A self-healing light-controlled plastic polyurethane elastomer material, its preparation and application

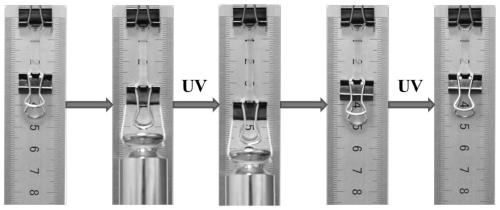

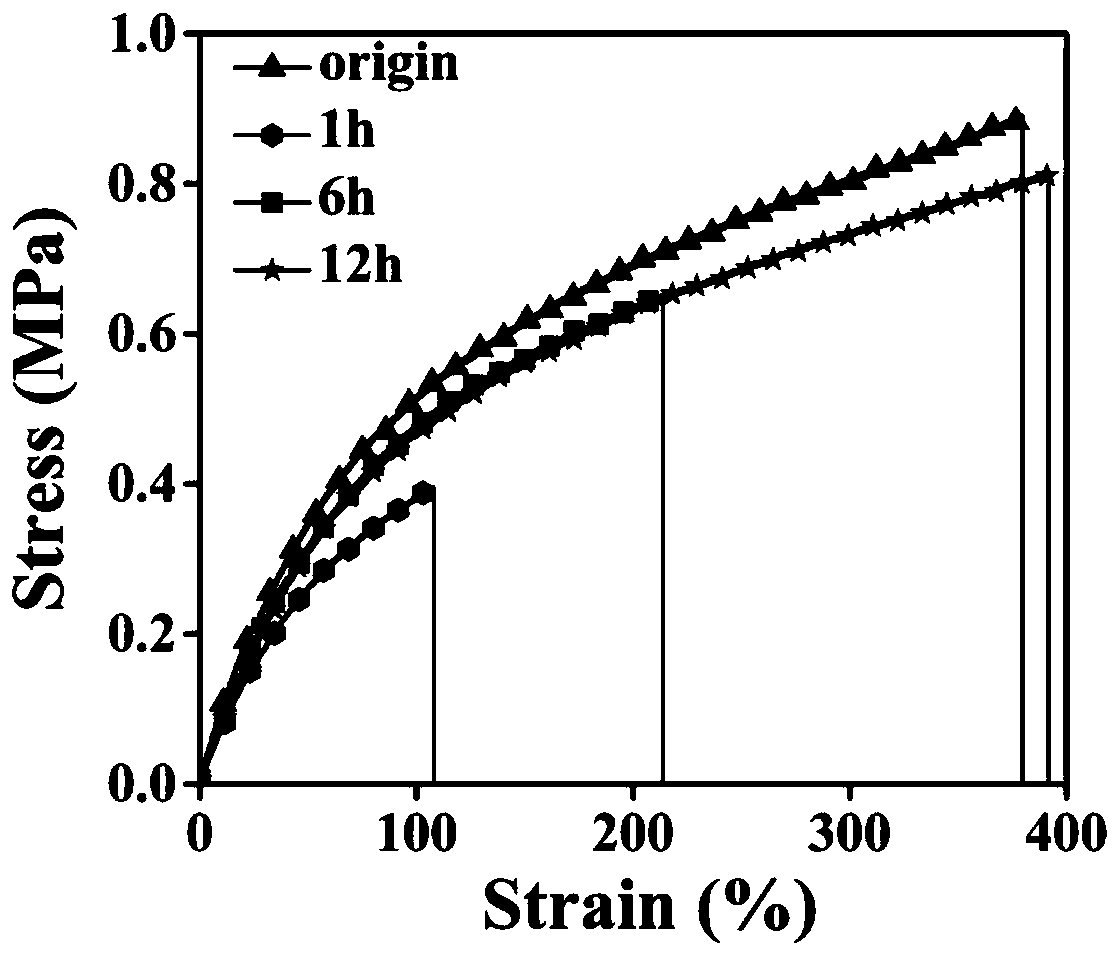

A polyurethane elastomer and elastomer material technology, applied in the field of flexible intelligent drive materials, can solve problems such as slow response to external stimuli and complex structural design, and achieve excellent self-healing effect, simple pre-treatment, and short healing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The invention provides a kind of preparation method of described polyurethane elastomer material, comprises the steps:

[0049] (1) Under light-shielding conditions and under the protection of inert gas nitrogen, the organic solution of the oligomer diol, tetrahydroxyl functionalized hexaaryl biimidazole molecules, catalyst and polyhydric alcohol after drying treatment are mixed and stirred to obtain Mixed solution; drying treatment The specific steps are: vacuum-dry the oligomer diol at 70-90° C. for 1 to 3 hours. The organic solvent used in the organic solution is anhydrous tetrahydrofuran (THF), and the catalyst is dibutyltin dilaurate (DBTDL). The purpose of drying the oligomer diol is to remove the moisture therein, so as to avoid the reaction between water molecules and diisocyanate, resulting in that the polyurethane elastomer material of the present invention cannot be obtained. The purpose of inert gas protection is to avoid the participation of oxygen in the ...

Embodiment 1

[0059] Using PTMG as oligomer diol, 2-Cl-4-diol-HABI molecular switch and glycerol as crosslinking agent were used to synthesize double crosslinked self-healing light-controlled plastic polyurethane elastic material. The molecular structure of 2-Cl-4-diol-HABI is as follows.

[0060]

[0061] Weigh PTMG (1.9g; 1.9mmol) into a round bottom flask, vacuum-dry at 70°C for about 1h, and cool to room temperature under the protection of nitrogen atmosphere. Then weigh glycerol (42mg; 0.456mmol) and inject it into the above round bottom flask, then weigh 2-Cl-4-diol-HABI (128mg; 0.152mmol), dissolve it with 10ml anhydrous THF, mix it with PTMG, and add Stir the catalyst DBTDL vigorously for half an hour; extract 0.33ml of HDI with a 1ml syringe and add it to the above mixed solution; vacuumize the mixed solution three to four times, stir for about ten minutes, then spin steam, completely remove THF, and pour into the mold . Put it into a vacuum drying oven, react under vacuum con...

Embodiment 2

[0063] Using PTMG as oligomer diol, 2-Cl-4-diol-HABI molecular switch and glycerol as crosslinking agent were used to synthesize double crosslinked self-healing light-controlled plastic polyurethane elastic material.

[0064] Weigh PTMG (3.8g; 3.8mmol) into a round bottom flask, vacuum-dry at 70°C for about 1h, and cool to room temperature under the protection of nitrogen atmosphere. Then weigh glycerol (112mg; 1.216mmol) and inject it into the above round bottom flask, then weigh 2-Cl-4-diol-HABI (128mg; 0.152mmol), dissolve it with 10ml anhydrous THF, mix it with PTMG, and add Stir the catalyst DBTDL vigorously for half an hour; extract 0.66ml of HDI with a 1ml syringe and add it to the above mixed solution; vacuumize the mixed solution three to four times, stir for about ten minutes, then spin steam to remove THF completely, and pour it into the mold . Put it into a vacuum drying oven, react under vacuum conditions at 45°C for 24h, cool to room temperature and take it out....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com