Bioactive scaffold for controlling multistage release of drugs and manufacturing method of bioactive scaffold

A bioactive, porous scaffold technology, applied in the fields of manufacturing tools, additive manufacturing, tissue regeneration, etc., can solve the problems that small and short bone defects are not suitable, cannot use liquid drugs, and is difficult to cooperate with application, etc., to promote the self-healing of bone injury. , The effect of promoting bone self-healing and excellent self-healing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

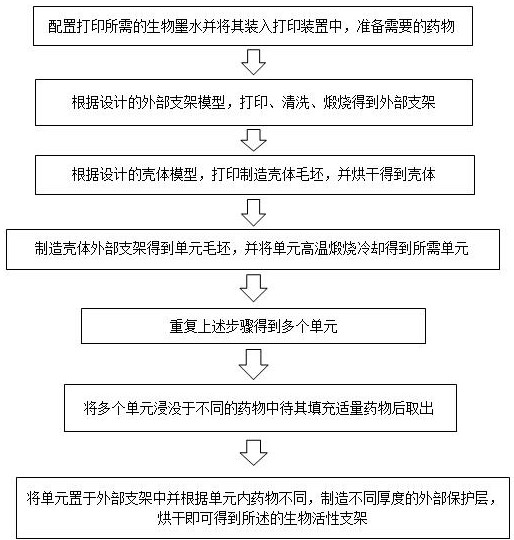

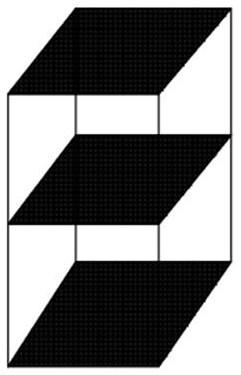

[0057] The bioactive stent for controlling the multi-stage release of drugs manufactured in this embodiment, for the selected materials, the outer stent, the inner unit and the outer stent protective layer adopt hydroxyapatite, and the drug loading in the inner unit is bisphosphonate and alprostadil , see the specific process figure 1 .

[0058] 1) Mix the required hydroxyapatite powder with the hydrogel solution at a ratio of 3:2 to obtain a high-viscosity bioink.

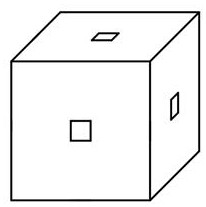

[0059] 2) The bio-ink is added to the 3D printer, and the external support model is designed. Considering the shrinkage after sintering, the cross-section of the frame is a square of 10mm, and the thickness between the units is 1mm. Use a 3D printer to manufacture the outer bracket, and get the outer bracket blank, clean the outer bracket blank, and then dry it in an oven at 80 degrees Celsius for 6 hours, put the outer bracket in a high-temperature furnace for high-temperature calcination, and burn it at 1200 de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com