Lithium metaaluminate coated aluminum lithium alloy composite material and preparation method of lithium sulphur battery

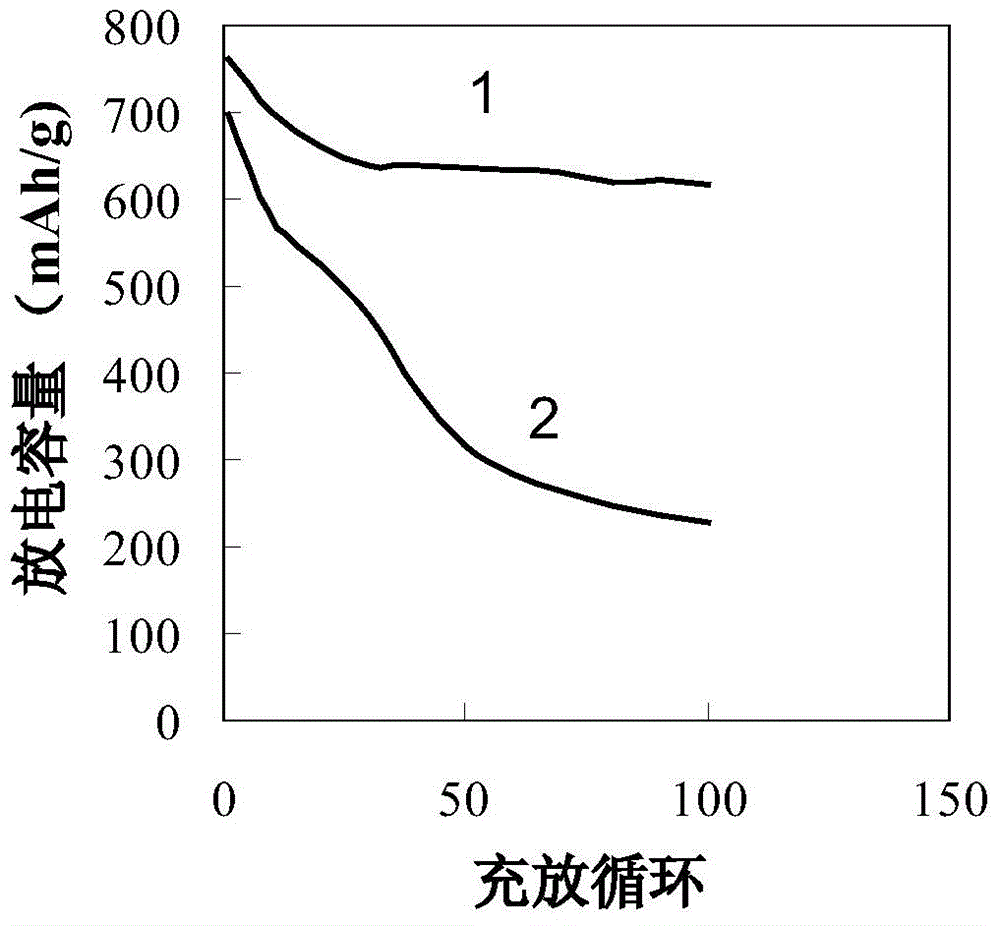

A technology of lithium metaaluminate and composite materials, which is applied in lithium batteries, electrode manufacturing, battery electrodes, etc., can solve the problems of poor cycle performance of lithium-ion batteries, cracks and pulverization of alloys, and loss of reversible lithium storage. Achieve good chemical stability and thermal stability, stable charge and discharge voltage platform, and be conducive to the effect of electrode processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The preparation method of lithium metaaluminate-coated aluminum-lithium alloy composite material specifically comprises the following steps: in an argon-protected glove box, after mechanically mixing spherical aluminum powder and lithium source compound powder, sealing them in a 316 stainless steel Then remove the reactor from the glove box, heat the reactor to 350-600°C, react in vacuum for 1-2 hours, then cool to 10-30°C to obtain aluminum-lithium alloy composite powder coated with lithium metaaluminate;

[0031] Among them, in the spherical aluminum powder and the lithium source compound powder, the molar ratio of aluminum element to lithium element is 1:1, and the purity of the spherical aluminum powder is 99.99%, and the particle size is 1-20 microns; the lithium source compound is oxidized Lithium or lithium compounds (lithium hydroxide, lithium carbonate) that can be decomposed by heating to obtain lithium oxide. If the diameter of the spherical aluminum powder i...

Embodiment 1

[0039] Example 1 Lithium oxide is used as raw material to prepare lithium metaaluminate-coated aluminum-lithium alloy composite material

[0040] In an argon protective glove box, spherical aluminum powder (1 mole of aluminum: 27g) with a purity of 99.99% and a particle size of 1-10 microns and lithium oxide (Li 2 O) Powder (0.5 mole of lithium oxide: 15g, containing 1 mole of lithium element) is mechanically mixed evenly and sealed in a 316 stainless steel reactor; remove the reactor from the glove box, heat the reactor to 350°C, react in vacuum for 1 hour and then cool to 10° C. to obtain a lithium metaaluminate-coated aluminum-lithium alloy composite material.

Embodiment 2

[0041] Example 2 Lithium hydroxide is used as raw material to prepare lithium metaaluminate-coated aluminum-lithium alloy composite material

[0042] In an argon protective glove box, mechanically mix spherical aluminum powder (1 mole of aluminum: 27g) and lithium hydroxide powder (1 mole of lithium hydroxide: 24g) with a purity of 99.99% and a particle size of 5 to 15 microns Sealed in a 316 stainless steel reactor; remove the reactor from the glove box, heat the reactor to 540°C, react in vacuum for 1.5 hours and then cool to 20°C to obtain a lithium metaaluminate-coated aluminum-lithium alloy composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com