Preparation method of beta-gamma TiAl alloy sheet containing fine lath-like γ-recrystallized structure

A technology of recrystallization structure and alloy sheet, which is applied in the field of preparing TiAl alloy sheet, can solve the problems of low alloy fracture toughness, complex heat treatment process, and low tensile strength, so as to improve the tensile performance at room temperature, save the tedious heat treatment process, The effect of uniform and fine tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

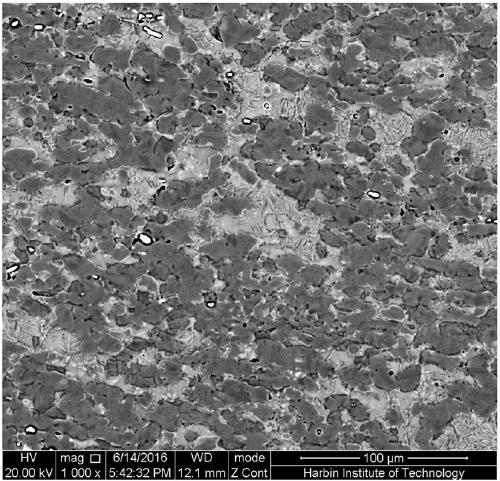

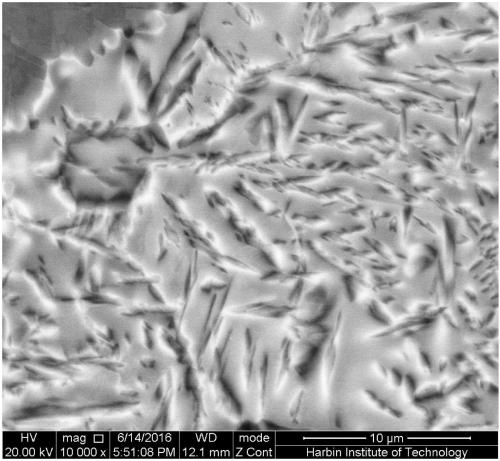

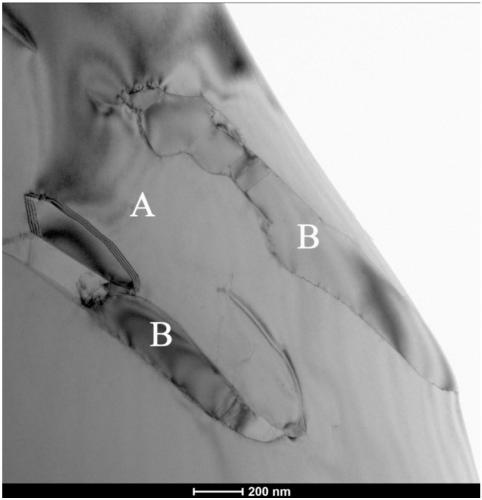

[0023] Specific embodiment one: the present embodiment is the preparation method of the beta-gammaTiAl alloy sheet material that contains fine lath-like γ recrystallization structure, specifically carries out according to the following steps:

[0024] 1. Preparation of TiAl alloy blank: forging and opening the TiAl alloy prefabricated blank to prepare the TiAl alloy prefabricated blank, then subjecting the TiAl alloy prefabricated blank to hot isostatic pressing, and then using mechanical processing to process the TiAl alloy prefabricated blank after hot isostatic pressing into Cuboid blank, obtains TiAl alloy blank;

[0025] The parameters of the hot isostatic pressing treatment described in step 1 are: the temperature of the hot isostatic pressing is 1000°C to 1250°C, the pressure of the hot isostatic pressing is 140MPa to 200MPa, and the time of the hot isostatic pressing is 1h to 5h;

[0026] The thickness of the TiAl alloy blank described in step 1 is 3 mm to 30 mm;

[0...

specific Embodiment approach 2

[0033] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the machining method described in step 1 is wire cutting. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0034] Specific embodiment 3: This embodiment differs from specific embodiment 1 or 2 in that: the parameters for preparing the TiAl alloy prefabricated billet by forging blank described in step 1 are: the initial forging temperature is 1220°C-1260°C, and the deformation rate is 0.005s -1 ~0.05s -1 , The total deformation is 65% to 85%. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com