Method for enhancing anti-corrosion property of 700 MPa strength level high-alloying 7000 series aluminum alloy

A technology of alloying and aluminum alloy, which is applied in the field of aluminum alloy technology, can solve problems such as the difficulty in balancing strength and corrosion resistance, and the unsatisfactory comprehensive performance of high-alloyed 7000 series aluminum alloys, etc., to achieve good engineering value and application prospects, equipment The effect of low requirements and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

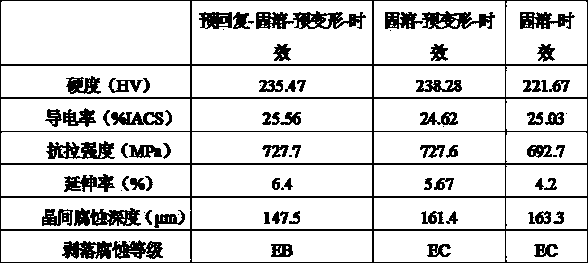

[0019] The high-alloyed 7000 series aluminum alloy extruded material with the measured mass fraction of Al-10.78Zn-2.78Mg-2.59Cu-0.22Zr-0.047Sr is subjected to 250±5℃×24h+300±5℃×6h+350 Pre-recovery annealing at ±5°C×6h+400±5°C×6h, 450±5°C×2h+460±5°C×2h+470±5°C×2h after heat preservation, room temperature water quenching and solution treatment, 2% plastic deformation Pre-deformation, 121±5℃×24h aging treatment. Its hardness, electrical conductivity, strength, intergranular corrosion, and exfoliation corrosion properties were measured, and compared with the alloy without pre-recovery annealing and pre-deformation.

[0020] The experimental results are as follows:

[0021]

Embodiment 2

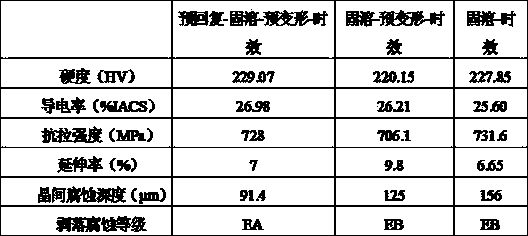

[0023] The high-alloyed 7000 series aluminum alloy extruded material with the measured mass fraction of Al-11.54Zn-3.51Mg-2.26Cu- 0.24Zr-0.0025Sr was subjected to 250±5℃×24h+300±5℃×6h+350 Pre-recovery annealing at ±5°C×6h+400±5°C×6h, 450±5°C×2h+460±5°C×2h+470±5°C×2h after heat preservation, room temperature water quenching and solution treatment, 2% plastic deformation Pre-deformation, 121±5℃×24h aging treatment. Its hardness, electrical conductivity, strength, intergranular corrosion, and exfoliation corrosion properties were measured, and compared with the alloy without pre-recovery annealing and pre-deformation.

[0024] The experimental results are as follows:

[0025]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com