Cold-rolled steel sheet for precise household appliance welded pipe and production method thereof

A technology of cold-rolled steel plate and production method, which is applied in the field of cold-rolled steel plate for precision home appliance welded pipe and its production field, and can solve problems such as unfavorable high-speed cold-drawn diameter reduction production, reduced processing efficiency, and excessively high yield strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

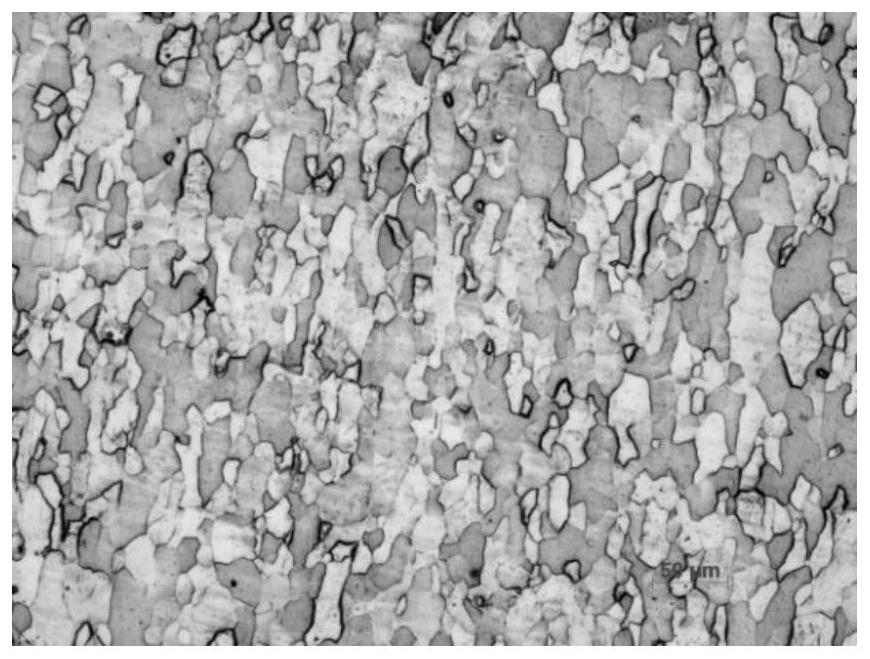

Image

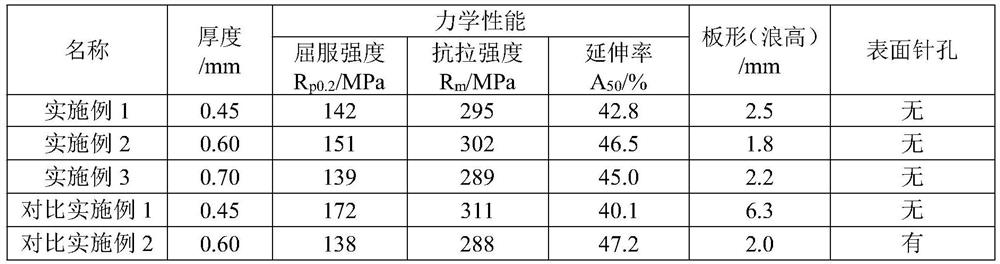

Examples

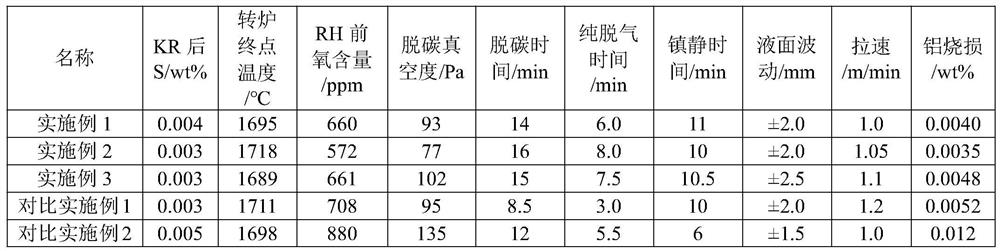

Embodiment 1

[0031] The mass percentages of the chemical composition of the cold-rolled steel plate for precision home appliance welded pipe are: C=0.0031wt%, Mn=0.16wt%, Si=0.005wt%, P=0.010wt%, S=0.007wt%, Als=0.038wt% , N=0.0033wt%, Ti=0.063wt%, and the balance is Fe and other residual trace elements.

[0032] The production method of Example 1 is as follows: the S content after KR desulfurization in the steelmaking process is 0.004wt%, the end point temperature of the converter is 1695°C, the oxygen content before the RH refining treatment is 660ppm, the RH decarburization vacuum degree is 93Pa, the decarburization time is 14min, and the pure degassing time is 6min, sedation time 11min, continuous casting liquid level fluctuation ≤ ± 2mm, pouring at a constant casting speed of 1.0m / min, RH to the casting machine aluminum burning loss of 0.0040wt%, the depth of peeling the head blank is 5.0mm. The slab is red delivered in the hot rolling process, the slab exit temperature is 1245°C, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com