Self-repairing wear-resistant coating and preparation method thereof

A wear-resistant coating and self-healing technology, applied in the coating and other directions, can solve the problems such as the inability to meet the wear resistance requirements of the coating, the inability to delay the coating damage, and the unsatisfactory wear resistance, so as to improve the speed and effect of self-healing. The effect of improving self-healing speed and excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

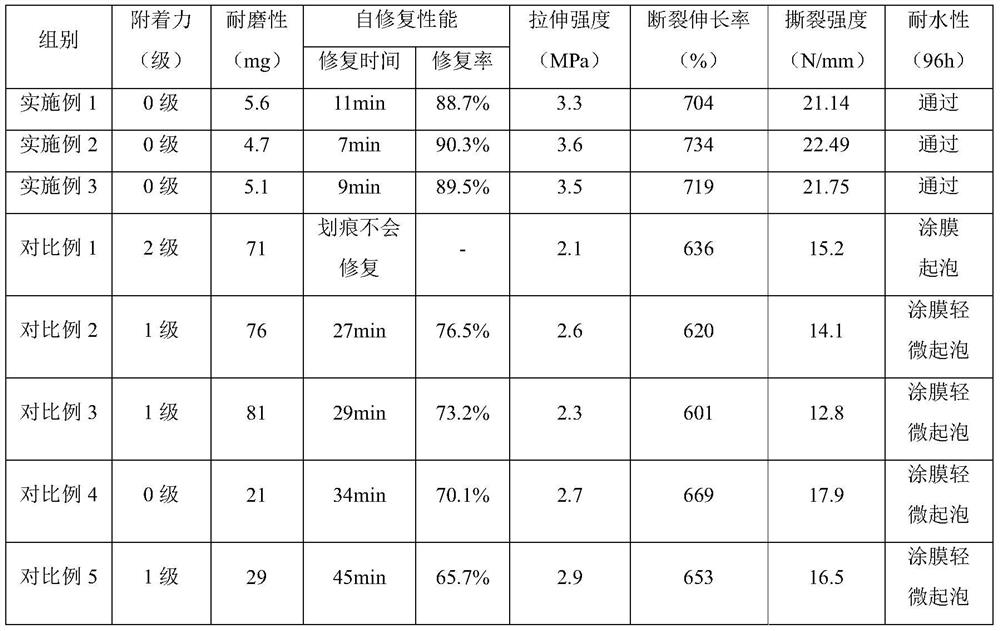

Examples

Embodiment 1

[0033] A self-repairing wear-resistant coating, the preparation method comprising the following steps: weighing 50 parts of polyvinyl acetal modified phenolic resin, 20 parts of calcium naphthenate, 10 parts of methyltrimethoxysilane, latent curing Mix 8 parts of agent and 50 parts of solvent evenly, add 15 parts of self-repairing microcapsules, 3 parts of film-forming agent, and 3 parts of defoamer to it, and stir evenly to obtain self-repairing wear-resistant coating;

[0034] Self-healing microcapsules are prepared by the following steps:

[0035] (1) Dissolve ethyl cellulose and dibutyltin dilaurate in deionized water, heat to 60°C, and stir evenly to obtain an ethyl cellulose solution;

[0036] Wherein, the mass ratio of ethyl cellulose, dibutyltin dilaurate, and deionized water is 1:2.5:3.

[0037] (2) mix polyvinyl acetal modified phenolic resin and emulsifier evenly to obtain emulsion;

[0038] (3) Add the emulsified solution dropwise into the ethyl cellulose solutio...

Embodiment 2

[0041] A self-repairing wear-resistant coating, the preparation method comprising the following steps: weighing 75 parts of polyvinyl acetal modified phenolic resin, 15 parts of calcium naphthenate, 15 parts of methyltrimethoxysilane, latent curing 12 parts of solvent and 60 parts of solvent are mixed uniformly, 22 parts of self-repairing microcapsules, 5 parts of film-forming agent and 5 parts of defoamer are added thereto, and stirred evenly to obtain self-repairing wear-resistant coating;

[0042] Self-healing microcapsules are prepared by the following steps:

[0043] (1) Dissolve ethyl cellulose and dibutyltin dilaurate in deionized water, heat to 65°C, and stir evenly to obtain an ethyl cellulose solution;

[0044] Wherein, the mass ratio of ethyl cellulose, dibutyltin dilaurate, and deionized water is 2:2:4.

[0045] (2) mix polyvinyl acetal modified phenolic resin and emulsifier evenly to obtain emulsion;

[0046] (3) Add the emulsified solution dropwise into the eth...

Embodiment 3

[0049] A self-repairing wear-resistant coating, the preparation method comprising the following steps: weighing 100 parts of polyvinyl acetal modified phenolic resin, 10 parts of calcium naphthenate, 20 parts of methyltrimethoxysilane, latent curing Mix 15 parts of agent and 50 parts of solvent evenly, add 30 parts of self-repairing microcapsules, 8 parts of film-forming agent, and 2 parts of defoamer to it, and stir evenly to obtain self-repairing wear-resistant coating;

[0050] Self-healing microcapsules are prepared by the following steps:

[0051] (1) Dissolve ethyl cellulose and dibutyltin dilaurate in deionized water, heat to 70°C, and stir evenly to obtain an ethyl cellulose solution;

[0052] Wherein, the mass ratio of ethyl cellulose, dibutyltin dilaurate, and deionized water is 1.5:3:5.

[0053] (2) mix polyvinyl acetal modified phenolic resin and emulsifier evenly to obtain emulsion;

[0054] (3) Add the emulsified solution dropwise into the ethyl cellulose solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com