Extrusion deformation aluminum-lithium alloy with high Zn content and high strength and toughness, and preparation method thereof

A technology of extrusion deformation and aluminum-lithium alloy, which is applied in the field of metal materials and metallurgy, can solve problems such as deterioration of alloy plasticity, and achieve the effect of improving corrosion resistance, good corrosion resistance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

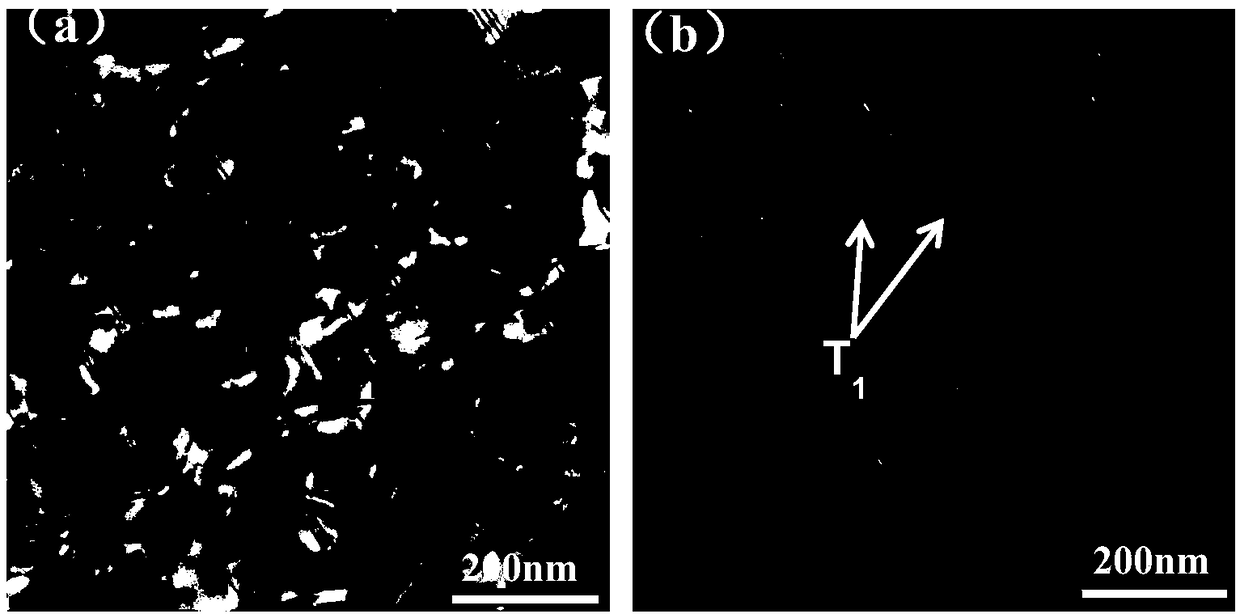

Image

Examples

Embodiment 1

[0041] Preheat the Al-Cu master alloy, Al-Zr master alloy, pure lithium, pure zinc, pure magnesium and pure aluminum to 180°C-200°C. Pure aluminum is then melted in a graphite crucible. After the pure aluminum is melted, Al-Cu master alloy, Al-Zr master alloy, pure magnesium and pure zinc are sequentially added in the temperature range of 740°C-780°C. Sprinkle a covering agent on the surface of the molten metal, add pure lithium under the protection of argon, and then remove slag and refine. Then stir evenly, remove the slag and sprinkle it into the covering agent. When the temperature of the melt drops to about 730°C, add C 2 Cl 6 The refining agent refines the melt and removes slag. After standing still for 4 minutes, under the protection of argon, the melt was continuously cast to obtain an ingot. The homogenization process of the ingot is: heat preservation at 460°C for 12h, then heat preservation at 510-520°C for 10h, and finally heat preservation at 540-550°C for 2h ...

Embodiment 2

[0048] Preheat the Al-Cu master alloy, Al-Zr master alloy, pure lithium, pure zinc, pure magnesium and pure aluminum to 180°C-200°C. Pure aluminum is then melted in a graphite crucible. After the pure aluminum is melted, Al-Cu master alloy, Al-Zr master alloy, pure magnesium and pure zinc are sequentially added in the temperature range of 740°C-780°C. Sprinkle a covering agent on the surface of the molten metal, add pure lithium under the protection of argon, and then remove slag and refine. Then stir evenly, remove the slag and sprinkle it into the covering agent. When the temperature of the melt drops to about 730°C, add C 2 Cl 6 The refining agent refines the melt and removes slag. After standing still for 4 minutes, under the protection of argon, the melt was continuously cast to obtain an ingot. The homogenization process of the ingot is: heat preservation at 460°C for 12h, then heat preservation at 510-520°C for 10h, and finally heat preservation at 540-550°C for 2h....

Embodiment 3

[0055] Preheat the Al-Cu master alloy, Al-Zr master alloy, pure lithium, pure zinc, pure magnesium and pure aluminum to 180°C-200°C. Pure aluminum is then melted in a graphite crucible. After the pure aluminum is melted, Al-Cu master alloy, Al-Zr master alloy, pure magnesium and pure zinc are sequentially added in the temperature range of 740°C-780°C. Sprinkle a covering agent on the surface of the molten metal, add pure lithium under the protection of argon, and then remove slag and refine. Then stir evenly, remove the slag and sprinkle it into the covering agent. When the temperature of the melt drops to about 730°C, add C 2 Cl 6 The refining agent refines the melt and removes slag. After standing still for 4 minutes, under the protection of argon, the melt was continuously cast to obtain an ingot. The homogenization process of the ingot is: heat preservation at 460°C for 12h, then heat preservation at 510-520°C for 10h, and finally heat preservation at 540-550°C for 2h....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com