Er-containing high-strength anti-corrosion Al-Zn-Mg aluminum alloy and preparation method

An aluminum alloy, corrosion-resistant technology, applied in the field of non-ferrous metal materials, can solve the problems of high price, hindering the migration and restriction of dislocations and grain boundaries, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] An Al-Zn-Mg series alloy containing Er, the alloy composition mass percentage is: Zn: 4.03%, Mg: 2.09%, Cu: 0.35%, Er: 0.15%, Zr: 0.18%, and the balance is Al.

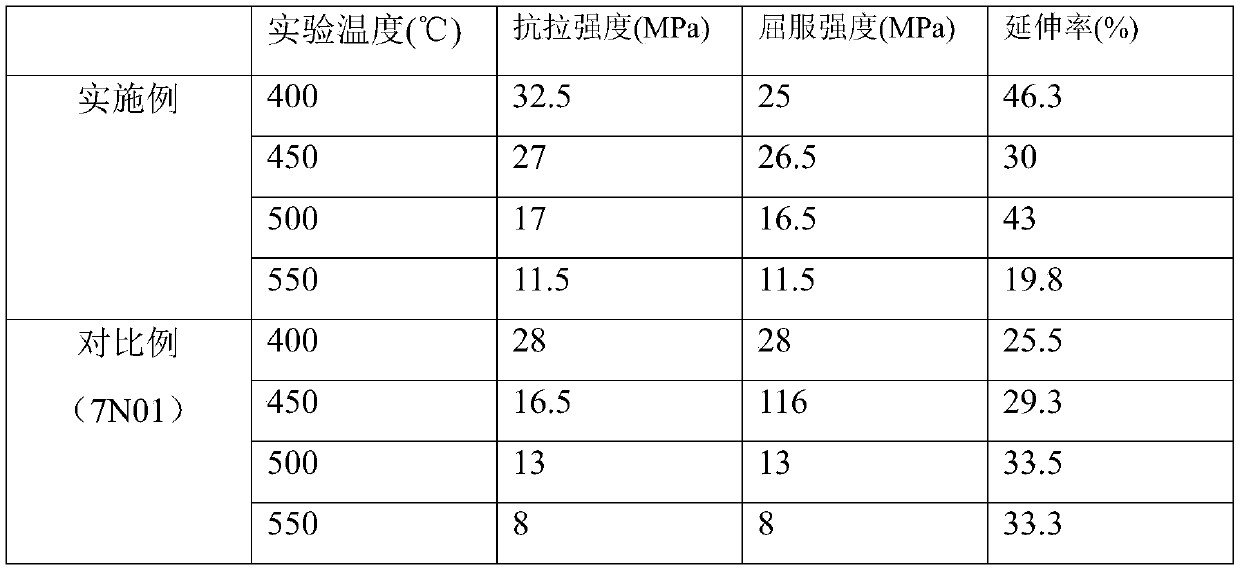

[0021] Melting and casting in a resistance furnace, skimming and stirring, pouring into a mold; putting the ingot into an annealing furnace for homogenization annealing, the process is 280°C / 10h+470°C / 20h, the high temperature properties of the alloy after homogenization are shown in Table 1 , followed by hot rolling, the reduction is 90%, and the hot rolling temperature is 500°C.

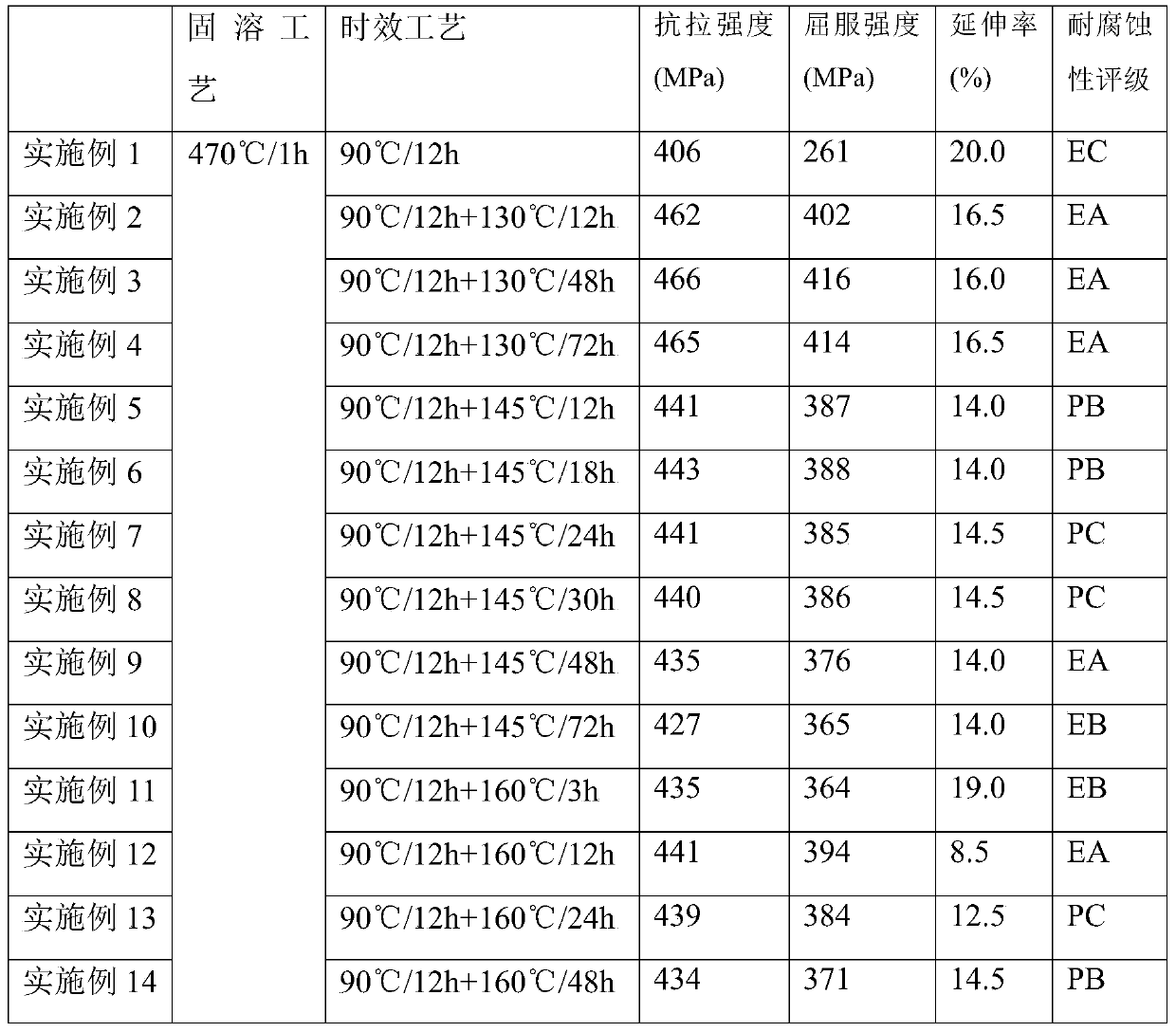

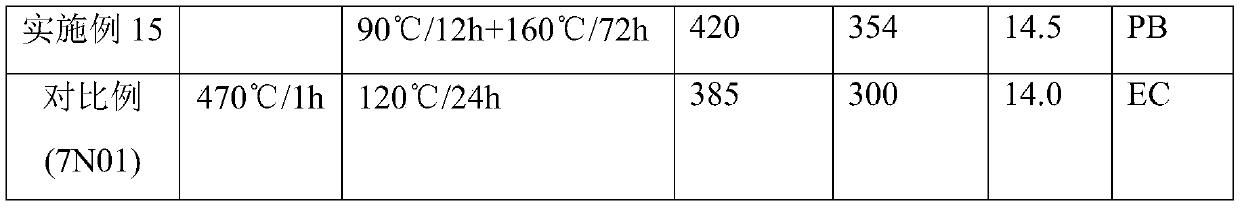

[0022] Then the solid solution process is 470°C / 1h, water quenching; then the aging process is 90°C / 12h, and its mechanical properties and corrosion resistance are shown in Table 2.

Embodiment 2

[0024] The process from casting to hot rolling is the same as in Example 1, then the solution process is 470°C / 1h, water quenching; and the aging process is 90°C / 12h+130°C / 12h. The mechanical properties and corrosion resistance are shown in Table 2.

Embodiment 3

[0026] The process from casting to hot rolling is the same as in Example 1, then the solution process is 470°C / 1h, water quenching; and the aging process is 90°C / 12h+130°C / 48h. The mechanical properties and corrosion resistance are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com