Al (aluminum) and Li (lithium) alloy material and extrusion method thereof

An aluminum-lithium alloy, extrusion method technology, applied in metal processing equipment and other directions, can solve the problems of original grain boundary residue, unsuitable for manufacturing large-thickness materials above 40mm, low vehicle high-direction elongation, etc. The effect of elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

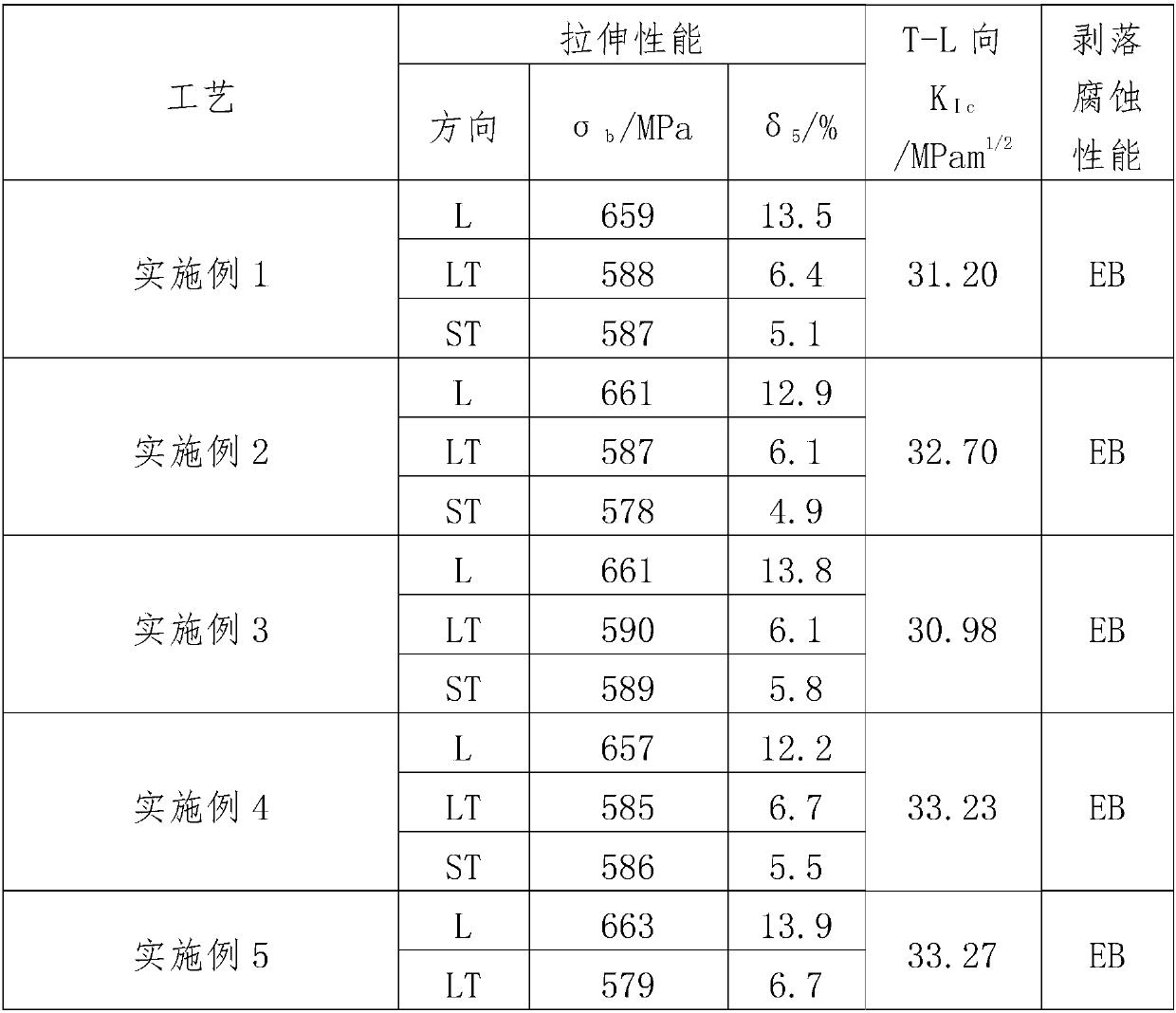

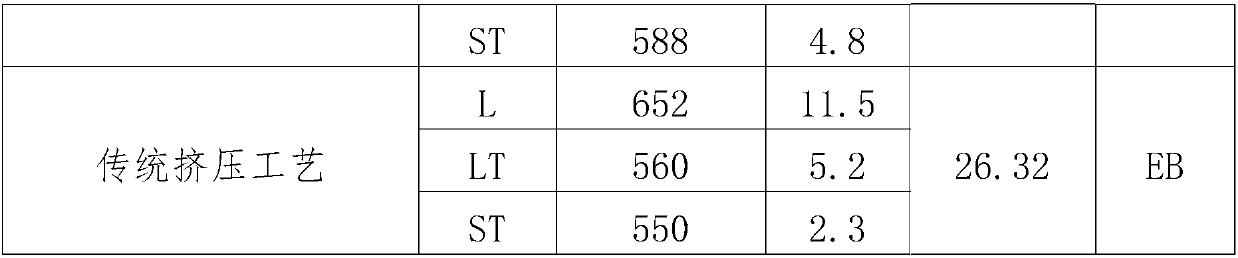

Examples

Embodiment 1

[0023] The alloy composition contains: 4.0% Cu, 0.8% Mg, 1.2% Li, 0.4% Ag, 0.10% Zr, 0.4% Mn, 0.4% Zn, Si≤0.08%, Fe≤0.10%, other impurities individually ≤0.05%, total Amount ≤ 0.15%, the balance is Al.

[0024] Homogenization treatment: heat the blank to 420°C, holding time for 6h; continue to heat up to 480°C, holding time for 38 hours; cool to 200°C with the furnace, and air cool to room temperature;

[0025] Ingot forging billet opening, initial forging temperature 380°C, final forging temperature 350°C, forging ratio 3;

[0026] Low temperature forging: initial forging temperature 340℃, forging ratio 2.5;

[0027] Extrusion, extrusion blank temperature 400 ℃, extrusion ratio 6.

Embodiment 2

[0029] Alloy composition contains: 4.0% Cu, 0.4% Mg, 1.2% Li, 0.4% Ag, 0.10% Zr, 0.4% Mn, Si≤0.08%, Fe≤0.10%, other impurities individually ≤0.05%, total ≤0.15% , the balance being Al.

[0030] Homogenization treatment: heat the blank to 420°C, hold for 2 hours; continue to heat up to 490°C, hold for 38 hours; cool to 200°C with the furnace, and air cool to room temperature;

[0031] Ingot forging billet opening, the initial forging temperature is 400°C, the final forging temperature is 360°C, and the forging ratio is 3.5;

[0032] Low temperature forging: initial forging temperature 300℃, forging ratio 3.3;

[0033] Extrusion, extrusion blank temperature 380 ℃, extrusion ratio 6.

Embodiment 3

[0035] Alloy composition contains: 3.2% Cu, 1.2% Mg, 1.0% Li, 0.4% Ag, 0.10% Zr, 0.4% Mn, Si≤0.08%, Fe≤0.10%, other impurities individually ≤0.05%, total ≤0.15% , the balance being Al.

[0036] Homogenization treatment: heat the blank to 420°C, hold for 8 hours; continue to heat up to 500°C, hold for 38 hours; cool to 200°C with the furnace, and air cool to room temperature;

[0037] Ingot forging billet opening, the initial forging temperature is 420°C, the final forging temperature is 350°C, and the forging ratio is 4;

[0038] Low temperature forging: initial forging temperature 260℃, forging ratio 2.5;

[0039] Extrusion, extrusion blank temperature 390 ℃, extrusion ratio 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com