Aluminum-lithium alloys, and methods for producing the same

a technology of aluminum alloys and alloy strips, which is applied in the direction of manufacturing tools, metal-working apparatus, shaping tools, etc., can solve the problems of difficult to increase the strength of aluminum alloys without decreasing the toughness of aluminum alloys, and achieve the effect of avoiding non-uniformity problems, reducing the change of aluminum alloys during casting, and improving the properties of strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

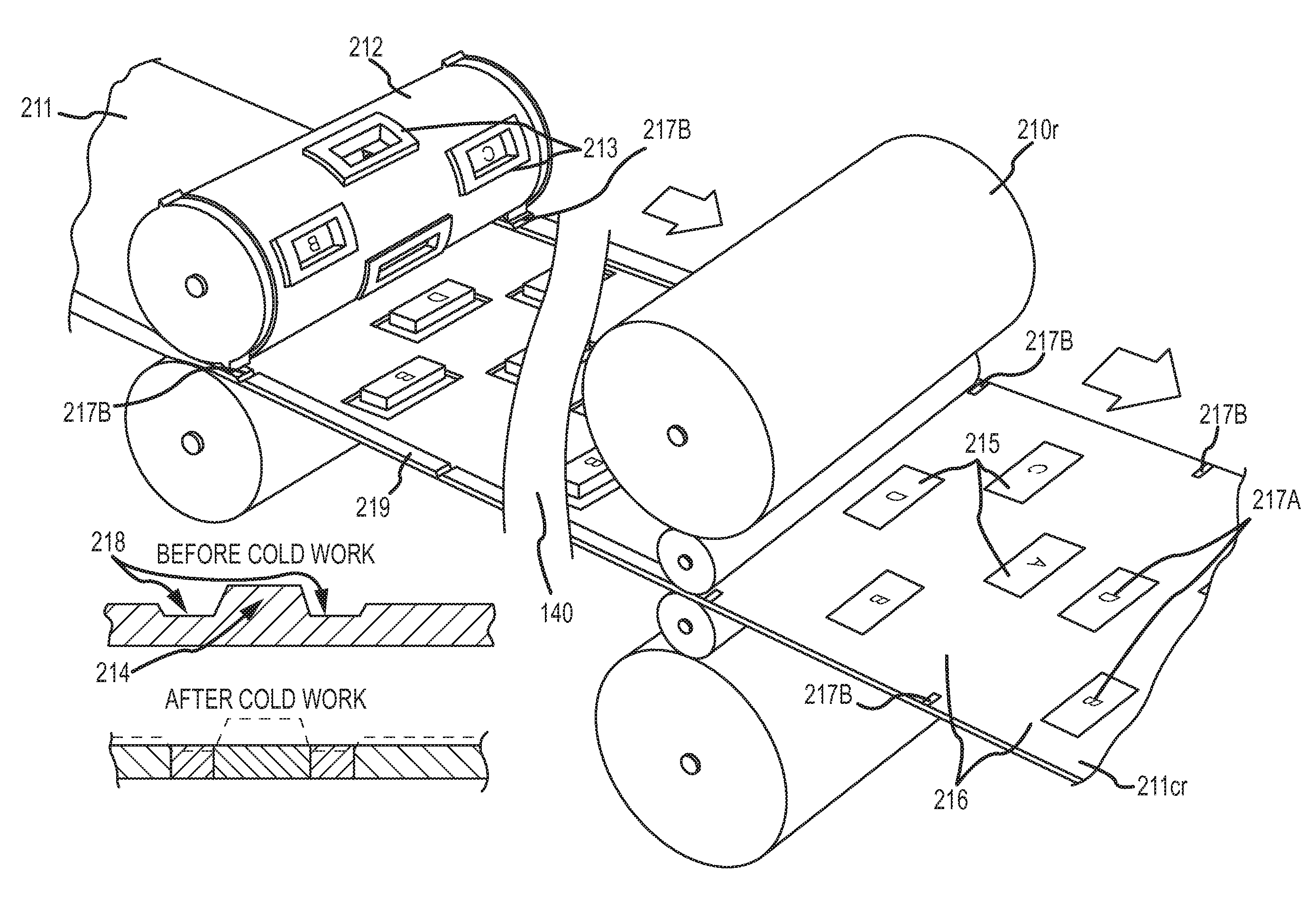

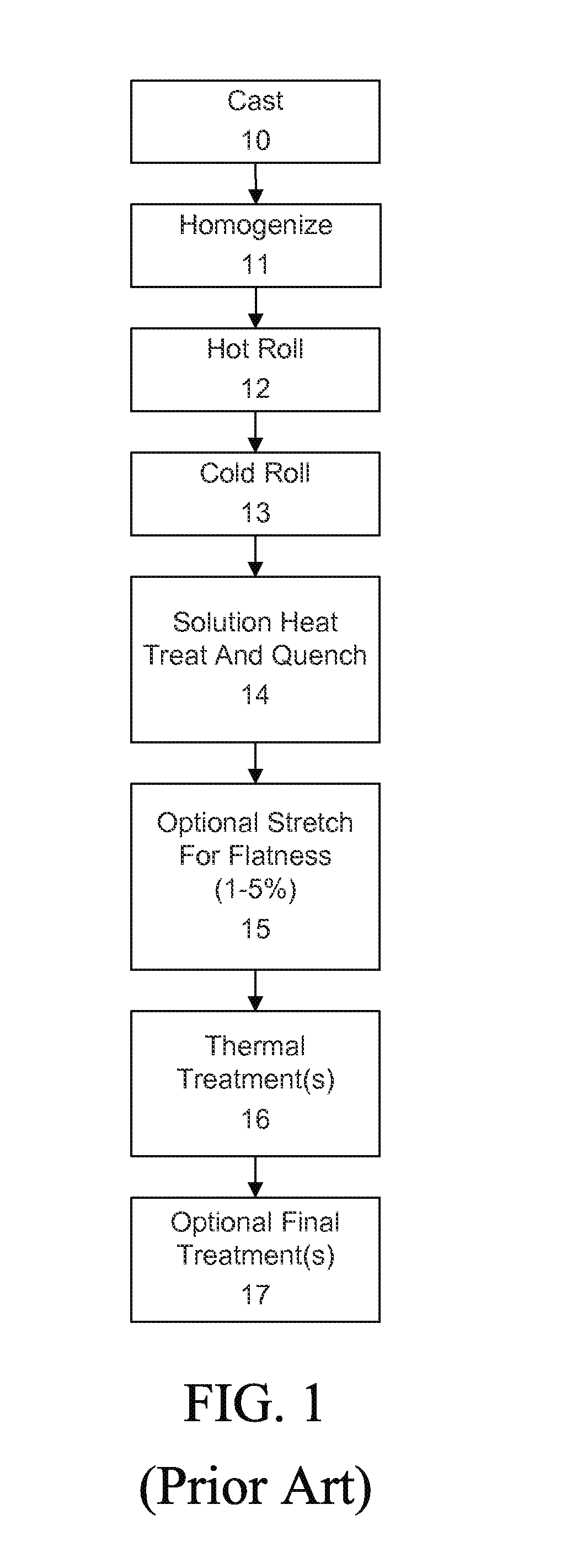

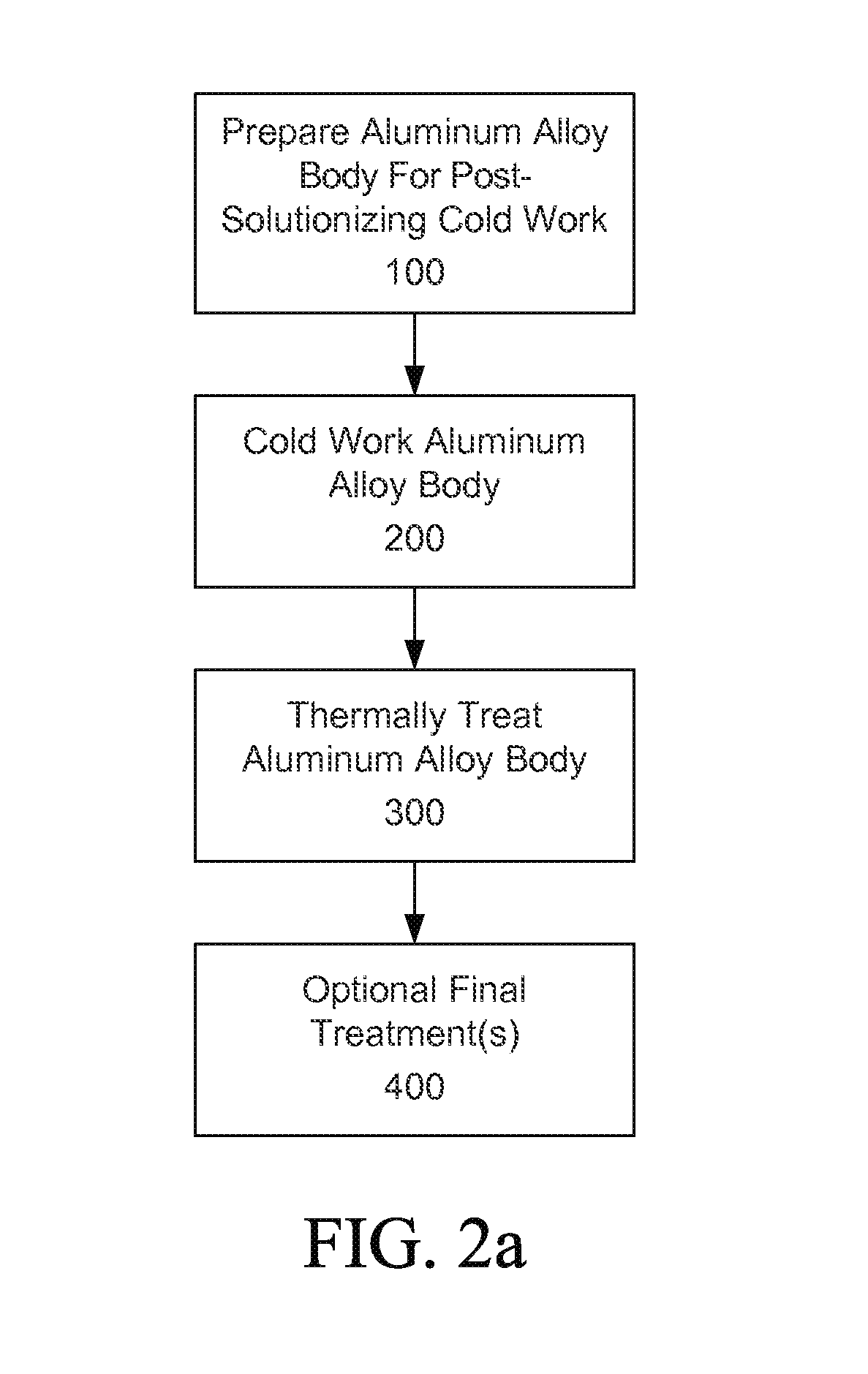

Method used

Image

Examples

example 1

Testing of 2xxx Al—Li Alloy with New Process

[0453]A 2xxx Al—Li alloy having the composition listed in Table 5 is cast, homogenized, and hot rolled into plate / sheet having intermediate gauges of about 0.53 inch, 0.32 inch, 0.16 inch (×2), and 0.106 inch, respectively. One of the 0.16 inch samples (the control) is then cold rolled to a final gauge of about 0.08 inch, solution heat treated by soaking at about 940° F. for about 120 minutes, followed by a cold water quench. The control sample is then stretched 1-2%.

TABLE 5Composition of 2xxx Al—Li alloy (all values in weight percent)OtherOthersSiFeCuMgZnZrLiAgMnEachTotalBal.0.020.023.720.810.350.080.760.360.31≦0.05≦0.15Al

The other samples are first solution heat treated (by the same process) and then cold rolled to a final gauge of 0.08 inch, representing about 85%, 75%, 50%, and 25% cold work, respectively. All samples are naturally aged for about four days, and then thermally treated at three temperatures (250° F., 290° F., and 330° F....

example 2

Surface Roughness of 2xxx+Li Alloy

[0465]The surface roughness of a 2199 was tested. Specifically, a 2199 ingot was hot rolled to intermediate gauge, and then split into a first set and a second set. The first set was processed in accordance with conventional practices, i.e., cold rolled to final gauge and then solutionized. Some of the first set are then stretched a small amount for flatness (about 2%), and then thermally treated (“the 1S-A pieces”). Others of the first set are stretched a small amount for flatness (about 2%) and then naturally aged to a substantially stable condition (“the 1S-B pieces”). The second set of materials were processed according to the new processes disclosed herein, i.e., solutionized, then cold rolled to final gauge, either about 50% or about 75% (the “2S-50” and “2S-75” pieces, respectively). Some of the 2S-50 pieces are naturally aged (the “2S-50-NA pieces”) and some of the 2S-50 pieces are thermally treated (the “25-50-TT pieces”). Likewise, some of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com