Self-repairing waterborne polyurethane coating containing imine bonds

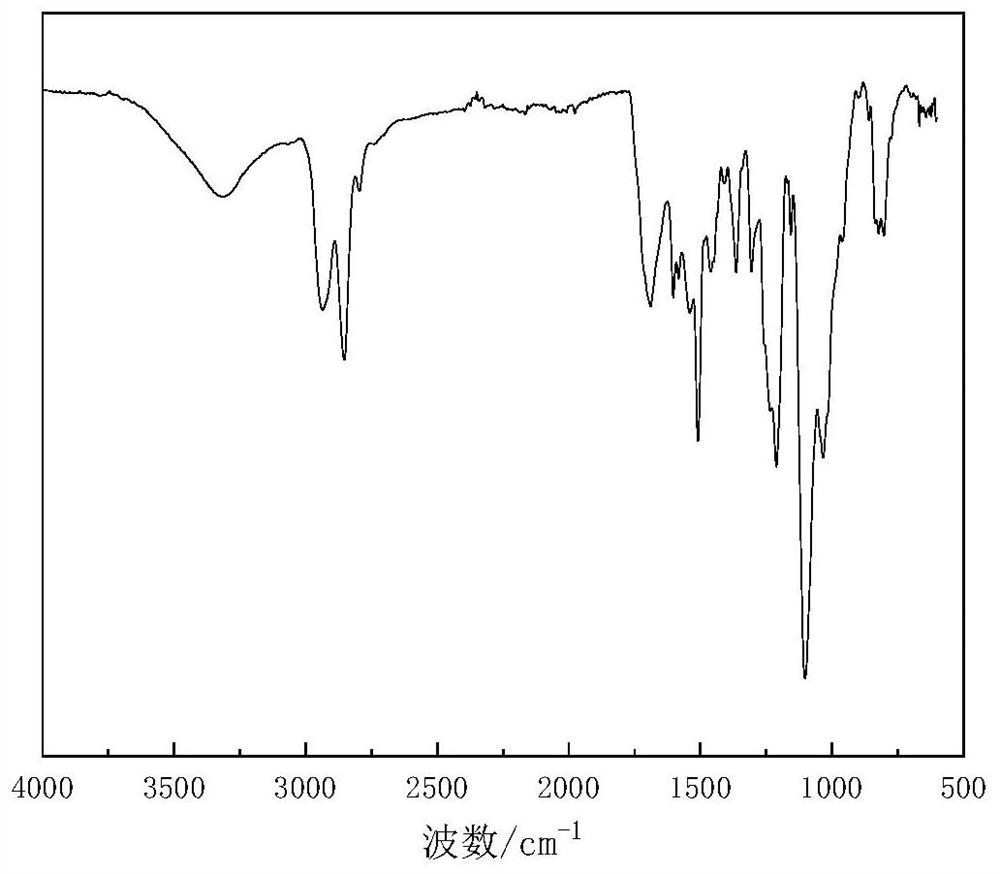

A water-based polyurethane, imine bond technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problem of low repair rate of self-healing materials, and achieve the effects of excellent self-healing effect, strong mechanical properties, and simple and rapid response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of self-healing waterborne polyurethane coating containing imine bond, its preparation method comprises the steps:

[0031] (1) Preparation of polyurethane chain extender containing imine bond

[0032] Add 10g of p-phenylenediamine and 150ml of absolute ethanol into a 500ml three-neck flask and heat until completely dissolved to obtain mixture B, dissolve 12g of p-hydroxybenzaldehyde in 150ml of absolute ethanol to obtain mixture A, add 1.2ml of acetic acid to mixture A The mixture C was obtained as a catalyst, and the mixture C was slowly dropped into the mixture B, stirred with a magnetic force, and heated to 100° C. for 5 hours in an oil bath under reflux. The resulting reaction system was cooled at room temperature, and a large amount of light yellow crystals were precipitated, filtered under reduced pressure, rinsed with absolute ethanol for 3 to 4 times, the filter cake was taken out, and dried in vacuum to obtain compound C—p-phenylenediamine p-hydroxybenz...

Embodiment 1

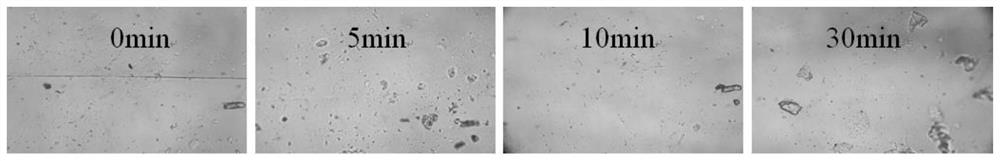

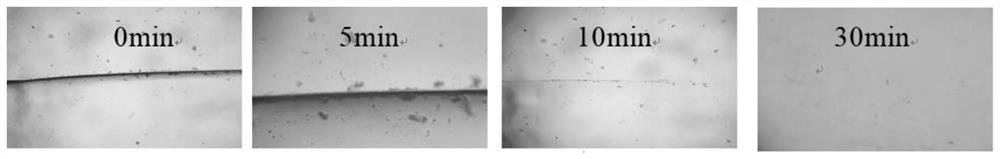

[0042] The tensile strength of the coating film obtained in Example 1 is 31.94MPa, the elongation at break is 1154.2, and the scratches disappear completely after being repaired at 60°C for 5 minutes. figure 2 , After being completely cut off, after repairing at 80°C for 2 hours, the tensile strength of the coating film was 31.70MPa, the elongation at break was 1039.0, and the self-healing rate was 99.2%.

[0043] After the obtained coating film is crushed, the result obtained is as follows: Figure 4 , after 100°C, 10min, 5MPa heat treatment in a hot press, it becomes a smooth and complete coating film again. Figure 5 .

Embodiment 2

[0045] A kind of self-healing waterborne polyurethane coating containing imine bond, its preparation method comprises the steps:

[0046] (1) Preparation of polyurethane chain extender containing imine bond

[0047] Add 10g of o-phenylenediamine and 150ml of absolute ethanol into a 500ml three-neck flask and heat until completely dissolved to obtain mixture B, dissolve 12g of salicylaldehyde in 150ml of absolute ethanol to obtain mixture A, add 1.2ml of acetic acid to mixture A as a catalyst to obtain Mixture C, slowly drop mixture C into mixture B, stir magnetically, heat to 100° C. and reflux for 5 h in an oil bath. The obtained reaction system was cooled at room temperature, and a large amount of pale yellow crystals were precipitated, filtered under reduced pressure, rinsed with absolute ethanol for 3 to 4 times, the filter cake was taken out, and dried in vacuum to obtain compound C—o-phenylenediamine salicylaldehyde bis-Schiff base.

[0048] (2) Preparation of waterborn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com