New method for eliminating aluminium alloy workpiece residual stress

A technology of residual stress and a new method, applied in the fields of metal processing, cryogenic treatment and heat treatment, can solve the problems of cold work hardening of molding deformation, poor stress relief effect, and extremely high operation requirements, so as to improve strength and toughness and eliminate residual stress. , The effect of stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

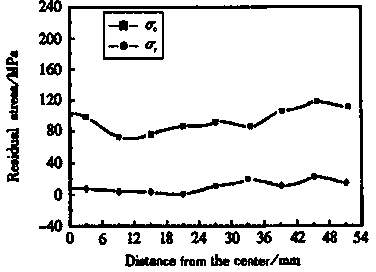

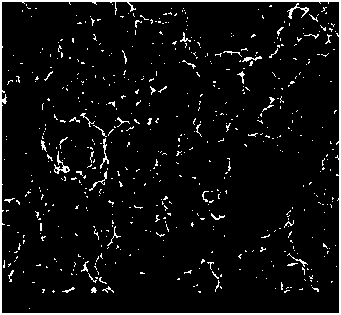

[0029] A 6082-T6 aluminum alloy plate of 120 mm×120 mm×4 mm was subjected to solid solution at 540°C for 1 hour, cooled to room temperature with water, and placed in a program-controlled cryogenic box (transfer time not exceeding 5s), at a temperature of 6°C / min. The speed is cooled from room temperature to -190°C and then kept for 4 hours; then the sample is taken out and placed in boiling water at 100°C for 20 minutes, and the transfer time does not exceed 5s; Speed heating to 175°C, heat preservation for 7 hours, and turn off the power; after the furnace temperature and the test piece are cooled to room temperature, take out the test piece and repeat the three-step operation after solid solution treatment twice to obtain the 6082 plate of the present invention. The average hardness of the specimens treated by this method increased from the initial 120HV to 135HV (test force 0.98N, hold for 15s); the average tensile strength increased from the initial 363MPa to 419MPa...

Embodiment 2

[0031] Extruded 6061-T6 aluminum alloy extruded "T" profile of 100mm×100mm×2mm automobile body structural parts was subjected to solid solution at 530°C for 100min, cooled to room temperature with water, and placed in a program-controlled cryogenic box (the transfer time should not exceed 5s), cooling from room temperature to -175°C at a rate of 7°C / min and then holding for 12h; then take out the sample and put it in a 250°C salt bath furnace for 15min, the transfer time should not exceed 5s; take out the sample from the salt bath furnace Put it in an electric drying oven and heat it to 170°C at a rate of 5°C / min, then keep it warm for 8 hours, and then turn off the power; after the furnace temperature and the specimen cool down to room temperature, take out the specimen and repeat the three-step operation after solid solution treatment twice. Obtain the 6061 T profile of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com