Soil-resistant structure and automobile component provided with said soil-resistant structure

A structure and antifouling technology, applied in the field of auto parts, can solve the problems of decreased water resistance, insufficient use of waterproof materials, low affinity between fine porous layers and waterproof materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

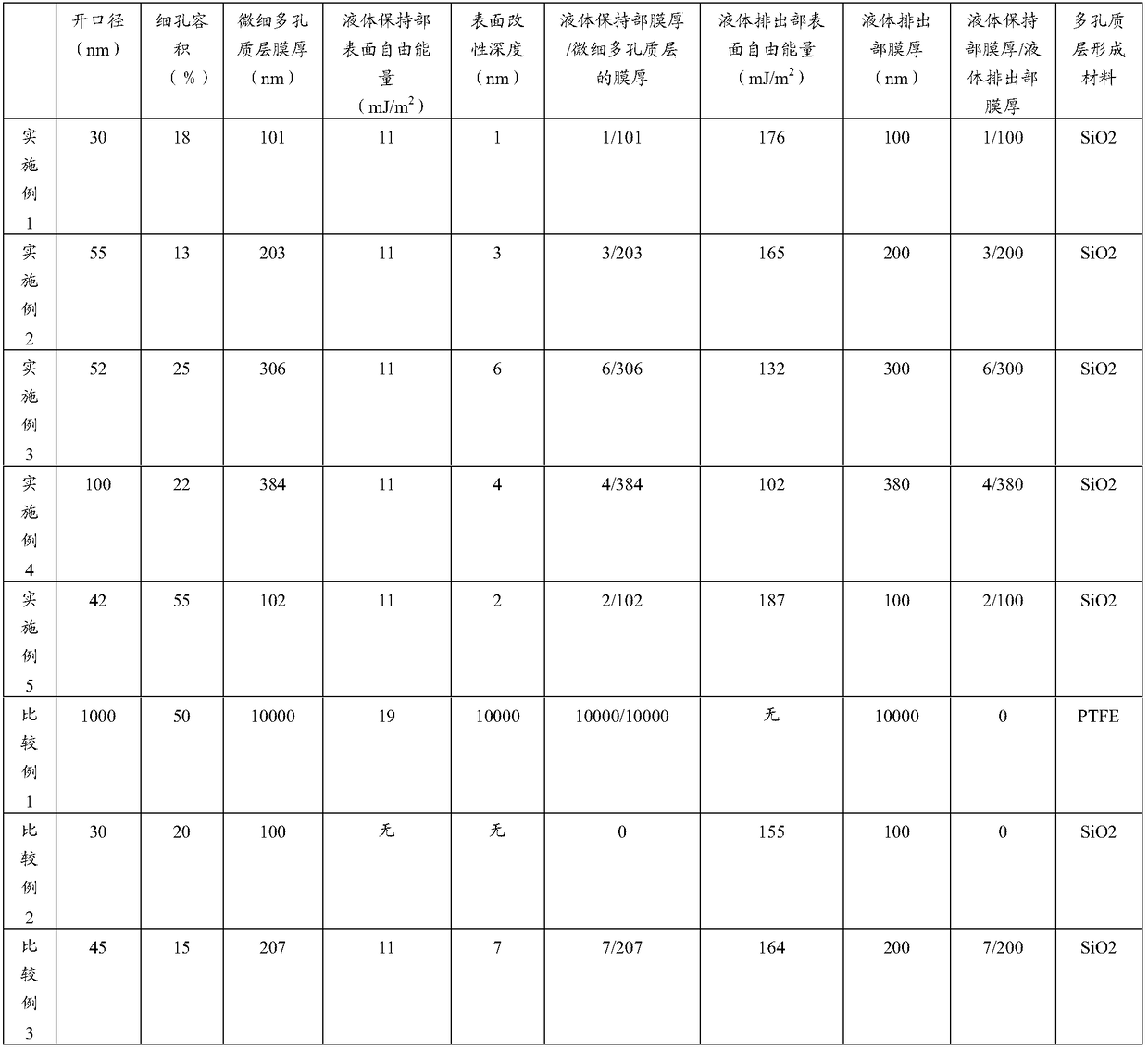

Embodiment 1

[0098] (Preparation of coating liquid)

[0099] 50 mmol of water, 11 mmol of triethylene glycol, and 13 mmol of isopropanol were uniformly mixed, and 0.2 g of 32N sulfuric acid was added to prepare a solution A.

[0100] Next, solution B was prepared by mixing 54 mmol of tetraethoxysilane and 13 mmol of isopropanol.

[0101] The above-mentioned solution A and the above-mentioned solution B were mixed, stirred by a stirrer for 15 minutes, and a sol was prepared. This sol solution was diluted 5 times with ethanol to prepare a coating solution.

[0102] (coating)

[0103] The above coating solution was applied on soda lime glass by the spin coating method (rotation speed: 2000 rpm, rotation time: 20 seconds, humidity 60%).

[0104] (temporary sintering)

[0105] Within 1 minute after coating, the coated glass plate was put into an oven heated to 150° C. to dry for 1 hour, then placed in the oven, cooled to room temperature (25° C.) and temporarily cured.

[0106] (sintering)...

Embodiment 2

[0113] An antifouling structure was produced in the same manner as in Example 1 except that the condition of spin coating was changed to rotation speed: 1500 rpm.

Embodiment 3

[0115]An antifouling structure was produced in the same manner as in Example 1 except that the condition of spin coating was changed to rotation speed: 700 rpm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com