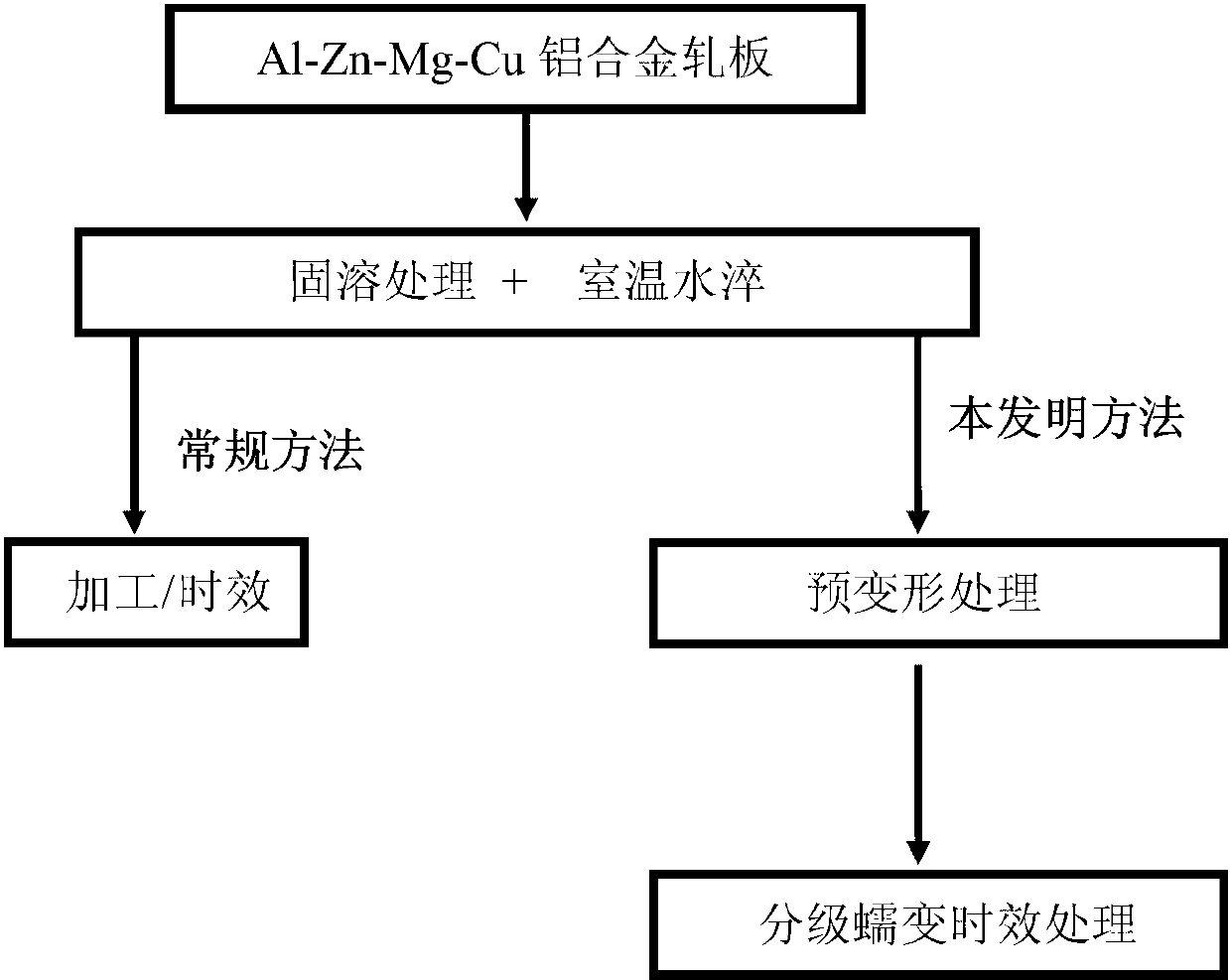

Method for multilevel creep age forming of Al-Zn-Mg-Cu series aluminium alloy plate

A creep aging forming, aluminum alloy sheet technology, applied in the field of non-ferrous metal material processing engineering, can solve the problems of high residual stress, difficult forming, etc., to improve mechanical properties and corrosion resistance, reduce production cycles, and save costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

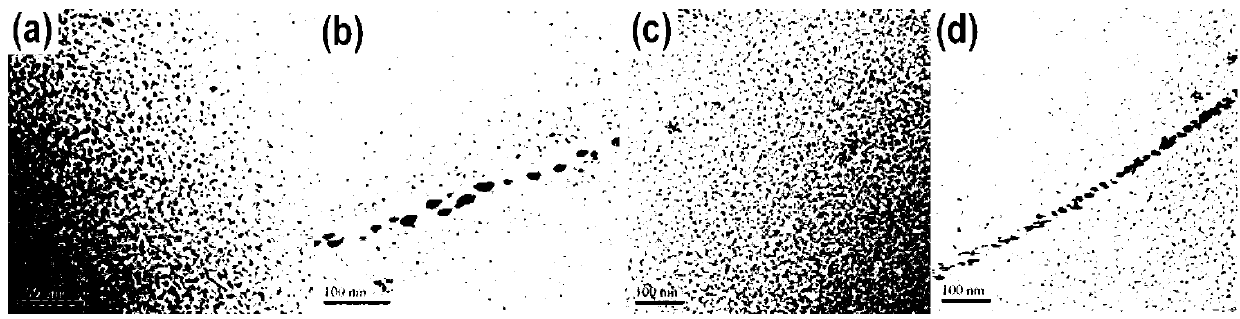

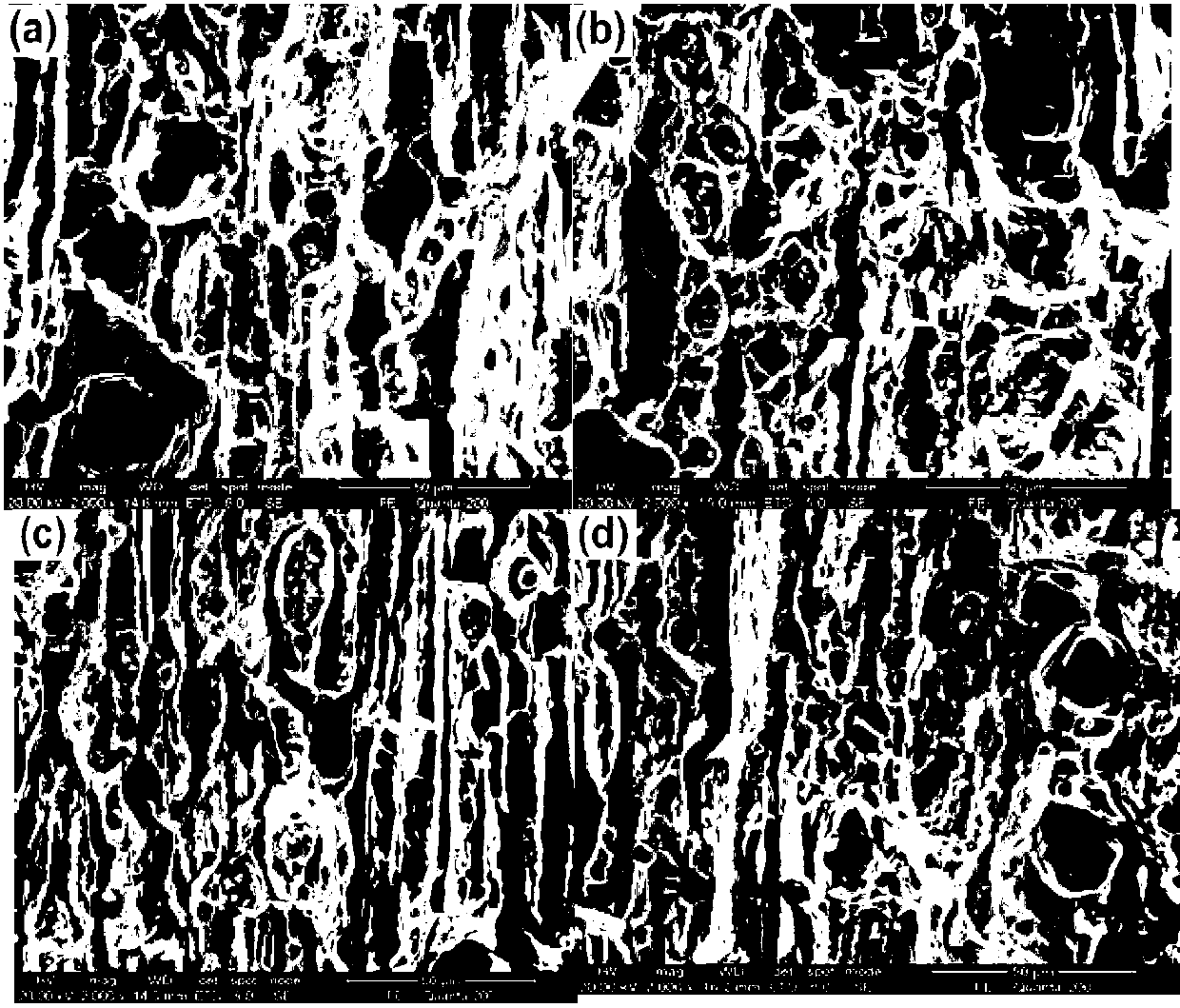

Embodiment 1

[0028] A 2mm thick plate is solidified in an air furnace at 475°C for 60 minutes and then water quenched. The creep pre-aging temperature is 120°C, the creep time is 24h, the regression temperature is 150°C, the regression time is 180min, and the re-aging is 120°C / 24h. The creep stress is 100MPa. The forming pre-bending radius is 1500mm.

Embodiment 2

[0030] B 10mm thick plate adopts 475°C air furnace for solid solution for 60 minutes and then water quenching. After quenching, the plate is pre-stretched by 2%. The creep pre-aging temperature is 120°C, the creep time is 24h, the return temperature is 150°C, and the return time 240min, then aging at 120℃ / 24h. The creep stress is 150MPa. The forming pre-bending radius is 1000mm.

Embodiment 3

[0032] The C20mm thick plate is quenched by water in an air furnace at 475°C for 60 minutes. After quenching, the plate is subjected to 4% pre-compression treatment. The creep pre-aging temperature is 120°C, the creep time is 24h, the regression temperature is 150°C, and the regression time is 180min. Re-aging at 120°C / 24h. The creep stress is 120MPa. The forming pre-bending radius is 1300mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| creep stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com