as follows:

[0039] (1) Weigh 1kg of alcohol-based graphite coating, stir and mix evenly.

[0040] (2) Weigh 50 g of hexachloroethane (5%), 30 g of organic bentonite (3%), 300 g of ethanol (30%), and 620 g of ether (62%). Dissolve organic bentonite in ethanol and stir for 10 minutes until it swells fully, then add hexachloroethane into ether and stir for 5 minutes to completely dissolve hexachloroethane in ether, then use manual or mechanical stirring to fully mix the two. into 1kg of low-concentration hexachloroethane paint.

[0041](3) Weigh 300 g of hexachlor...

Embodiment 2

[0049] This embodiment provides a multi-layer composite coating for aluminum-lithium alloy sand casting, the multi-layer composite coating includes an alcohol-based graphite coating, a low-concentration hexachloroethane coating and a high-concentration hexachloroethane alkane coating. The coating method of the multilayer composite coating and the method for preparing aluminum-lithium alloy sand castings thereof are as follows:

[0050] (1) Weigh 1kg of alcohol-based graphite coating, stir and mix evenly.

[0051] (2) Weigh 75g of hexachloroethane (7.5%), 35g of organic bentonite (3.5%), 325g of ethanol (32.5%), and 565g of ether (56.5%). Dissolve organic bentonite in ethanol and stir for 10 minutes until it swells fully, then add hexachloroethane into ether and stir for 5 minutes to completely dissolve hexachloroethane in ether, then use manual or mechanical stirring to fully mix the two. into 1kg of low-concentration hexachloroethane paint.

[0052] (3) Weigh 325g of hexac...

Embodiment 3

[0060] This embodiment provides a multi-layer composite coating for aluminum-lithium alloy sand casting, the multi-layer composite coating includes an alcohol-based graphite coating, a low-concentration hexachloroethane coating and a high-concentration hexachloroethane alkane coating. The coating method of the multilayer composite coating and the method for preparing aluminum-lithium alloy sand castings thereof are as follows:

[0061] (1) Weigh 1kg of alcohol-based graphite coating, stir and mix evenly.

[0062] (2) Weigh 100 g of hexachloroethane (10%), 40 g of organic bentonite (4%), 350 g of ethanol (35%), and 510 g of ether (51%). Dissolve organic bentonite in ethanol and stir for 10 minutes until it swells fully, then add hexachloroethane into ether and stir for 5 minutes to completely dissolve hexachloroethane in ether, then use manual or mechanical stirring to fully mix the two. into 1kg of low-concentration hexachloroethane paint.

[0063] (3) Weigh 350g of hexachl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com