Self-repairing conductive hydrogel material and preparation method thereof

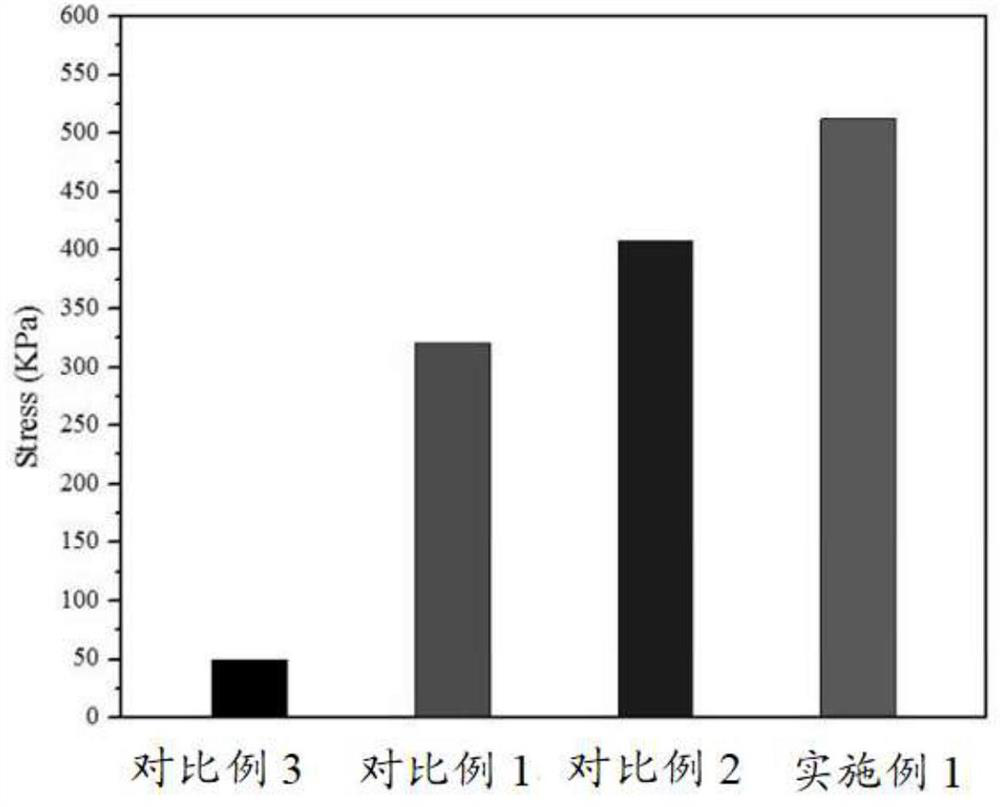

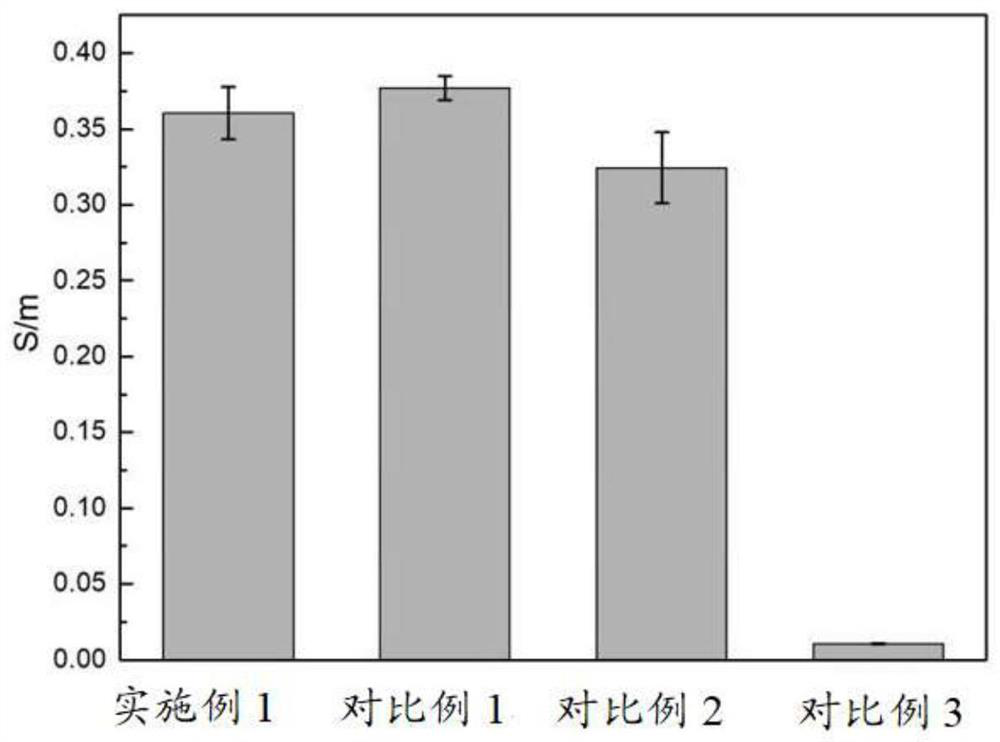

A conductive hydrogel, self-healing technology, applied in the field of hydrogel materials, can solve the problems of insufficient mechanical strength, insoluble conductive fillers in water, poor self-healing performance, etc. Repair performance, enhance the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The main idea of the embodiment of the present invention is: a preparation method of a self-healing conductive hydrogel material, comprising the following steps:

[0033] 1) adding pyrogallic acid into the dissolved borate solution, adding polypyrrole powder after stirring, and stirring until uniformly dispersed to obtain a mixed solution;

[0034] 2) Mix the mixed liquid with acrylamide monomer, cross-linking agent, and tetramethylethylenediamine, stir fully to dissolve them all, and obtain a reaction system, and then add glycerin and an initiator to the reaction system, And placed at room temperature to form a gel.

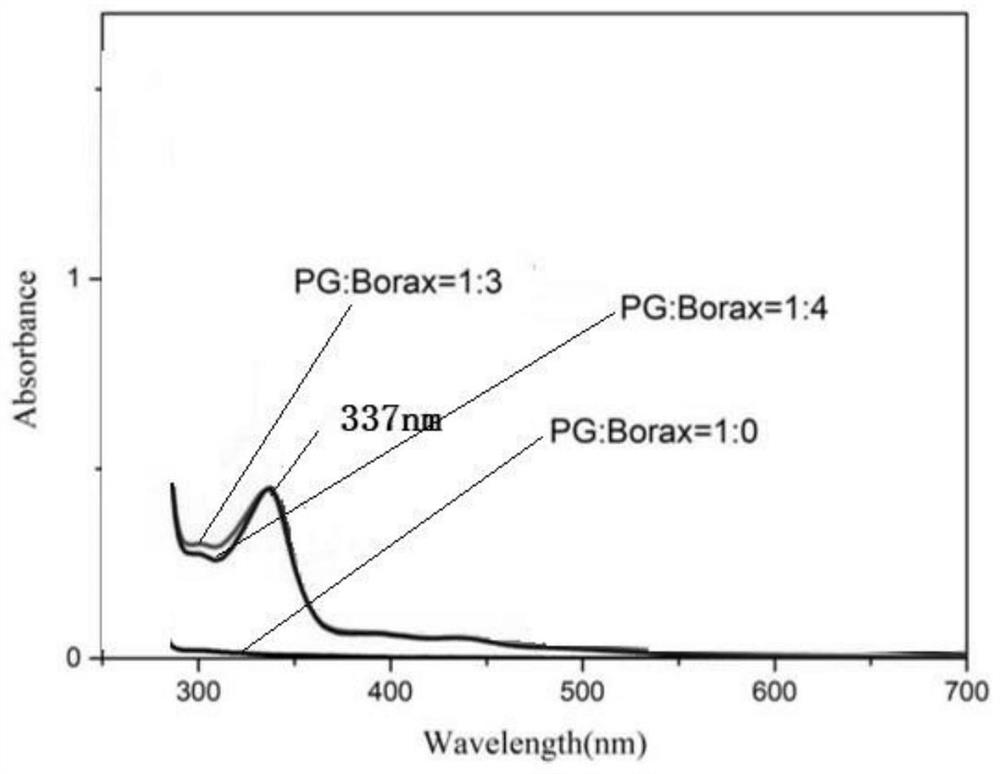

[0035] Among them, the compound selected to achieve self-healing in the embodiment of the present invention is pyrogallic acid, which has three hydroxyl groups. The dopamine-like substances produced after oxidation provide more cross-linking points. Make the gel bond more tightly after self-healing, and the reaction is shown in the following formula: ...

Embodiment 1

[0040] (1) Dissolve 0.192g of sodium tetraborate into 16ml of distilled water first, add 0.040g of pyrogallic acid to the solution after it is completely dissolved, and stir for 15 minutes so that pyrogallic acid and sodium tetraborate fully react, use Sodium tetraborate protects the pyrogallic acid. This reaction is a reversible reaction, which can reduce the oxidation rate of pyrogallic acid.

[0041]

[0042](2) Add 0.04 g of carbon black-doped polypyrrole powder (the mass ratio of carbon black to polypyrrole is 4:1) to the above mixture of pyrogallic acid and sodium tetraborate, stir well for 30 seconds to disperse uniform. The carbon black-doped polypyrrole powder of this embodiment is purchased from Sigma-ALDRICH (Sigma-ALDRICH) company, proportioning is the carbon black of the polypyrrole (PPy) of 20% mass ratio and 80% mass ratio, CAS number: 30604 -81-0).

[0043] (3) Transfer the mixture prepared in (2) to an ice-water bath, add 4g of acrylamide monomer, 0.016g...

Embodiment 2

[0046] (1) Dissolve 0.3g of sodium tetraborate into 16ml of distilled water first, add 0.070g of pyrogallic acid to the solution after it is completely dissolved, and stir for 30 minutes to make pyrogallic acid and sodium tetraborate fully react, use Sodium tetraborate protects the pyrogallic acid. This reaction is a reversible reaction, which can reduce the oxidation rate of pyrogallic acid.

[0047] (2) Add 0.08 g of carbon black-doped polypyrrole powder (the mass ratio of carbon black to polypyrrole is 4:1) to the above mixture of pyrogallic acid and sodium tetraborate, and stir for 40 seconds to disperse uniform.

[0048] (3) Transfer the mixture prepared in (2) to an ice-water bath, add 4g of acrylamide monomer, 0.025g of N,N-methylenebisacrylamide, and 100μl of tetramethyl Ethylenediamine was stirred thoroughly to dissolve it all. Afterwards, 1.0 ml of glycerin and 0.80 g of ammonium persulfate were added, and then the mixed solution was transferred out and placed at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com