Aluminum alloy structure material and preparation thereof

A technology of structural materials and aluminum alloys, which is applied in the manufacture of ground vehicles and space vehicle structural products, low-density and high-strength aluminum alloy structural materials and their preparation, can solve the problems of inability to meet the design requirements for weight reduction, difficulty in the strength of structural materials, and Low strength and other problems, to achieve the effect of improving high-cost and complicated technical routes, scientific and reasonable formula design, and shortening the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

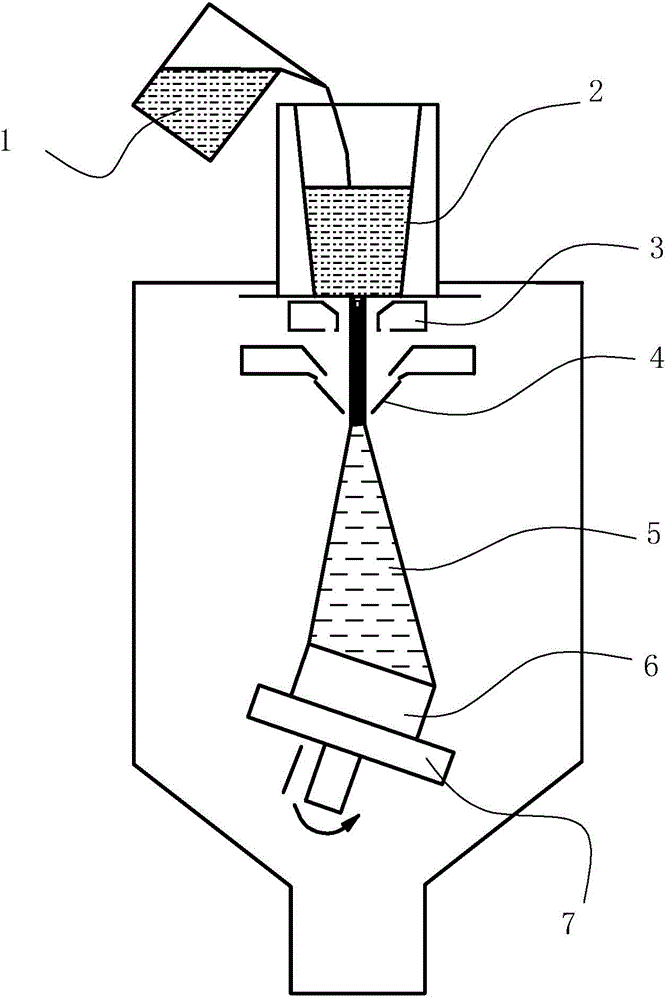

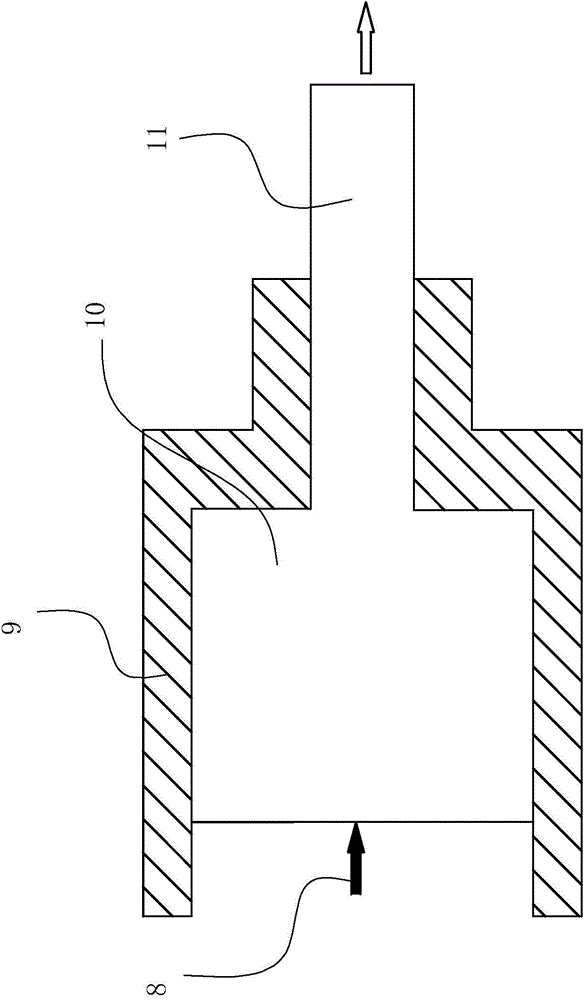

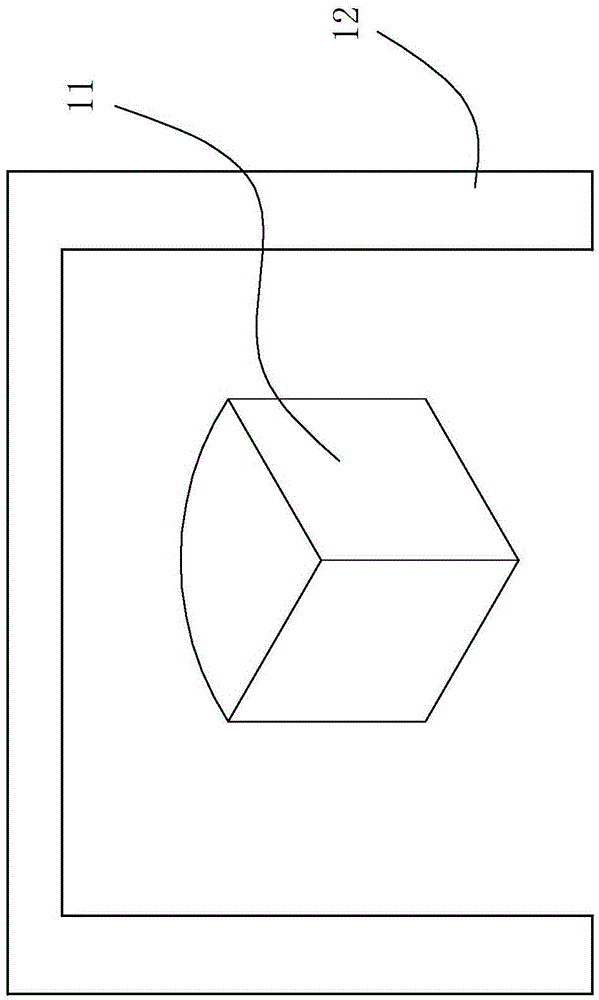

[0059] A method for preparing an aluminum alloy structural material, specifically:

[0060] 1. Alloy composition setting: (weight percentage):

[0061] AL-Mg-Si-Mn-Ti alloy:

[0062] Mg: 10.5% ~ 17.4%; and containing Be: 0.01% ~ 0.05%, based on magnesium charge;

[0063] Si: 1.0% to 5.0%;

[0064] Mn: 0.3% ~ 0.8%;

[0065] Ti: 0.15% to 0.25%;

[0066] Al: the balance of aluminum alloy and unavoidable impurities.

[0067] where the density estimate is calculated as:

[0068] The main contribution to the reduction of density ρ includes the combined effect of the contribution of the density value of each component element and the addition amount. Simplifies to:

[0069] ρ=G / Σ(W i / ρ i ) (1)

[0070] Where G is the total amount of the ingredient formula, which is calculated as 100% for the convenience of calculation;

[0071] W i Add weight percentage for each component in the ingredient formula;

[0072] ρ i is the density value of each component in the composition...

Embodiment 1

[0118] The ingredient formulations of Example 1, Example 2 and Example 3 are shown in Table 1.

[0119] Table 1 each embodiment chemical composition (wt%)

[0120]

[0121] The mechanical performance characteristics of each embodiment are shown in Table 2.

[0122] The characteristics of mechanical properties of each embodiment of table 2

[0123] Example

R m / N / mm 2

R p-1 / N / mm 2

A / %

ρ / g / cm 3

Example 1

555

485

32

2.53

Example 2

630

530

25

2.49

Example 3

670

595

11

2.48

[0124] The microstructure characteristics of each embodiment are shown in Table 3.

[0125] The microstructural characteristics of each embodiment of table 3

[0126]

[0127]

[0128] Take embodiment 2 as an example to do component design:

[0129] Density estimate calculation:

[0130] Al content is 100% - (15.0% + 3.0% + 0.5% + 0.20%) = 81.3%;

[0131] The density of Al is 2.699g / cm...

Embodiment 2

[0136] Then embodiment 2 alloy density:

[0137] ρ=G / Σ(W i / ρ i )=100 / (15.0 / 1.74+3.0 / 2.34+0.5 / 7.4+0.20 / 4.54+81.3 / 2.699)=2.48g / cm 3

[0138] Example 2 Alloy Strength Prediction Calculation:

[0139] R m =35MPa / %×W j +100~300MPa≥625MPa.

[0140] Taking Example 2 as an example to do batching calculation: smelting 120kg.

[0141] 1) The chemical composition of Example 2 is as follows:

[0142] Mg: 15.0%; Si: 3.0%; Mn: 0.50%; Ti: 0.20%; Al: the balance is aluminum alloy and other unavoidable impurities.

[0143] 2) The amount of each alloy element required in the alloy is:

[0144] According to the charge of 120 kg of furnace charge, the ingredients are calculated, and the weight of the alloy elements that need to be added is:

[0145] Mg: 18.0 kg; Si: 3.6 kg; Mn: 0.6 kg; Ti: 0.24 kg; Al: the balance is 120 kg - the total algebraic sum of the above alloy elements (22.44 kg) is 97.56 kg.

[0146] 3) Because silicon and manganese are added in the form of intermediate alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com