Aluminum-lithium alloy and forging method

A technology of aluminum-lithium alloy and alloy composition, which is applied in the field of metal material engineering, can solve the problems of residual original grain boundaries, unsuitability for manufacturing large and thick parts with a thickness of more than 40mm, and low elongation in the high direction, so as to improve the elongation in the high direction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

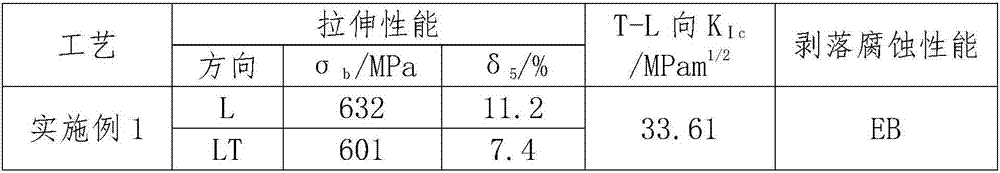

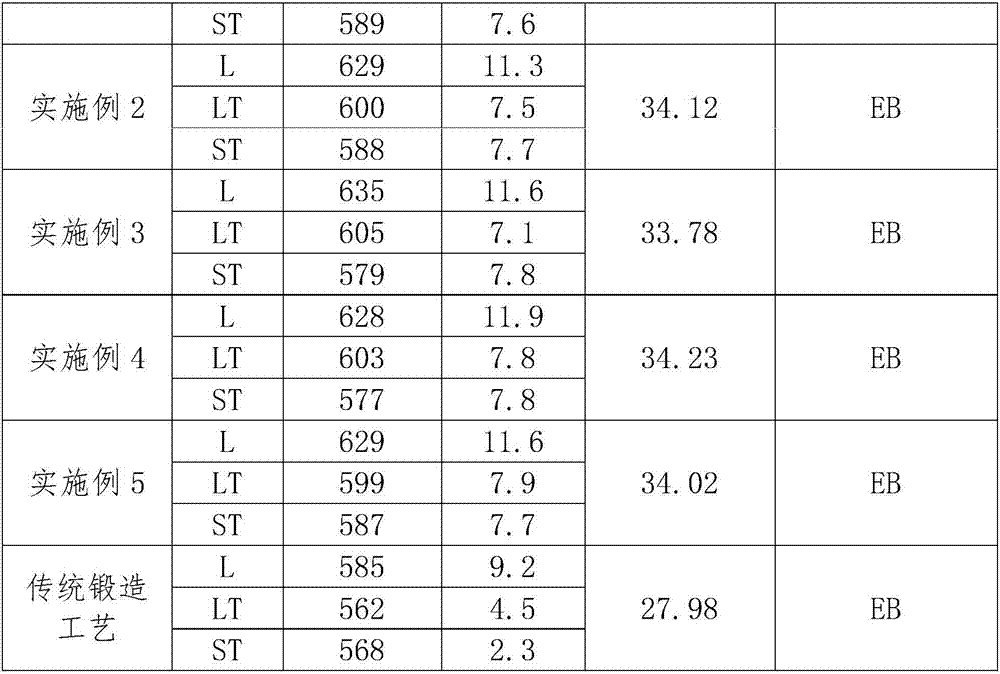

Examples

Embodiment 1

[0020] Alloy composition: 4.0%Cu, 0.8%Mg, 1.2%Li, 0.4%Ag, 0.10%Zr, 0.4%Mn, 0.4%Zn, Si≤0.08%, Fe≤0.10%, other impurities individually≤0.05%, total ≤0.15%, the balance is Al.

[0021] Homogenization treatment: heat the blank to 420°C, holding time for 2h; continue to heat up to 480°C, holding time for 38 hours; cool down to 200°C with the furnace, and air-cool to room temperature;

[0022] Ingot forging and blanking: the initial forging temperature is 380 °C, the final forging temperature is 350 °C, and the forging ratio is 3;

[0023] Low temperature forging: the initial forging temperature is 340℃, and the forging ratio is 2.6;

[0024] High temperature forging: the initial forging temperature is 400 °C, the final forging temperature is 380 °C, and the forging ratio is 4.

Embodiment 2

[0026] Alloy composition: 4.0%Cu, 0.4%Mg, 1.2%Li, 0.4%Ag, 0.10%Zr, 0.4%Mn, Si≤0.08%, Fe≤0.10%, other impurities individually≤0.05%, total amount≤0.15%, The remainder is Al.

[0027] Homogenization treatment: heat the blank to 420°C, holding time for 6h; continue to heat up to 490°C, holding time for 40 hours; cool to 200°C with the furnace, and air-cool to room temperature;

[0028] Ingot forging and blanking: the initial forging temperature is 400 °C, the final forging temperature is 300 °C, and the forging ratio is 3.3;

[0029] Low temperature forging: the initial forging temperature is 340℃, and the forging ratio is 2.6;

[0030] High temperature forging: the initial forging temperature is 410 °C, the final forging temperature is 380 °C, and the forging ratio is 4.2.

Embodiment 3

[0032] Alloy composition: 3.2%Cu, 1.2%Mg, 1.0%Li, 0.4%Ag, 0.10%Zr, 0.4%Mn, Si≤0.08%, Fe≤0.10%, other impurities individually≤0.05%, total amount≤0.15%, The remainder is Al.

[0033] Homogenization treatment: heat the blank to 430°C, holding time for 8h; continue to heat up to 500°C, holding time for 45 hours; cool to 200°C with the furnace, and air-cool to room temperature;

[0034] Ingot forging and blanking: the initial forging temperature is 420 °C, the final forging temperature is 350 °C, and the forging ratio is 4;

[0035] Low temperature forging: the initial forging temperature is 260℃, and the forging ratio is 2.7;

[0036] High temperature forging: the initial forging temperature is 420 °C, the final forging temperature is 380 °C, and the forging ratio is 4.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com