Environmental-friendly soundproof waterproof concrete wall brick and preparation method thereof

A waterproof concrete and sound insulation technology, applied in the field of building materials, can solve the problems of limited waterproof performance and complex components of concrete, and achieve the effect of good sound insulation effect, simple operation and sufficient raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

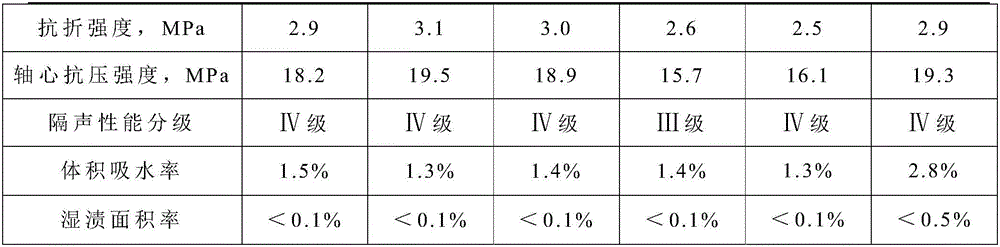

Examples

Embodiment 1

[0030] An environment-friendly, sound-insulating and waterproof concrete wall brick, the preparation method of which comprises the following steps:

[0031] 1) The construction waste is crushed, sorted, screened, shaped, cleaned, and dried to obtain recycled coarse and fine aggregates, wherein the particle size of the recycled coarse aggregate is 5-30mm, and the particle size of the recycled fine aggregate is 0-5mm;

[0032] 2) Mix 60 parts of cement, 35 parts of recycled coarse aggregate, 10 parts of ceramsite, 20 parts of recycled fine aggregate, 5 parts of bamboo fiber, 2 parts of silica sol, 0.5 parts of water reducing agent, and 20 parts of water, and mix well ,spare;

[0033] Among them, bamboo fiber is obtained by bleaching with hydrogen peroxide and drying naturally, with a tensile strength greater than 120MPa, a length of 10-20mm, an equivalent diameter of 2-3mm, and a water content of 8%-10%; ceramsite is made by adding cement to waste cinders. The non-burning garba...

Embodiment 2

[0041] An environment-friendly, sound-insulating and waterproof concrete wall brick, the preparation method of which comprises the following steps:

[0042] 1) The construction waste is crushed, sorted, screened, shaped, cleaned, and dried to obtain recycled coarse and fine aggregates, wherein the particle size of the recycled coarse aggregate is 5-30mm, and the particle size of the recycled fine aggregate is 0-5mm;

[0043] 2) Mix 70 parts of cement, 40 parts of recycled coarse aggregate, 15 parts of ceramsite, 28 parts of recycled fine aggregate, 6 parts of bamboo fiber, 3 parts of silica sol, 0.5 parts of water reducing agent, and 36 parts of water, and mix well ,spare;

[0044] Among them, bamboo fiber is obtained by bleaching with hydrogen peroxide and drying naturally, with a tensile strength greater than 120MPa, a length of 10-20mm, an equivalent diameter of 2-3mm, and a water content of 8%-10%; ceramsite is made by adding cement to waste cinders. The non-burning garba...

Embodiment 3

[0052] An environment-friendly, sound-insulating and waterproof concrete wall brick, the preparation method of which comprises the following steps:

[0053] 1) The construction waste is crushed, sorted, screened, shaped, cleaned, and dried to obtain recycled coarse and fine aggregates, wherein the particle size of the recycled coarse aggregate is 5-30mm, and the particle size of the recycled fine aggregate is 0-5mm;

[0054] 2) Mix 80 parts of cement, 50 parts of recycled coarse aggregate, 20 parts of ceramsite, 35 parts of recycled fine aggregate, 8 parts of bamboo fiber, 5 parts of silica sol, 1 part of water reducing agent, and 50 parts of water, and mix well ,spare;

[0055] Among them, bamboo fiber is obtained by bleaching with hydrogen peroxide and drying naturally, with a tensile strength greater than 120MPa, a length of 10-20mm, an equivalent diameter of 2-3mm, and a water content of 8%-10%; ceramsite is made by adding cement to waste cinders. The non-burning garbage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com