Two-stage aging process of Al-Zn-Mg-Cu-Zr-Er alloy

A dual-stage aging and process technology, applied in the field of non-ferrous metals, can solve the problems of poor corrosion, low toughness of high-strength aluminum alloys, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

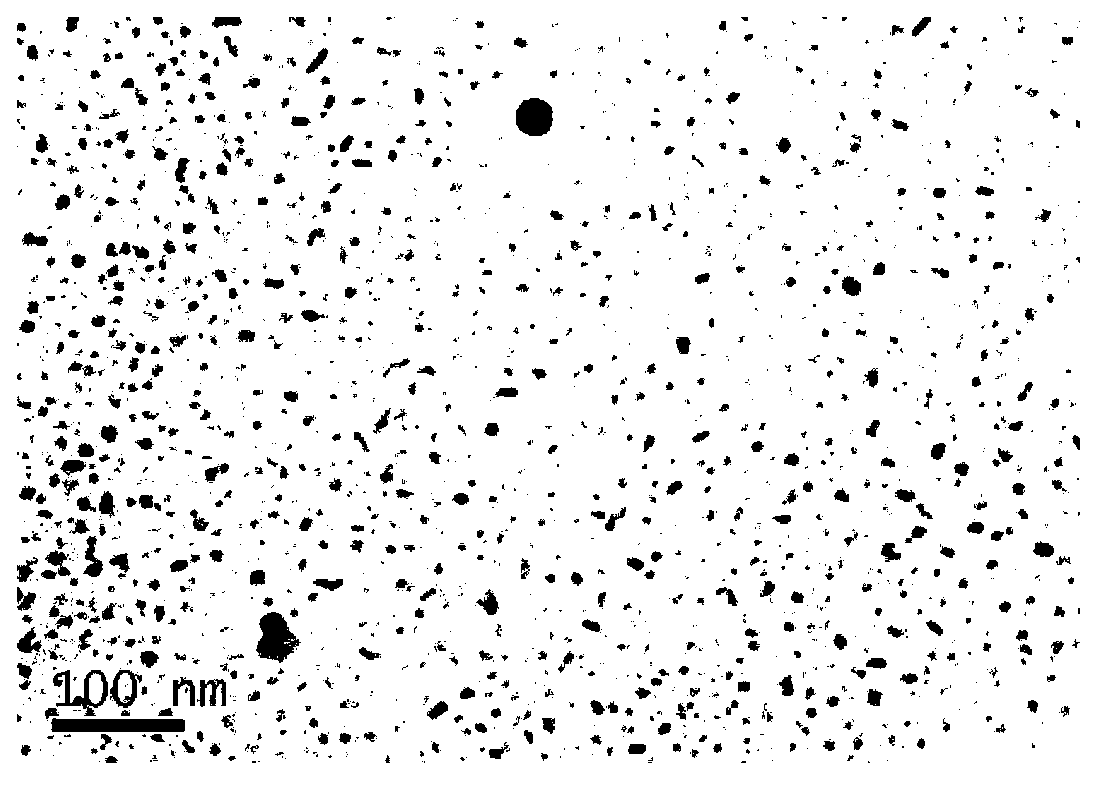

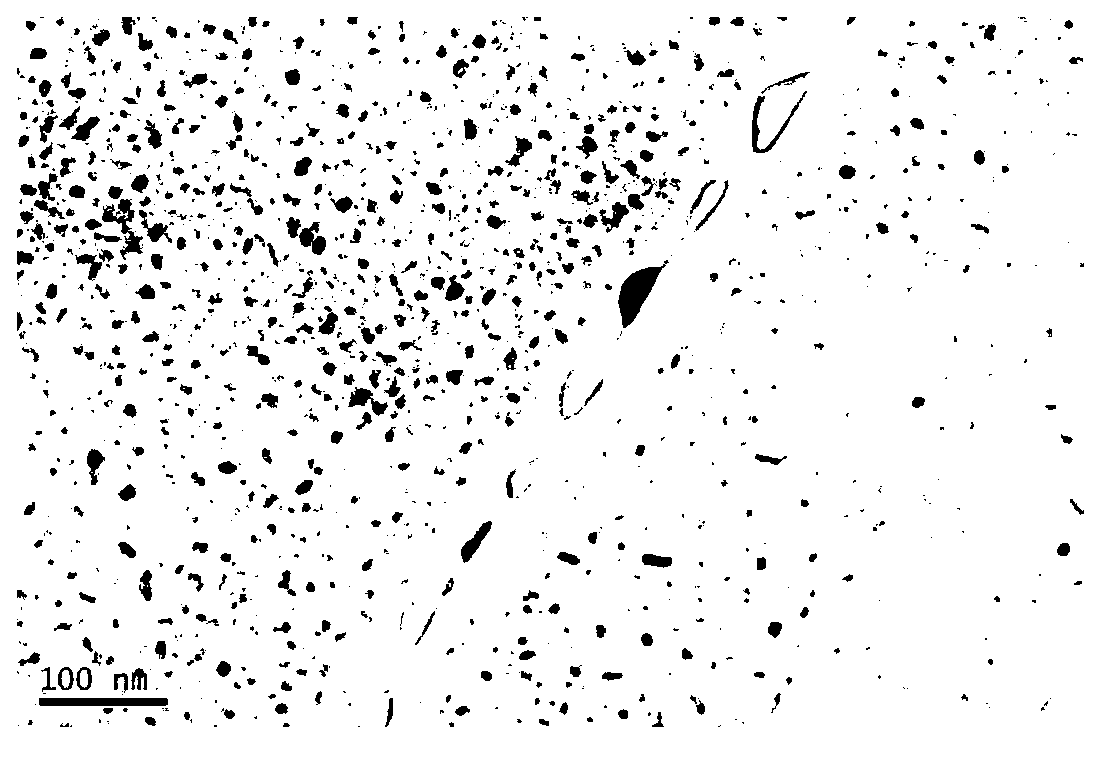

Image

Examples

Embodiment 1

[0014] 1) For the mass percentage content: Zn5.6%, Mg2.6%, Cu1.5%, Zr0.2%, Er0.2%, Mn0.15%, a small amount of impurities Fe, Si, the balance is Al The alloy was solution treated at 470℃ / 2h, and then quenched in water at room temperature;

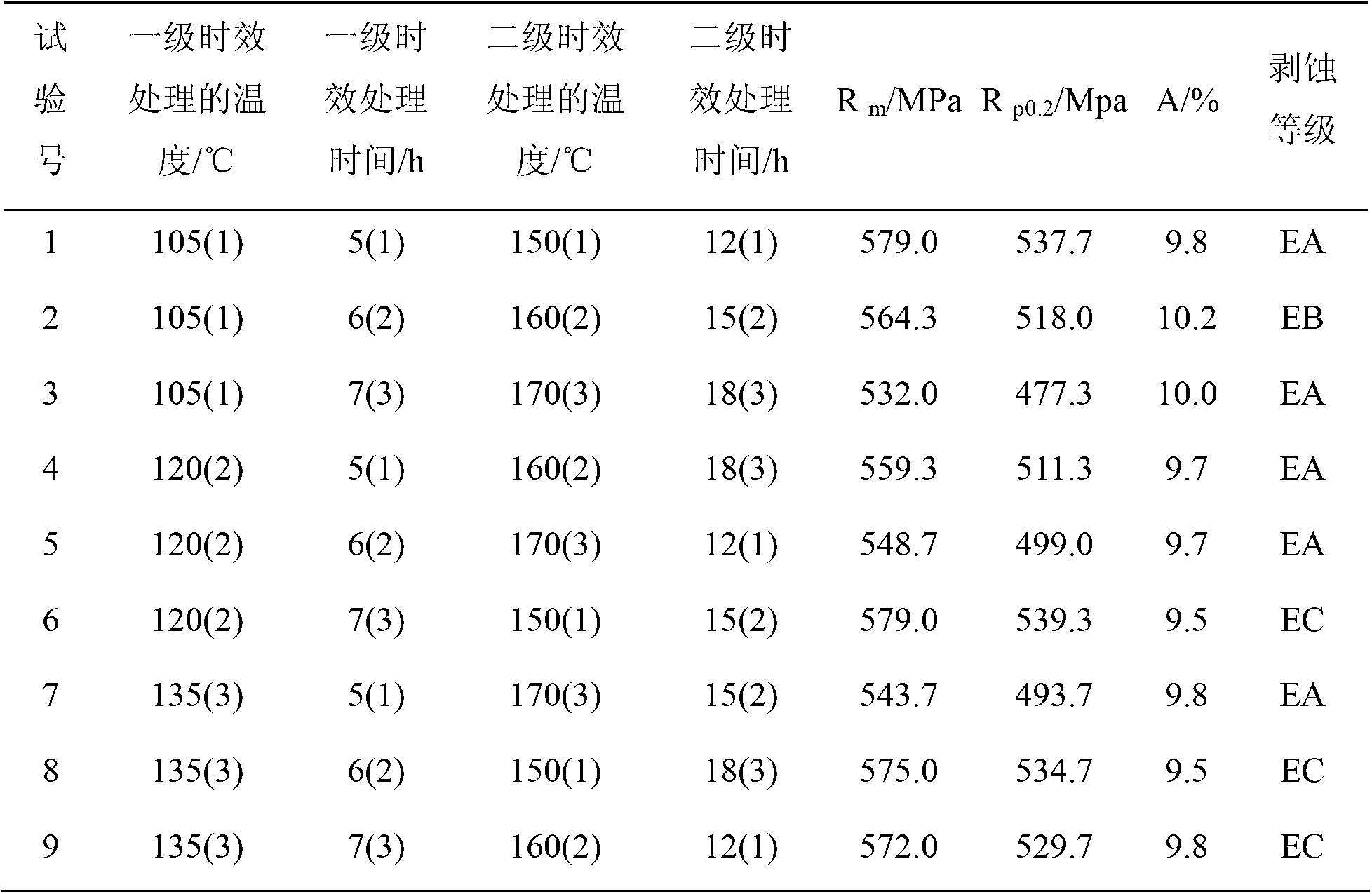

[0015] 2) For the Al-Zn-Mg-Cu-Zr-Er alloy obtained in step 1), carry out the 9 sets of double-stage aging orthogonal tests shown in Table 1, according to the "Metallic Materials Tensile Test Method at Room Temperature" (GB / T228- 2002) for tensile performance test, the data are listed in Table 1. The exfoliation corrosion test was carried out according to the "Exfoliation Corrosion Test Method for Aluminum Alloy Processed Products" (GB / T22639-2008), and the exfoliation corrosion grades are listed in Table 1.

[0016] Table 1 Orthogonal design test scheme and test results

[0017]

[0018] The results of the double-stage aging orthogonal test in Table 1 were analyzed using the comprehensive balance method, and it was predicted that the Al...

Embodiment 2

[0020] 1) For the mass percentage content: Zn5.6%, Mg2.6%, Cu1.5%, Zr0.2%, Er0.2%, Mn0.15%, a small amount of impurities Fe, Si, the balance is Al The alloy was solution treated at 470℃ / 2h, and then quenched in water at room temperature;

[0021] 2) After the Al-Zn-Mg-Cu-Zr-Er alloy obtained in step 1) is subjected to a double-stage aging treatment at 105°C×5h+170°C×12h, according to the "Metallic Materials Tensile Test Method at Room Temperature" (GB / T228-2002) for tensile test, the data are listed in Table 2. The exfoliation corrosion test was carried out according to the "Exfoliation Corrosion Test Method for Aluminum Alloy Processed Products" (GB / T22639-2008), and the exfoliation corrosion grades are listed in Table 2.

[0022] Table 2105℃×5h+170℃×12h double-stage aging test test results

[0023]

[0024] The test results show that the Al-5.6Zn-2.6Mg-1.5Cu-0.2Zr-0.2Er alloy has good mechanical properties and exfoliation corrosion properties after double-stage aging t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com