Thermal spraying device for short shaft part

A thermal spraying, short-axis technology, applied in coating, fusion spraying, metal material coating process and other directions, can solve the problem of inconvenient use of thermal spraying devices and protective devices, and achieve simple combined use, convenient handling, and safe protection. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Now in conjunction with accompanying drawing, the present invention will be further described.

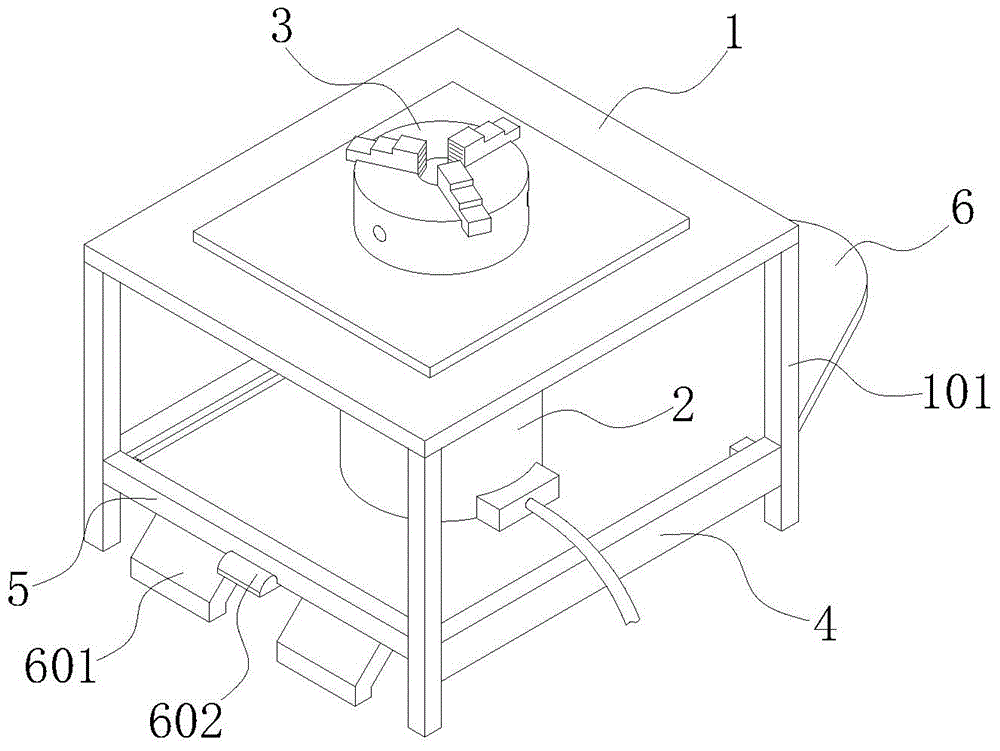

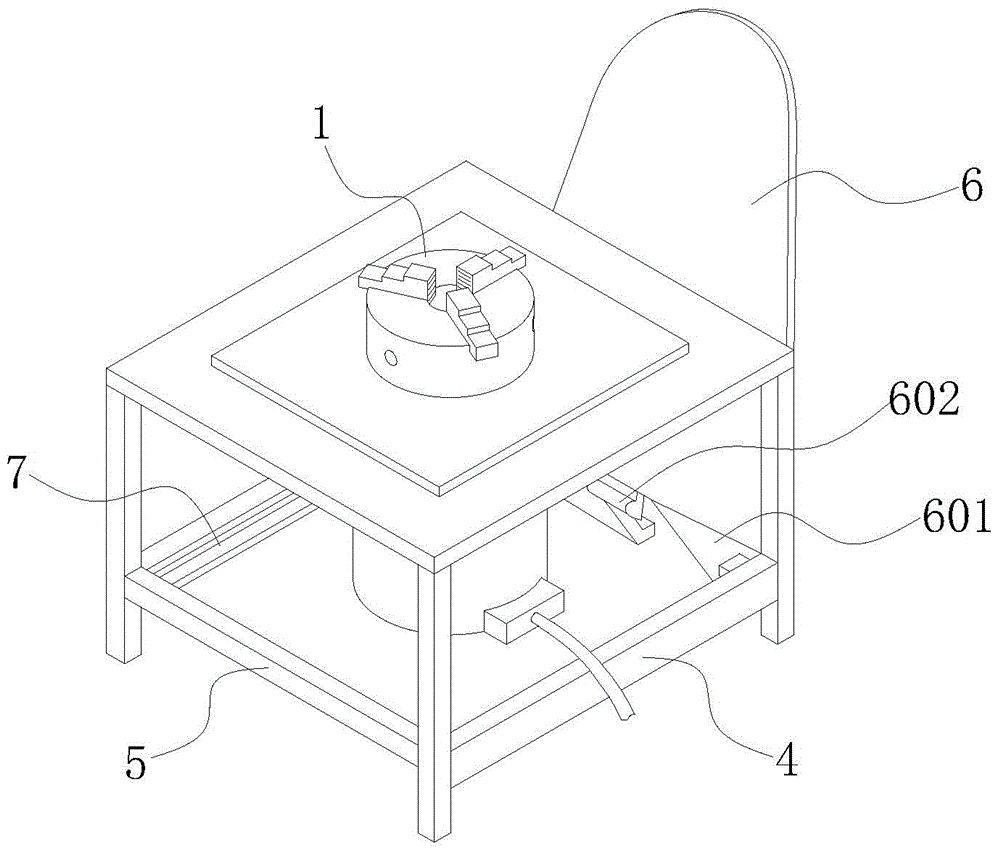

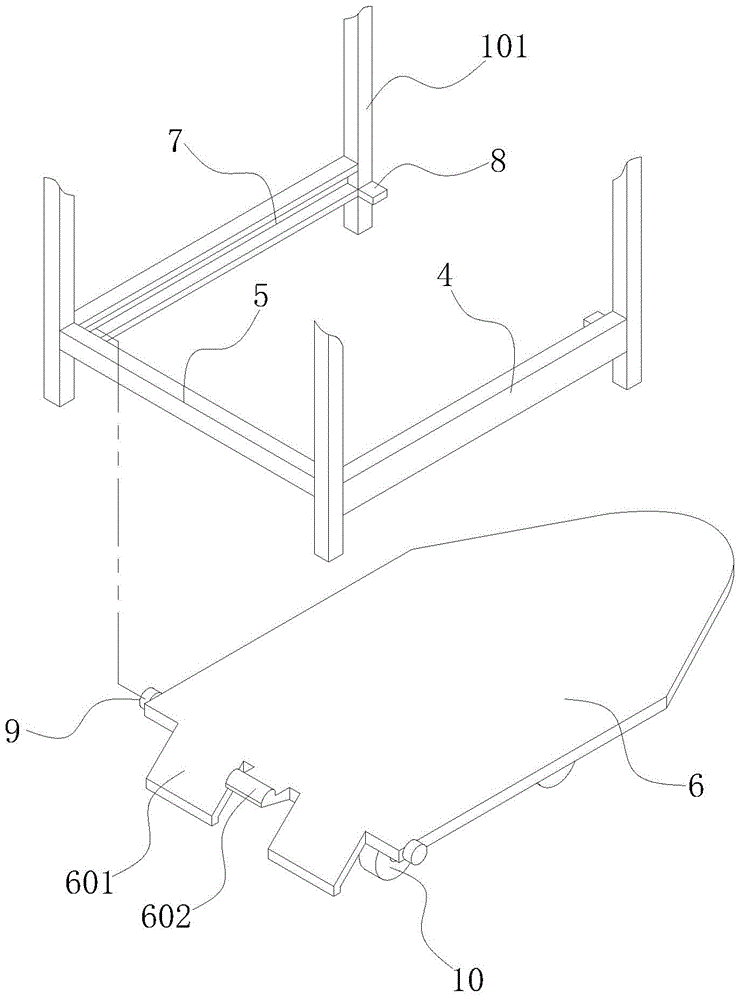

[0024] Such as figure 1 , figure 2 As shown, the short-axis thermal spraying device includes a frame 1, a motor 2, a three-jaw chuck 3, and a protective plate 6. The top surface of the frame 1 is the working surface, and the lower part of the working surface is fixedly connected to the motor 2 through a bracket, and the output of the motor 2 is The shaft passes through the working surface and is connected with the three-jaw chuck 3 through a transmission member. The lower part of the frame 1 is a supporting member 101. The supporting member 101 includes four supporting legs, and two mutually parallel guiding bars 4 and a limiting bar 5 for limiting are formed between the supporting legs. One end of the protective plate 6 is provided with a supporting foot 601 which is inclined with respect to the surface of the protective plate 6 . The two sides of the protective plate 6 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com