Hot-melt pressure-sensitive adhesive and preparation method thereof

A hot-melt pressure-sensitive adhesive and molten material technology, used in adhesives, adhesive additives, polymer adhesive additives, etc. problem, to achieve the effect of good adhesion, improved high temperature resistance and improved wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

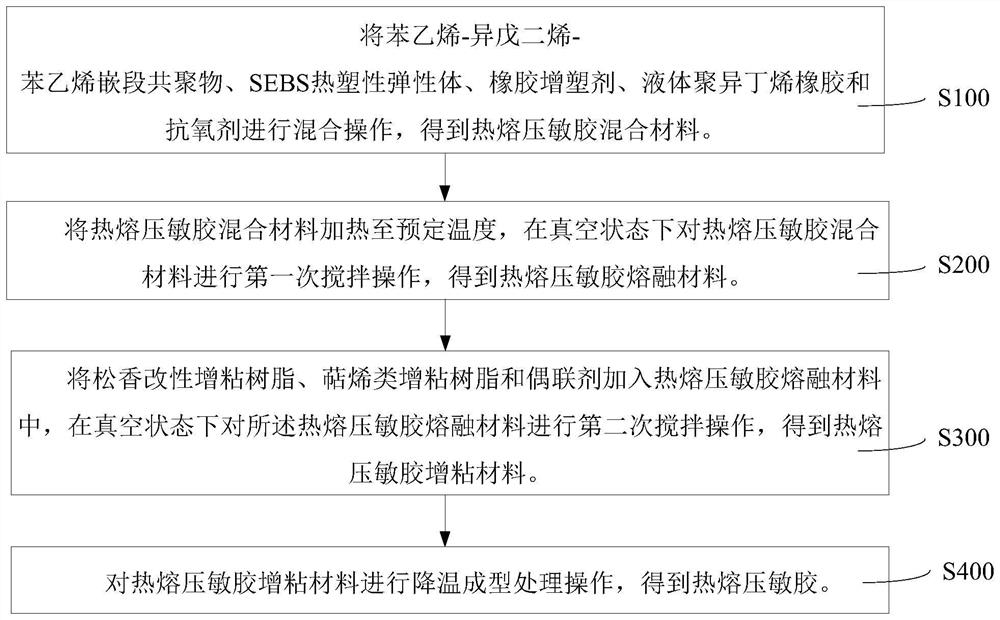

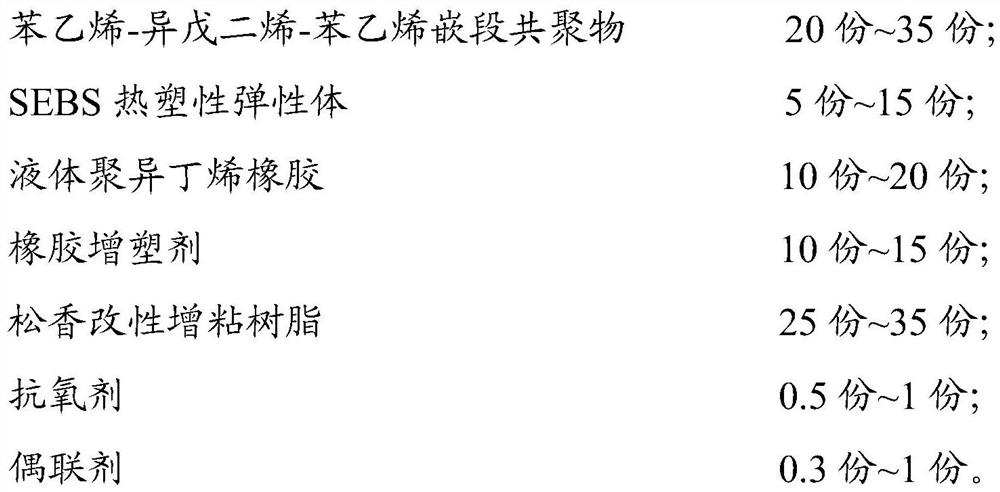

[0045] In order to better understand the hot-melt pressure-sensitive adhesive of the present invention, the present application also provides a preparation method of the hot-melt pressure-sensitive adhesive. The preparation method of the above-mentioned hot-melt pressure-sensitive adhesive comprises the following steps: mixing styrene-isoprene-styrene block copolymer, SEBS thermoplastic elastomer, rubber plasticizer, liquid polyisobutylene rubber and antioxidant operation to obtain a hot-melt pressure-sensitive adhesive mixed material; heat the hot-melt pressure-sensitive adhesive mixed material to a predetermined temperature, and perform the first stirring operation on the hot-melt pressure-sensitive adhesive mixed material in a vacuum state to obtain a hot-melt pressure-sensitive adhesive mixed material Pressure-sensitive adhesive melting material; adding rosin modified tackifying resin, terpene tackifying resin and coupling agent into the hot-melt pressure-sensitive adhesive...

Embodiment 1

[0055] Weigh respectively 200 g of styrene-isoprene-styrene block copolymer, 50 g of hydrogenated styrene-butadiene block copolymer, 10 g of naphthenic oil, 100 g of liquid polyisobutylene rubber and tetrakis [β-(3, 5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester 5g, the styrene-isoprene-styrene block copolymer, hydrogenated styrene-butadiene block copolymerization material, naphthenic oil, liquid polyisobutylene rubber and tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate]pentaerythritol ester are added to the container for mixing, and then the above mixture is poured into the reaction Heating in the kettle, slowly heating to 140° C. and then starting to stir, stirring in a vacuum state until all the materials are melted, and then continuing the reaction to stabilize for 5 minutes. Then add 250g rosin modified tackifying resin, 100g polymerized terpene resin, 50g terpene styrene resin and 3g amine coupling agent, and stir while adding, and stir i...

Embodiment 2

[0057] Weigh respectively 350g of styrene-isoprene-styrene block copolymer, 150g of hydrogenated styrene-butadiene block copolymer, 150g of paraffin oil, 200g of liquid polyisobutylene rubber and tris[2.4-di-tert-butyl Phenyl] phosphite 10g, the styrene-isoprene-styrene block copolymer, hydrogenated styrene-butadiene block copolymer, paraffin oil, liquid polyisobutylene rubber and three [ 2. Add 4-di-tert-butylphenyl] phosphite into the container for mixing, then pour the above mixture into the reaction kettle for heating, slowly heat to 170°C and start stirring, and stir under vacuum until all the materials are melted , continue the reaction to stabilize for 20 minutes. Then add 350g rosin modified tackifying resin, 150g polymerized terpene resin, 100g terpene phenolic resin and 10g epoxy coupling agent, and stir while adding, and stir in a vacuum state for 60 minutes. After stirring, the melted hot-melt pressure-sensitive adhesive is cooled to obtain a molded hot-melt press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com