Novel kitchen sink water faucet

A faucet and vegetable dish technology, which is applied in the field of faucets, can solve the problems of high processing cost, sand holes and cracks, and short service life, and achieve the effect of avoiding casting processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

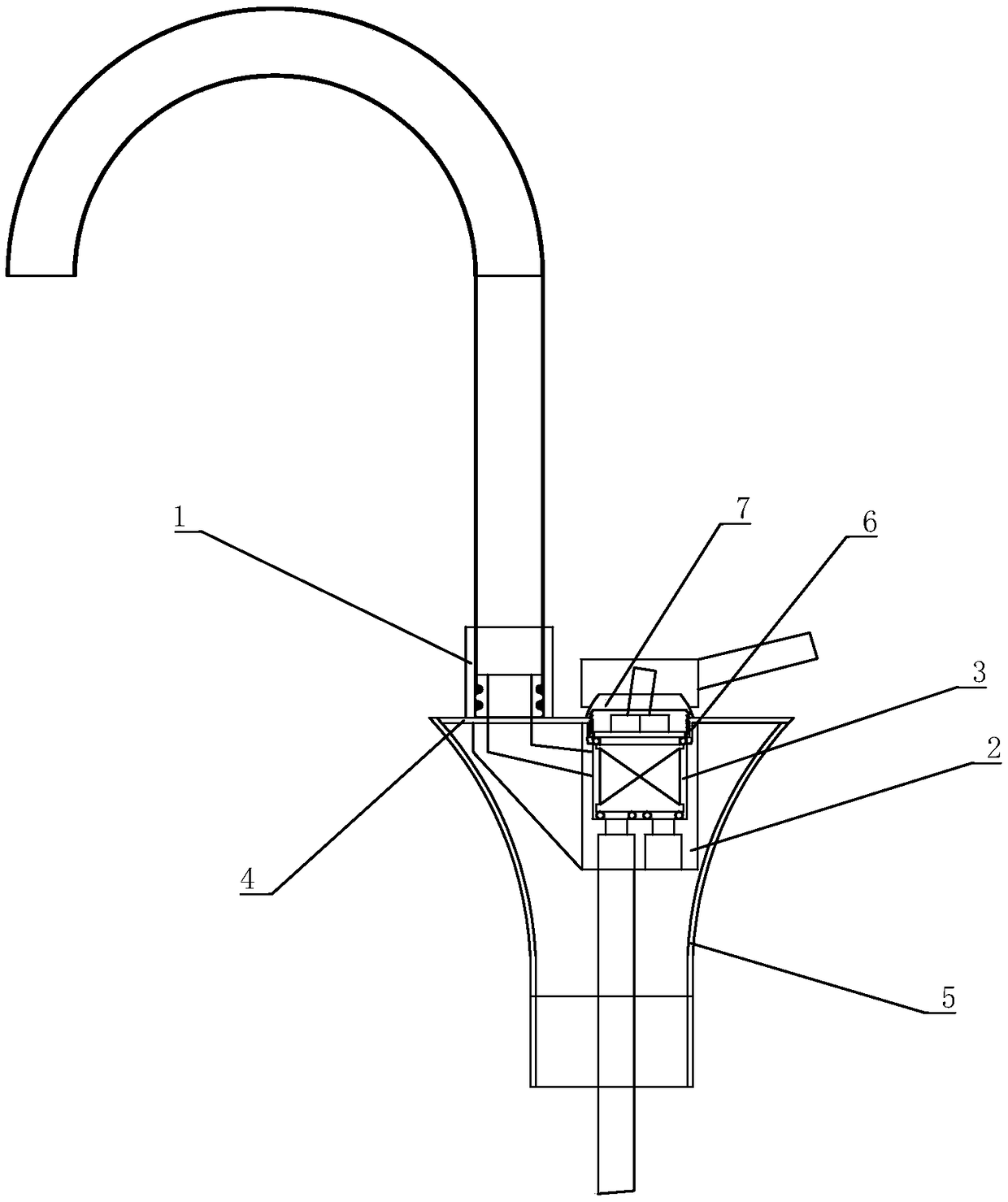

[0014] refer to figure 1 , a new type of faucet faucet of the present invention, comprising a faucet main body arranged separately, a water outlet joint 1, and a valve core seat 2, the valve core seat 2 is arranged in the main body of the faucet, and is provided with a circular installation groove 3 , the circular installation groove 3 is matched with a valve core, the main body of the faucet includes a cover plate 4 and a housing 5 connected and fixed to the cover plate 4, the cover plate 4 is provided with a through hole, and the water outlet joint 1 Fixedly connected to the top of the through hole, the valve core seat 2 is provided with a water outlet, and the water outlet is connected to the bottom of the through hole to form a waterway; the bottom surface of the cover plate 4 is provided with a mounting cylinder 6, the The circular installation groove 3 is mated with the installation cylinder 6, and the valve core stopper 7 is connected to the valve core on the installati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com