Determination method for ablation residue ratio of heat-insulating material

A heat insulation material and measurement method technology, applied in the direction of weighing by removing certain components, can solve the problems of pressure curve fluctuations, failure to reflect the amount of erosion residue of heat insulation materials or heat insulation layers, and affect the maneuverability of missiles. The method is simple, the control stability is high, and the detection data is accurate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

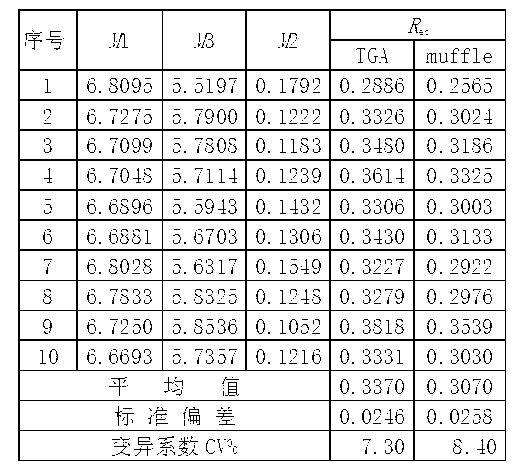

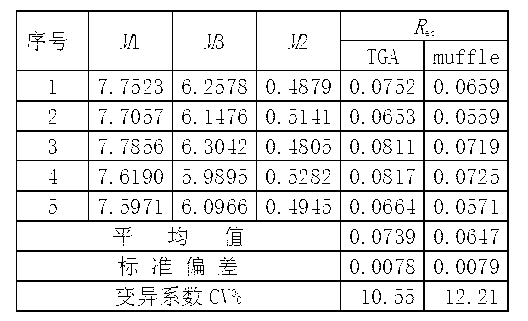

[0014] The invention will be further described below in conjunction with three specific embodiments. One case of nitrile rubber insulation layer, EPDM rubber insulation layer and silicone rubber insulation layer was selected to test the ablation residue rate. The specific operation steps and test methods are as follows.

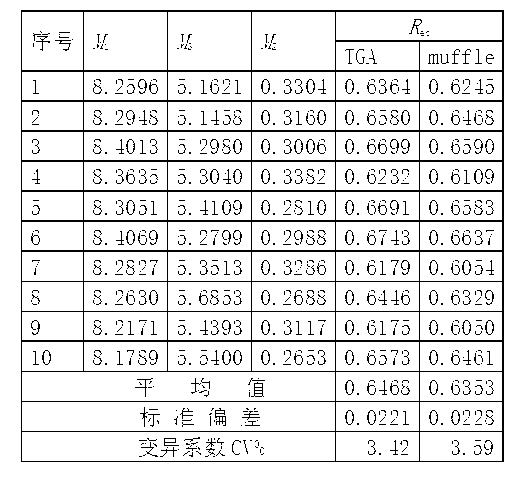

[0015] The first item is the determination of the ablation residue rate of the nitrile rubber insulation layer.

[0016] Step 1, the production, pretreatment and initial quality marking of the test piece before ablation: Take the nitrile rubber insulation material and mold it into a film and ablation piece respectively, let it stand at room temperature for one day, put it in a clean enamel plate, and put it in a 50- Remove volatiles and moisture in an oven at 80°C, weigh the initial mass of the ablation piece before ablation, and mark it as the initial mass before ablation M 1 .

[0017] Step 2. Determination and marking of the carbon residual rate of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com