Cu-containing high-strength corrosion-resistant Al-Mg-Si alloy and preparation method thereof

An alloy and corrosion-resistant technology, applied in the field of Cu-containing high-strength corrosion-resistant Al-Mg-Si alloy and its preparation, can solve problems such as unfavorable corrosion resistance of Al-Mg-Si alloy, improve mechanical properties and optimize process parameters , the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

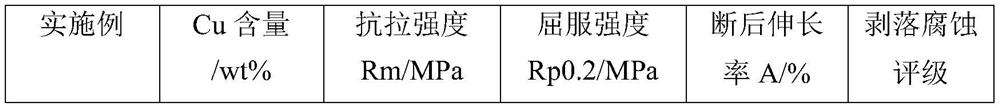

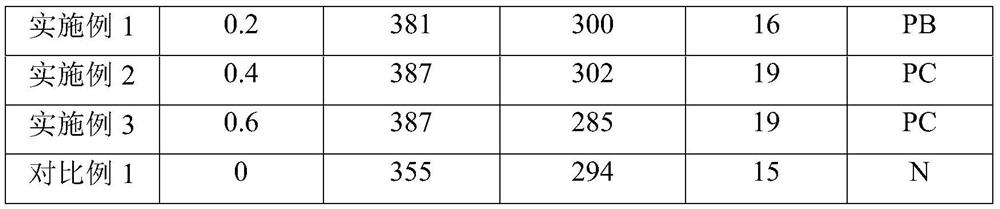

Embodiment 1

[0023] A low-content Cu alloy ingot was prepared. The mass fraction of each alloy element was Mg, 0.9%; Si, 1.5%; Cu, 0.2%; Mn, 0.4%; Er, 0.15%; Aluminum alloy ingots are cut and milled. The ingot is subjected to two-stage homogenization heat treatment. The two-stage homogenization process is: the first stage is kept at 300 °C for 8-12 hours; the second stage is kept at 535 °C for 12 hours. After the ingot undergoes homogenization heat treatment, it is then subjected to hot rolling deformation with 85% of the total deformation at a homogenization temperature of 535° C., and air-cooled to room temperature. The hot-deformed alloy was solution treated at 545°C for 30 minutes, water quenched, and aged at 155°C for 10 hours. Further preferably, the solution treatment at 545 °C for 30 min is immediately followed by water quenching, and then the alloy is immediately aged at 155 °C for 10 h.

[0024] The sheet of Example 1 was processed into a tensile specimen along the rolling dire...

Embodiment 2

[0026] A medium-content Cu alloy ingot was prepared. The mass fraction of each alloy element was Mg, 0.9%; Si, 1.5%; Cu, 0.4%; Mn, 0.4%; Er, 0.15%; Zr, 0.15%, and the balance was Al, which The steps are the same as in Example 1, and the tensile test results are listed in 1.

Embodiment 3

[0028] A high-content Cu alloy ingot was prepared. The mass fraction of each alloy element was Mg, 0.9%; Si, 1.5%; Cu, 0.6%; Mn, 0.4%; Er, 0.15%; The steps are the same as in Example 1, and the tensile test results are listed in 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com