Method for preparing III-V chemical compound electronic device

A technology of electronic devices and compounds, which is applied in the field of high-performance semiconductor physical devices, can solve problems such as broken electronic devices, inability to meet heat dissipation, and thermal conductivity backing layer is not resistant to chemical corrosion liquid corrosion, etc., to achieve high heat dissipation and ensure integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

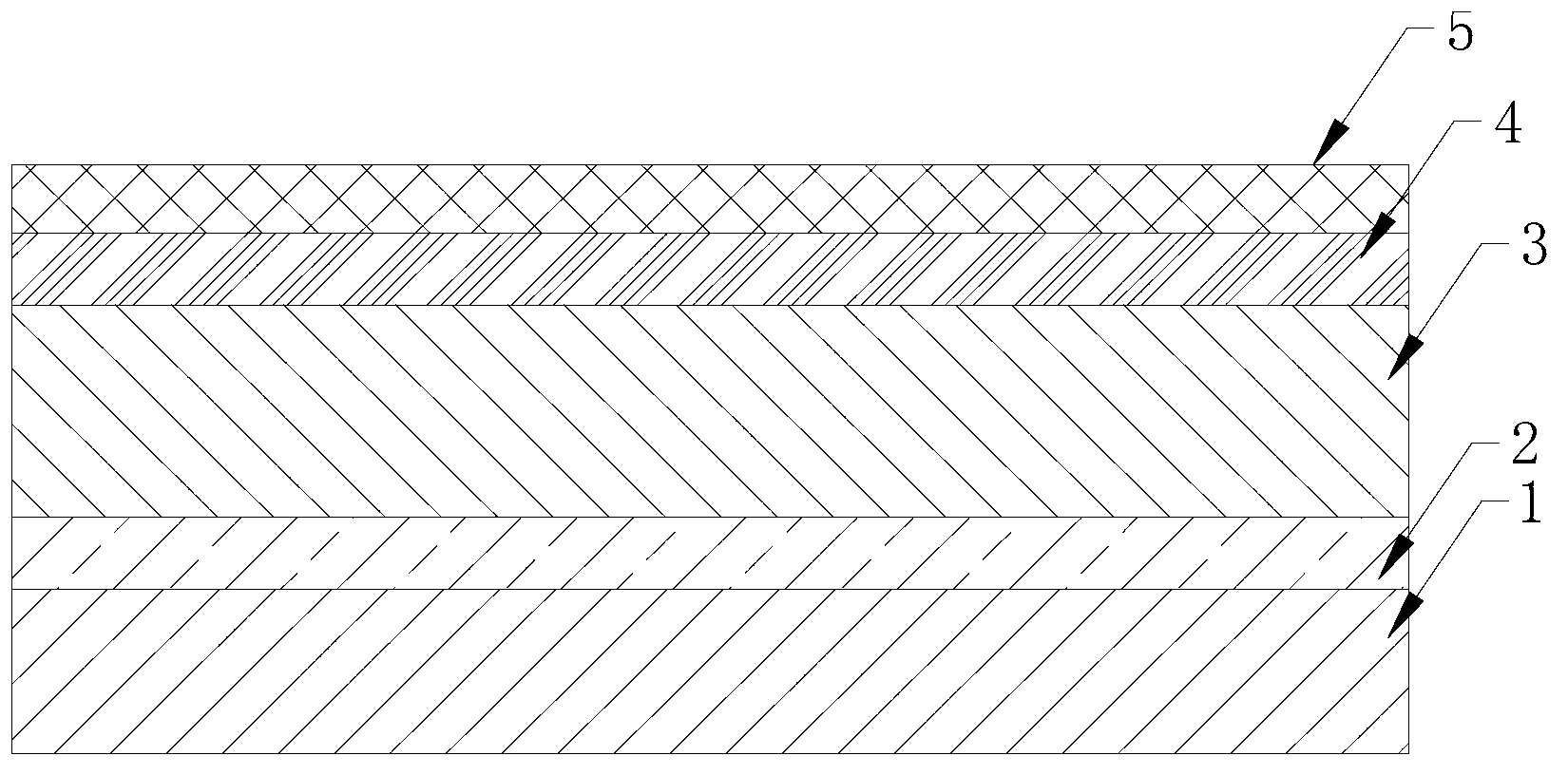

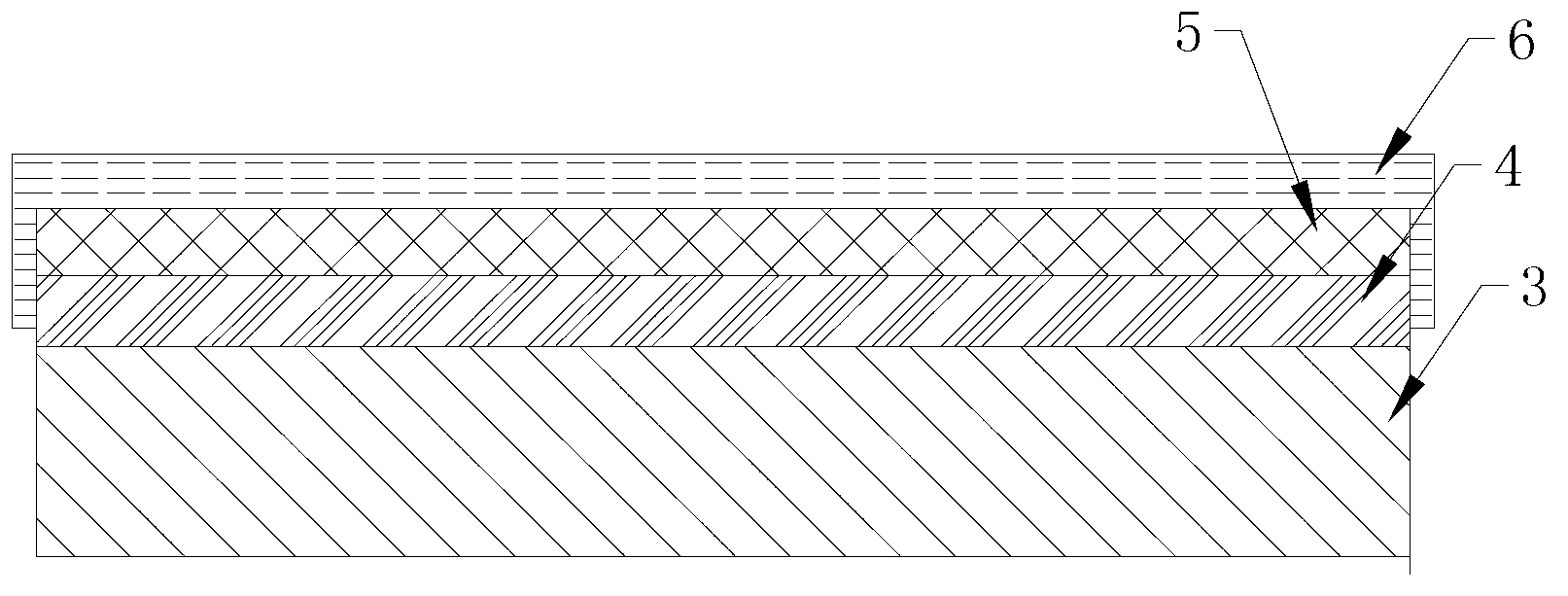

[0025] Such as Figure 1 to Figure 4 As shown,

[0026] A method for preparing a III-V compound electronic device, the method comprising:

[0027] A. Provide a substrate 1; the substrate 1 is generally a III-V compound semiconductor substrate 1, such as GaAs, etc.

[0028] B. A sacrificial layer 2 is formed on the substrate 1; the sacrificial layer 2 is epitaxially grown on the substrate 1. The sacrificial layer 2 can be corroded by a specific chemical etching solution, but the chemical etching solution will not affect the active layer 3 Cause damage. The chemical etching solution here is also called stripping etching solution.

[0029] C. An active layer 3 is formed on the sacrificial layer 2; the active layer 3 is also called a device layer and is a functional layer of an electronic device.

[0030] D. A backing layer is formed on the active layer 3. The backing layer includes a metal layer 4 bonded to the active layer 3 and a thermally conductive backing layer 5 adhered to the metal...

Embodiment 2

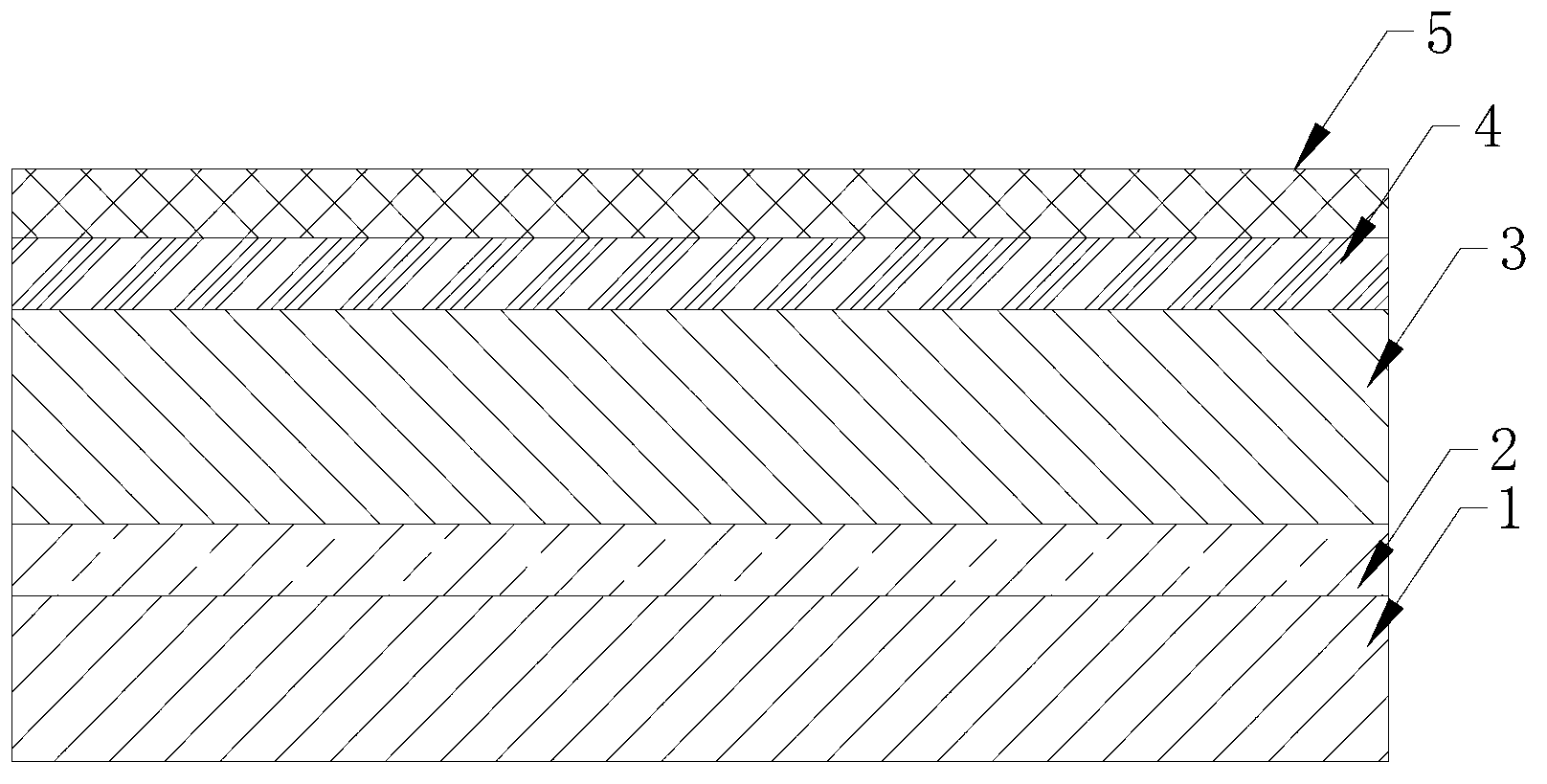

[0033] A method for preparing a III-V compound electronic device, the method comprising:

[0034] A. Provide a substrate 1; the substrate 1 is generally a III-V compound semiconductor substrate 1, such as GaAs, etc.

[0035] B. A sacrificial layer 2 is formed on the substrate 1; the sacrificial layer 2 is epitaxially grown on the substrate 1. The sacrificial layer 2 can be corroded by a specific chemical etching solution, but the chemical etching solution will not affect the active layer 3 Cause damage. The chemical etching solution here is also called stripping etching solution.

[0036] C. An active layer 3 is formed on the sacrificial layer 2; the active layer 3 is also called a device layer and is a functional layer of an electronic device.

[0037] D. Form a backing layer on the active layer 3. The backing layer includes a metal layer 4 bonded to the active layer 3 and a thermally conductive backing layer 5 adhered to the metal layer 4. When the thickness of the backing layer is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com