Two-stage aging process of Al-5.6Zn-2.1Mg-1.2Cu-0.1Zr-0.1Er alloy

A dual-stage aging and process technology, applied in the field of non-ferrous metals, can solve problems such as the difficulty in achieving rapid temperature rise and the difficulty in ensuring the temperature consistency of the core and surface of components, and achieve good overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

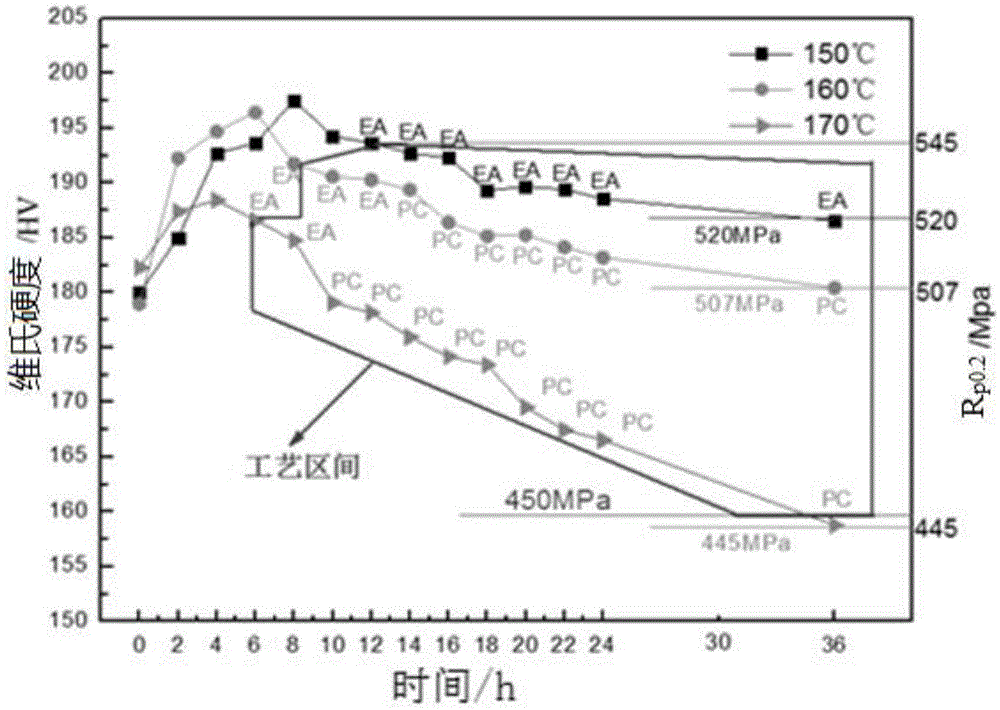

[0017] The Al-5.6Zn-2.1Mg-1.2Cu-0.1Zr-0.1Er aluminum alloy was subjected to solution treatment, raised from room temperature to 475°C, the heating rate was 2°C / min, kept for 2h, room temperature water cooling and quenching; and then carried out Two-stage aging heat treatment with slow temperature rise, the first stage of aging is raised from room temperature to 120°C, the heating rate is 1°C / min, and the temperature is kept for 5 hours; the second stage of aging is raised from 120°C to 150°C, and the heating rate is 1°C / min , heat preservation 0 ~ 36h.

Embodiment 2

[0019] The Al-5.6Zn-2.1Mg-1.2Cu-0.1Zr-0.1Er aluminum alloy was subjected to solution treatment, raised from room temperature to 475°C, the heating rate was 2°C / min, kept for 2h, room temperature water cooling and quenching; and then carried out Two-stage aging heat treatment with slow temperature rise, the first stage of aging is raised from room temperature to 120°C, the heating rate is 1°C / min, and the temperature is kept for 5 hours; the second stage of aging is raised from 120°C to 160°C, and the heating rate is 1°C / min , heat preservation 0 ~ 36h.

Embodiment 3

[0021] The Al-5.6Zn-2.1Mg-1.2Cu-0.1Zr-0.1Er aluminum alloy was subjected to solution treatment, raised from room temperature to 475°C, the heating rate was 2°C / min, kept for 2h, room temperature water cooling and quenching; and then carried out Two-stage aging heat treatment with slow temperature rise, the first stage of aging is raised from room temperature to 120°C, the heating rate is 1°C / min, and the temperature is kept for 5 hours; the second stage of aging is raised from 120°C to 170°C, and the heating rate is 1°C / min , heat preservation 0 ~ 36h.

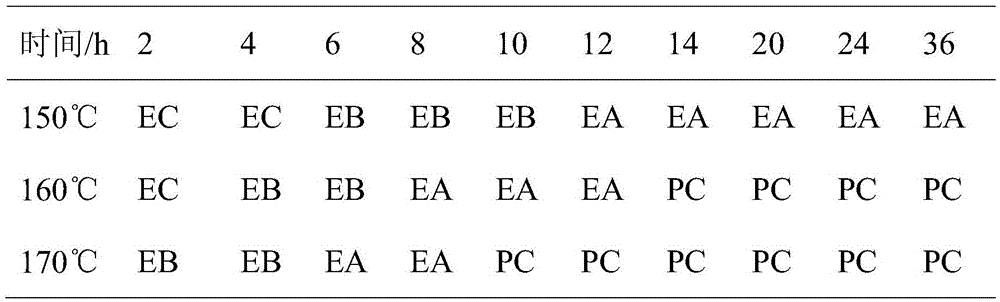

[0022] Table 1 is the exfoliation corrosion resistance rating of the alloys corresponding to Examples 1, 2, and 3 after dual-stage aging treatment.

[0023] Table 1 Exfoliation Corrosion Resistance Rating of Alloys Corresponding to Examples 1, 2, and 3 After Double-Stage Aging Treatment

[0024]

[0025] It can be seen from Table 1 that the process window with good exfoliation corrosion resistance can be obtained after the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness value | aaaaa | aaaaa |

| Vickers hardness value | aaaaa | aaaaa |

| Vickers hardness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com