Anti-exfoliation corrosion high-strength aluminum-zinc-magnesium-copper alloy and heat treatment process

A technology of exfoliation corrosion and aluminum-zinc-magnesium, which is applied in the fields of exfoliation corrosion-resistant high-strength aluminum-zinc-magnesium-copper alloy and heat treatment process, aluminum alloy and heat treatment process, and can solve problems such as unfavorable industrial production applications, low stress corrosion resistance, complex aging process, etc. problems, to achieve the effect of short aging time, high production efficiency and simple aging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

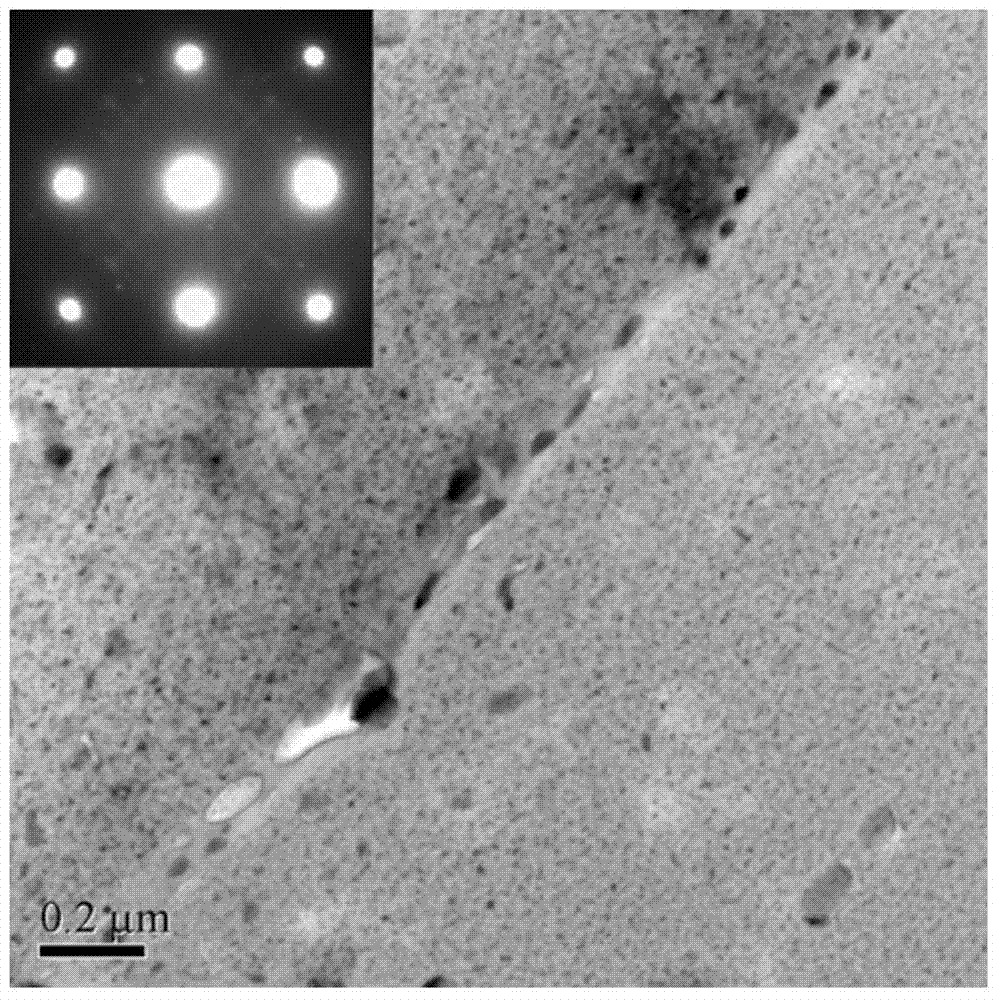

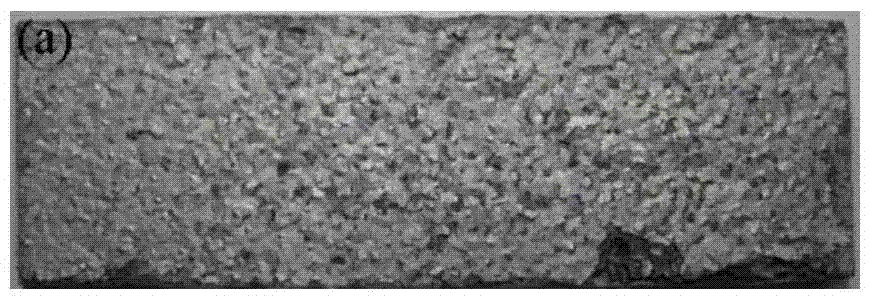

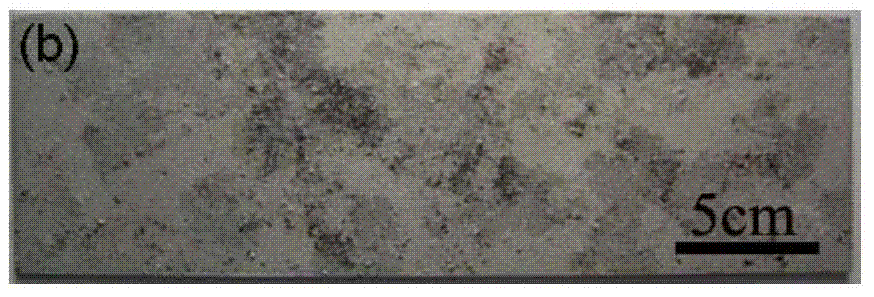

[0040] The composition of alloy 1 is (weight percent): Zn: 6.1%, Mg: 2.49%, Cu: 1.9%, Cr: 0.25%, Ti: 0.04%, and the balance is Al. The weight ratio of Zn / Mg in this alloy is 2.45; 1.5h solution treatment at 470°C, 3% pre-deformation after water quenching, then aging at 122°C for 3 hours, followed by aging at 165°C for 12 hours. Various performance indicators obtained after this treatment: tensile strength 520MPa, yield strength 468Mpa, elongation 12.8%, electrical conductivity 39.9%IACS. According to the ASTM G34-01 standard, the corrosion grade for exfoliation corrosion evaluation is P, that is, pitting corrosion. There are discontinuous corrosion points on the surface of the sample, see Figure 2.

Embodiment 2

[0042] The composition of alloy 2 is (weight percent): Zn: 5.5%, Mg: 2.3%, Cu: 1.5%, Cr: 0.21%, Ti: 0.03%, and the balance is Al. The weight ratio of Zn / Mg in this alloy is 2.39; solution treatment is carried out at 470°C for 1h, and 2% pre-deformation is carried out immediately after water quenching, then aged at 122°C for 3 hours, followed by aging at 170°C for 10 hours. Various performance indicators obtained after this treatment: tensile strength 509Mpa, yield strength 441Mpa, elongation 12.1%, electrical conductivity 40.1%IACS, corrosion grade P.

Embodiment 3

[0044] Alloy 2 was solution treated at 465°C for 2 hours, pre-deformed by 3% immediately after water quenching, and then aged at 122°C for 4 hours, followed by aging at 165°C for 12 hours. Various performance indicators obtained after this treatment: tensile strength 501Mpa, yield strength 429Mpa, elongation 12.2%, electrical conductivity 42%IACS, corrosion grade P.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com