High-strength high-toughness corrosion-resistant Al-Cu-Mg aluminum alloy

An al-cu-mg, aluminum alloy technology, applied in the field of new high-strength and high-toughness Al-Cu-Mg aluminum alloy, can solve the problems of poor comprehensive performance, poor fracture toughness, poor toughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following examples are intended to further illustrate the present invention, rather than limit the present invention.

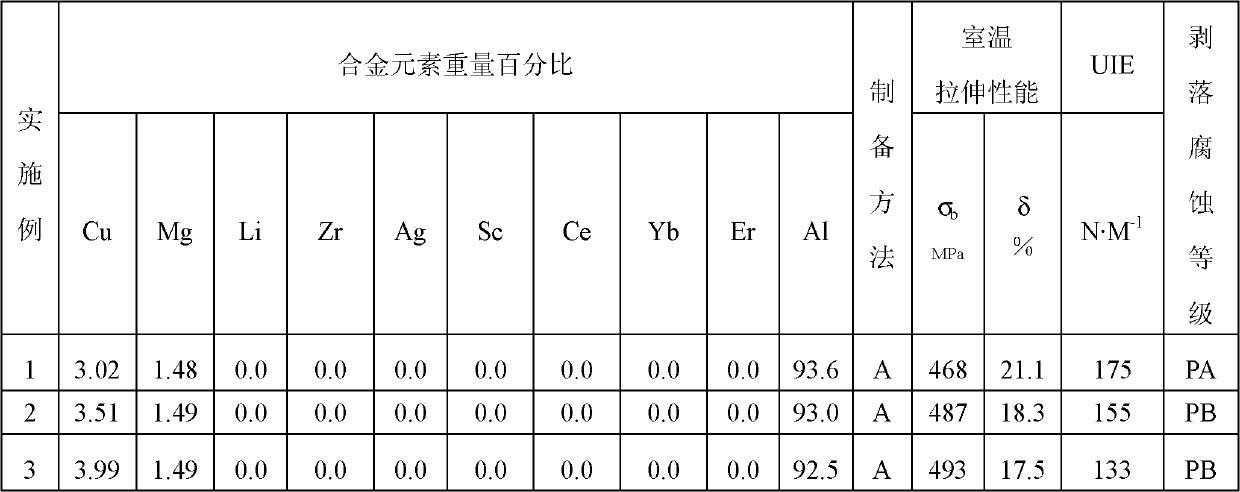

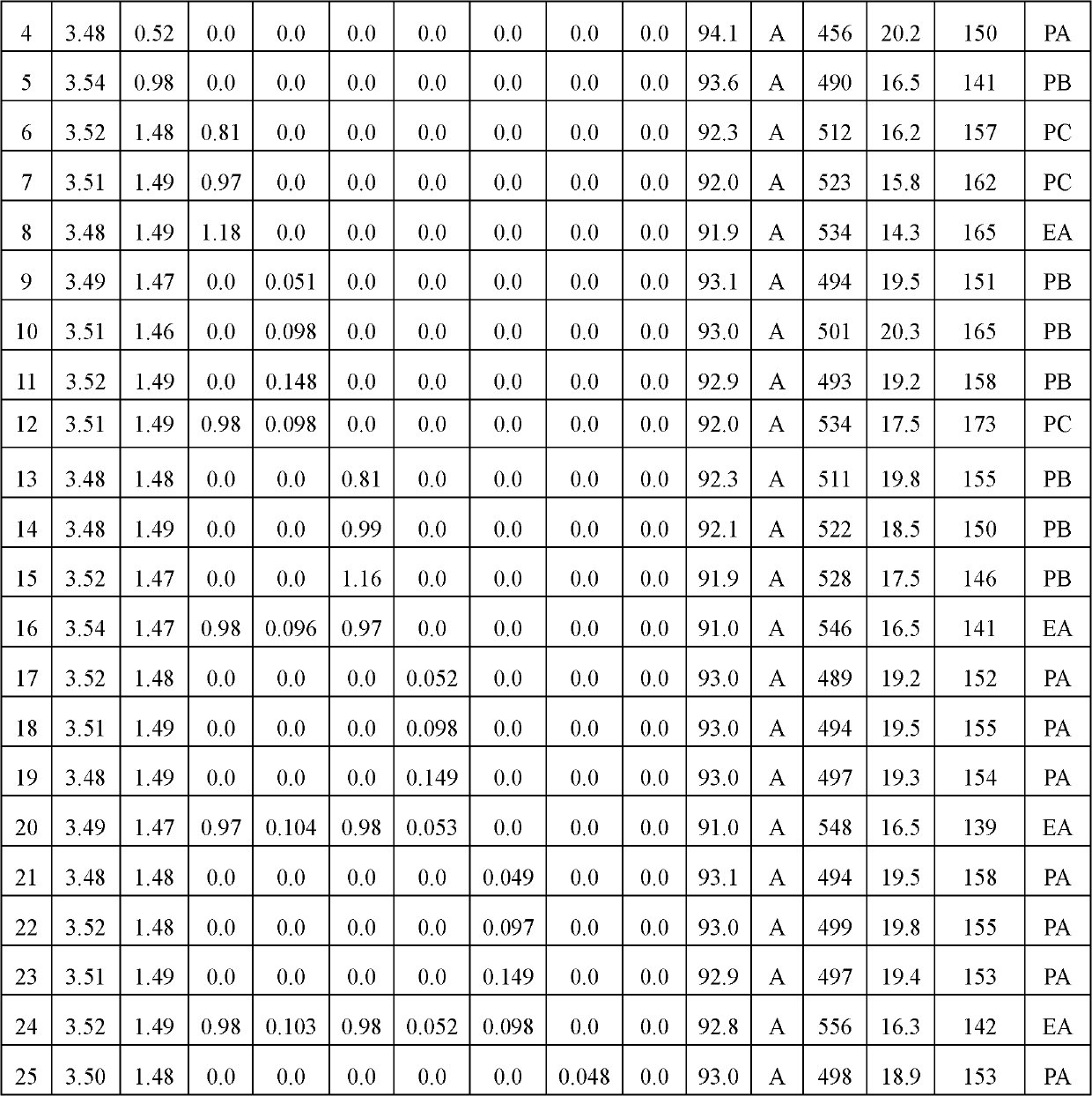

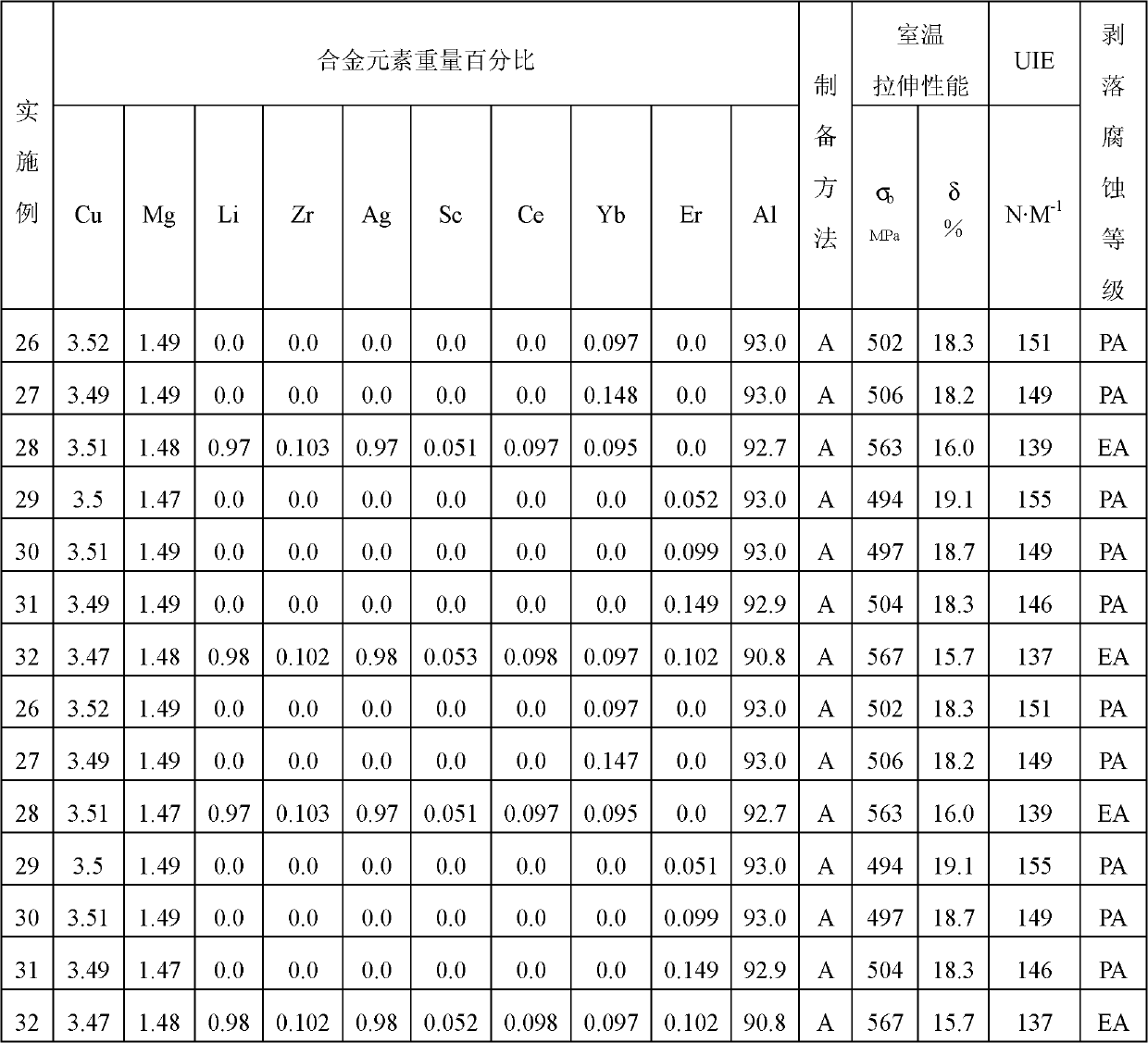

[0025] In each embodiment, the mass fraction of impurities Si is less than 0.2%, Fe is less than 0.25%, the alloy element Zn is less than 0.2%, Ti is less than 0.06%, and Mn is less than 1.2%. Table 1, Table 2, Table 3, and Table 4 show the weight percent content of alloying elements, preparation methods, room temperature tensile properties, toughness, and corrosion resistance of the examples.

[0026] Table 1

[0027]

[0028]

[0029] Table 2

[0030]

[0031] table 3

[0032]

[0033] Table 4

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com