Steel piston and preparation method thereof

A steel piston and piston technology, applied in the field of steel piston and its preparation, can solve the problems of slightly poor high temperature resistance and mechanical properties, achieve good high temperature resistance and mechanical properties, avoid metallographic structure and dense metallographic structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The present application also provides a preparation method for the above-mentioned steel piston, comprising the following steps:

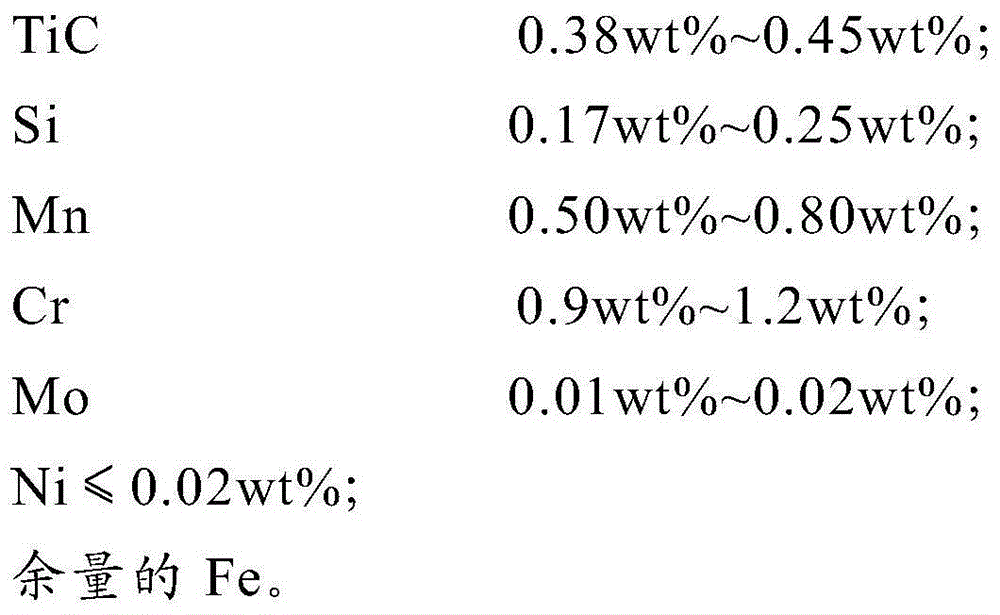

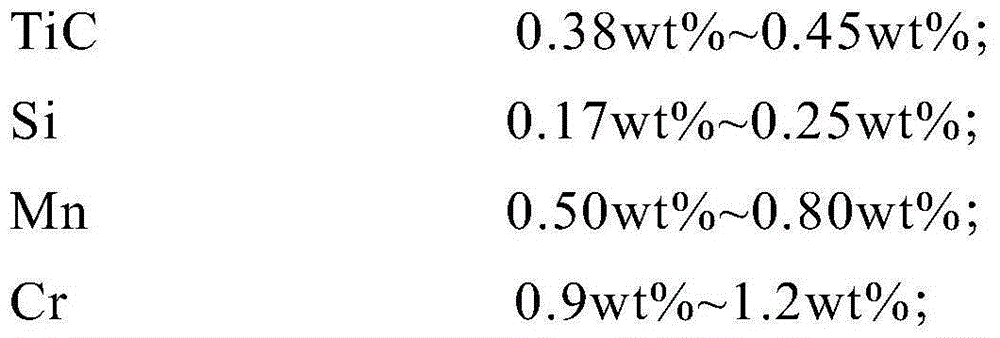

[0034] 0.38wt% to 0.45wt% of TiC, 0.17wt% to 0.25wt% of Si, 0.50wt% to 0.80wt% of Mn, 0.9wt% to 1.2wt% of Cr, 0.01wt% to 0.02wt% of Mo , ≤0.02wt% Ni is mixed with the rest of Fe and then ball milled;

[0035] Press the ball-milled material to obtain a piston blank;

[0036] Sintering the piston blank, and then quenching;

[0037] The quenched piston blank is subjected to solution treatment and then aging treatment to obtain a steel piston.

[0038] The steel piston prepared by the method of powder metallurgy in this application has the characteristics of dense metallographic structure and stable mechanical properties.

[0039] According to the present invention, the above-mentioned various components are firstly mixed, and then ball milled to obtain uniformly mixed materials. In the above process, the ball-to-material ratio of the ball m...

Embodiment 1

[0051] 0.40wt% TiC, 0.20wt% Si, 0.70wt% Mn, 1.0wt% Cr, 0.02wt% Mo, 0.01wt% Ni, other individual elements ≤ 0.05%, other elements total ≤ 0.15 % mixed with the rest of Fe, ground in a ball mill, the ball-to-material ratio is 2:1, the alcohol addition is 0.08%, and the ball milling time is 20 minutes;

[0052] After unloading, wash with tap water for 3 times, and then carry out precipitation for 25 minutes; carry out steam drying after the precipitation, and then carry out glue mixing after grasping the clear water in the hand, the ratio is 0.08%, and then carry out vibration drying, the time is 25 minutes;

[0053] Put the mixed and ground material into the mold and press it into a piston blank;

[0054] Put the piston blank in a vacuum sintering furnace, heat it up to 1400°C at a rate of 5°C / min and sinter for 3.5 hours, then cool it down to 860°C at a rate of 5°C / min and keep it for 3 hours, then put it out of the furnace and put it in an oil tank for quenching;

[0055] Co...

Embodiment 2

[0058] 0.38wt% TiC, 0.17wt% Si, 0.50wt% Mn, 0.9wt% Cr, 0.01wt% Mo, 0.02wt% Ni, other individual elements ≤ 0.05%, other elements total ≤ 0.15 % mixed with the rest of Fe, ground in a ball mill, the ball-to-material ratio is 2:1, the alcohol addition is 0.05%, and the ball milling time is 20 minutes;

[0059] After unloading, wash with tap water for 3 times, and then carry out precipitation for 25 minutes; carry out steam drying after the precipitation, hold it in your hand and do not squeeze clear water, then carry out glue mixing, the ratio is 0.05%, and then carry out vibration drying, the time is 25 minutes;

[0060] Put the mixed and ground material into the mold and press it into a piston blank;

[0061] Put the piston blank in a vacuum sintering furnace, heat up to 1300°C at a rate of 3°C / min and sinter for 3.5 hours, then cool down to 830°C at a rate of 8°C / min and keep it for 3 hours, then put it out of the furnace and put it in an oil tank for quenching;

[0062] Co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

| Yield point | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com