High-strength, high-conductivity and high-extensibility rare earth copper alloy and preparation method thereof

A high-extensibility, high-conductivity technology, applied in high-conductivity, high-extensibility rare-earth copper alloys and their preparation, copper-based alloys and their preparation, and high-strength fields, can solve the problems of poor comprehensive performance of copper-based alloys and achieve improved comprehensive performance. properties, improving alloy properties, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

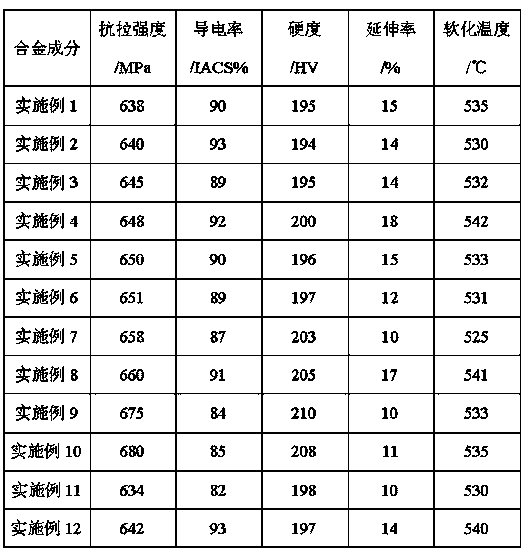

Examples

preparation example Construction

[0026] (1) Preparation of master alloy: Put copper and rare earth elements into a vacuum non-consumable electrode arc melting furnace for melting, and vacuumize until the pressure in the furnace is 5×10 -2 Pa, then fill in nitrogen until the pressure in the furnace is 0.05MPa, control the smelting current to 400~500A, and the smelting voltage is 20~40V to obtain a Cu-rare earth master alloy for future use;

[0027] (2) Melting and mold casting: put copper, chromium, zirconium, nickel, titanium, manganese and the Cu-rare earth master alloy prepared in step (1) into a high-frequency vacuum melting furnace for melting, and vacuumize until the pressure in the furnace is 5×10 -2 Pa, then fill the furnace with nitrogen until the pressure in the furnace is 0.05MPa, control the melting temperature to 1200-1300°C, pour into the casting mold after melting, and form an ingot, and the pouring temperature is controlled at 1100-1200°C;

Embodiment 1

[0036] The specific preparation method is:

[0037] (1) Preparation of master alloy: Put copper and rare earth elements into a vacuum non-consumable electrode arc melting furnace for melting, and vacuumize until the pressure in the furnace is 5×10 -2 Pa, then charge into nitrogen until the pressure in the furnace is 0.05MPa, control the smelting current to 450A, and the smelting voltage is 30V, to obtain Cu-rare earth master alloy, for subsequent use;

[0038] (2) Melting and mold casting: put copper, chromium, zirconium, nickel, titanium, manganese and the Cu-rare earth master alloy prepared in step (1) into a high-frequency vacuum melting furnace for melting, and vacuumize until the pressure in the furnace is 5×10 -2 Pa, then fill the furnace with nitrogen until the pressure in the furnace is 0.05MPa, control the melting temperature to 1200°C, pour into the casting mold after melting, and form an ingot, and the pouring temperature is controlled at 1100°C;

[0039] (3) Cast...

Embodiment 2

[0046] The specific preparation method is:

[0047] (1) Preparation of master alloy: Put copper and rare earth elements into a vacuum non-consumable electrode arc melting furnace for melting, and vacuumize until the pressure in the furnace is 5×10 -2 Pa, then charge nitrogen into the furnace until the pressure is 0.05MPa, control the smelting current to 450A, and the smelting voltage is 35V, to obtain a Cu-rare earth master alloy for subsequent use;

[0048] (2) Melting and mold casting: put copper, chromium, zirconium, nickel, titanium, manganese and the Cu-rare earth master alloy prepared in step (1) into a high-frequency vacuum melting furnace for melting, and vacuumize until the pressure in the furnace is 5×10 -2 Pa, then fill the furnace with nitrogen until the pressure in the furnace is 0.05MPa, control the melting temperature to 1250°C, pour into the casting mold after melting, and form an ingot, and the pouring temperature is controlled at 1150°C;

[0049] (3) Castin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com