Two-stage aging technology of exfoliation corrosion resistant erbium-containing Al-Zn-Mg-Cu alloy

A two-stage aging and exfoliation corrosion technology, which is applied in the field of non-ferrous metal materials, can solve the problems of low toughness and poor corrosion resistance, and achieve the effect of high strength and superior exfoliation corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

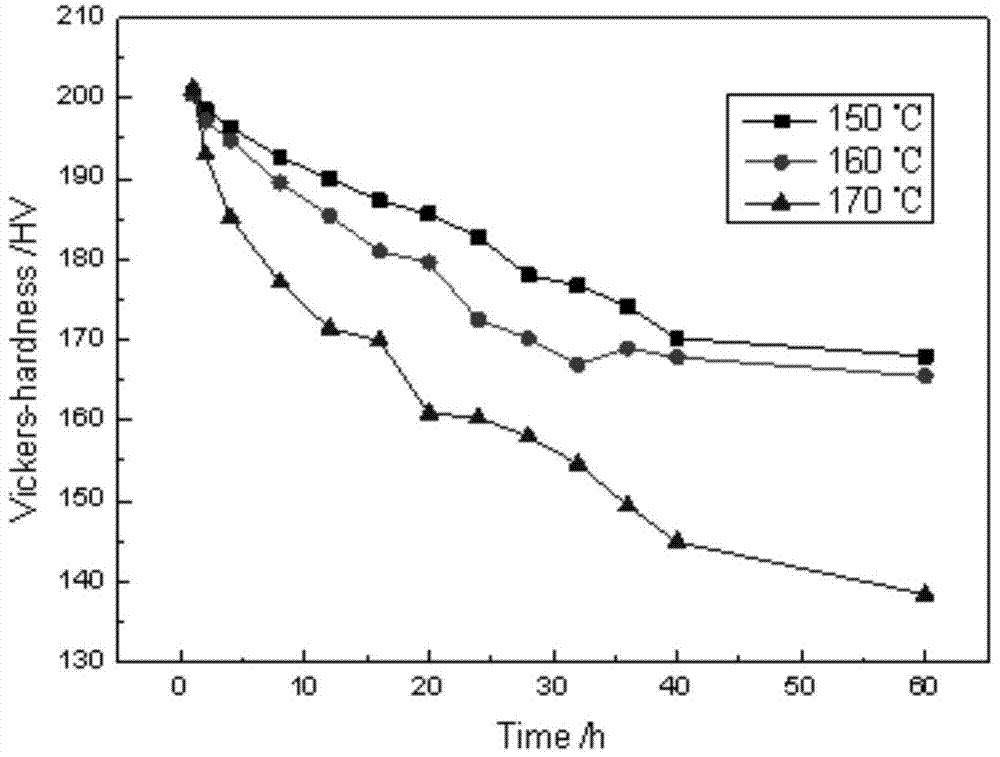

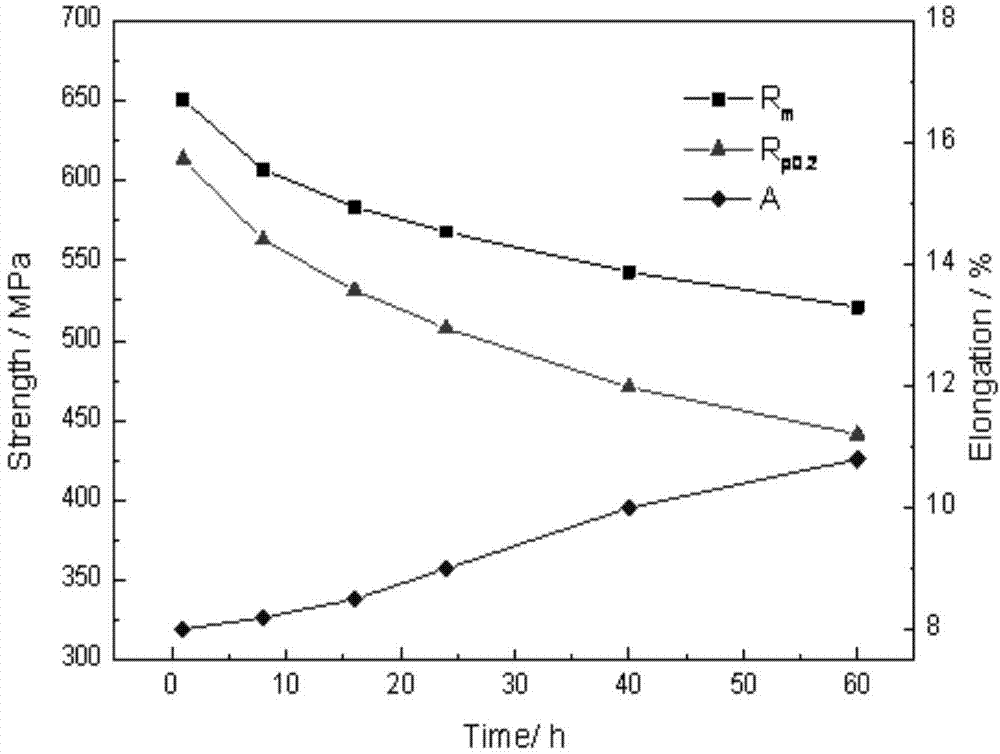

[0015] After the alloy is solution quenched, it is kept at 120°C for 4h; then the alloy is kept at 150°C, 160°C and 170°C for 1-60h respectively. figure 1 For the corresponding aging hardness curve, Table 1 shows the exfoliation corrosion rating of the alloy after double-stage aging.

[0016] Table 1 Exfoliation corrosion rating of the alloy after the second aging

[0017]

[0018] Compared figure 1 From Table 1, it can be found that with the prolongation of the secondary aging time and the increase of temperature, the hardness of the alloy gradually decreases, and the higher the temperature, the faster the decrease; while the exfoliation corrosion resistance of the alloy is significantly improved, and gradually becomes weaker in the early aging period. Well, after a certain point it starts to get worse. comprehensive figure 1 And Table 1, the alloy in the second stage of aging is 160 ℃ for a certain period of time, the exfoliation corrosion resistance is better than oth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com