Method for preparing anti-aging, anti-corrosion and anti-fouling lubricating oil

A lubricating oil and anti-aging technology, applied in the field of lubricating oil, can solve the problems of poor anti-fouling performance, poor anti-aging and anti-corrosion performance, etc., to improve the anti-aging and anti-corrosion performance, prolong the anti-fouling period, and improve the anti-corrosion and anti-fouling performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

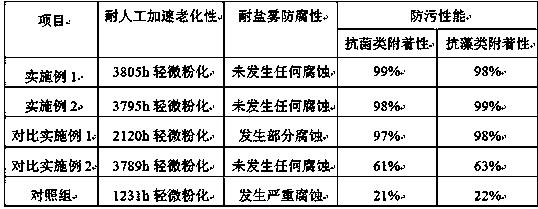

Examples

Embodiment 1

[0027] A method for preparing anti-aging anti-corrosion anti-fouling lubricating oil, characterized in that it comprises the following steps, the following raw materials are by weight:

[0028] (1) Compound modification of hydrotalcite:

[0029] Dissolve 0.2 parts of polyaspartic acid in 200 parts of buffer solution with a pH of 8, add 2 parts of sodium stearate organically modified hydrotalcite, ultrasonically disperse for 5 minutes, then magnetically stir for 30 minutes, centrifuge, wash 3 times, and then disperse In 80 parts of cerium nitrate aqueous solution, ultrasonically dispersed for 5 minutes, then magnetically stirred for 1 hour, centrifuged and washed 3 times with water to obtain cerium ion-sodium stearate compound modified hydrotalcite;

[0030] Among them, the preparation of organically modified hydrotalcite with sodium stearate: add deionized water and 0.12 part of sodium stearate to 2 parts of hydrotalcite at a ratio of 1:5, heat in a water bath to 80°C and stir...

Embodiment 2

[0041] A method for preparing anti-aging anti-corrosion anti-fouling lubricating oil, characterized in that it comprises the following steps, the following raw materials are by weight:

[0042] (1) Compound modification of hydrotalcite:

[0043] Dissolve 0.3 parts of polyaspartic acid in 300 parts of a buffer solution with a pH of 9, add 3 parts of sodium stearate organically modified hydrotalcite, ultrasonically disperse for 10 minutes, then magnetically stir for 40 minutes, centrifuge, wash 5 times, and then disperse In 120 parts of cerium nitrate aqueous solution, ultrasonically dispersed for 10 minutes, then magnetically stirred for 2 hours, centrifuged and washed 5 times with water to obtain cerium ion-sodium stearate compound modified hydrotalcite;

[0044] Among them, the preparation of organically modified hydrotalcite with sodium stearate: add deionized water and 0.18 part of sodium stearate to 3 parts of hydrotalcite at a ratio of 1:5, heat in a water bath to 85°C an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wear scar diameter | aaaaa | aaaaa |

| Wear scar diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com