High-strength high-toughness aluminum lithium alloy and preparation method thereof

A high-toughness aluminum and lithium alloy technology, applied in the field of aluminum alloys, can solve the problems of low purity of alloy melt, reduce alloy plasticity, and unfavorable alloy plasticity, and achieve the effects of eliminating casting defects, improving plasticity and toughness, and reducing casting defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

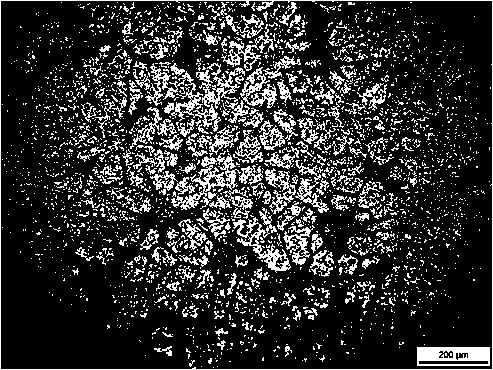

Image

Examples

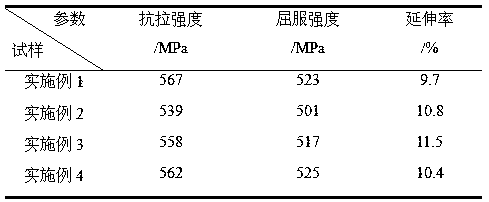

Embodiment 1

[0033] A high-strength and high-toughness aluminum-lithium alloy, composed of the following components in mass percentage: Li: 2.1%, Cu: 3.8%, Mg: 0.2%, Co: 0.25%, Sr: 0.1%, Y: 0.12%, Zr: 0.09%, and the balance is Al; the mass ratio of Cu / Li is 1.8.

[0034] The preparation method of the above-mentioned high-strength and high-toughness aluminum-lithium alloy comprises the following steps:

[0035] (1) Dosing according to the mass percentage of each component in the alloy; preheat the prepared raw materials, and put them into the vacuum induction melting furnace, vacuumize until the vacuum degree reaches 1 Pa, and then introduce high-purity argon to the furnace pressure Reach 300 Pa, heat up to 850°C for melting, and obtain molten metal;

[0036] (2) The molten metal obtained in step (1) was refined in argon at 720°C for 12 minutes, and mechanical stirring was maintained during the argon refining; after standing at 730°C for 10 minutes, it was cast into a plate with a cross-se...

Embodiment 2

[0044] A high-strength and high-toughness aluminum-lithium alloy, composed of the following components in mass percentage: Li: 1.8%, Cu: 2.9%, Mg: 0.3%, Co: 0.20%, Sr: 0.18%, Y: 0.11%, Zr: 0.06%, the balance is Al; the mass ratio of Cu / Li is 1.6.

[0045] The preparation method of the above-mentioned high-strength and high-toughness aluminum-lithium alloy comprises the following steps:

[0046] (1) Dosing according to the mass percentage of each component in the alloy; preheat the prepared raw materials, and put them into the vacuum induction melting furnace, vacuumize until the vacuum degree reaches 0.1 Pa, and then introduce high-purity argon to the furnace pressure Reach 350 Pa, heat up to 820°C for melting to obtain molten metal;

[0047] (2) The molten metal obtained in step (1) was refined in argon at 710°C for 10 minutes, and mechanical stirring was maintained during the argon refining; after standing at 720°C for 8 minutes, it was cast into a plate with a cross-sectio...

Embodiment 3

[0054] A high-strength and high-toughness aluminum-lithium alloy, composed of the following components in mass percentage: Li: 1.6%, Cu: 3.2%, Mg: 0.5%, Co: 0.25%, Sr: 0.15%, Y: 0.12%, Zr: 0.10%, the balance is Al; wherein the mass ratio of Cu / Li is 2.0.

[0055] The preparation method of the above-mentioned high-strength and high-toughness aluminum-lithium alloy comprises the following steps:

[0056] (1) Dosing according to the mass percentage of each component in the alloy; preheat the prepared raw materials, and put them into the vacuum induction melting furnace, vacuumize until the vacuum degree reaches 10 Pa, and then introduce high-purity argon to the furnace pressure Reach 250 Pa, heat up to 830°C for melting, and obtain molten metal;

[0057] (2) Refining the molten metal obtained in step (1) at 730°C for 15 minutes with argon gas, maintaining mechanical agitation during argon refining; then standing at 720°C for 10 minutes, and casting it into a plate with a cross-s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com