Long-term self-healing asphalt concrete based on stress-responsive multi-chamber capsules

An asphalt concrete, self-healing technology, applied in the field of materials, can solve the problems of potholes, micro-cracks, and easy aging of asphalt pavement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Dissolve 75g of sodium alginate in 3000ml of water at 50°C to form a sodium alginate solution with a concentration of 2.5%. After the sodium alginate solution is cooled to room temperature, it is mixed with 385g of asphalt regenerant and 9.6g of Tween 80. The cutting rate is 4000 rpm, and the shearing time is 15 minutes; under the action of magnetic stirring at 60 rpm, the mixture of sodium alginate, asphalt regenerant and Tween 80 is dripped at a rate of 60 drops / min 50°C, 500g of 3% calcium chloride solution, after all the mixed solution is dropped into the calcium chloride solution, continue to stir and react at 50°C for 4 hours, wash with distilled water, and dry with forced ventilation for 24 hours to obtain a stress-responsive multi-chamber self-healing capsule , the capsule particle size is 2.1mm, and the regenerant coating rate is 67.2%.

[0024] Repeat the above preparation method, but do not add surfactant Tween 80, the shear rate is 2000 rpm, and the shear ti...

Embodiment 2

[0029] Dissolve 90g of sodium alginate in 3000ml of water at 55°C to form a sodium alginate solution with a concentration of 3%. After the sodium alginate solution is cooled to room temperature, it is mixed with 340g of asphalt regenerant and 8.8g of Tween 80. The cutting rate is 5500 rpm, and the shearing time is 10 minutes; under the action of magnetic stirring at 100 rpm, the mixture of sodium alginate, asphalt regenerant and Tween 80 is dripped at a rate of 80 drops / min 55°C, 600g of 3% calcium chloride solution, after all the mixed solution was dropped into the calcium chloride solution, continue to stir and react at 55°C for 3h, wash with distilled water, and dry with forced ventilation for 24h to obtain a stress-responsive multi-chamber capsule.

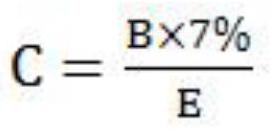

[0030] Using SMA-13 gradation, the mass percentage of each raw material is: 86.3% of coarse and fine aggregate, 8.7% of mineral powder, 5.6% of asphalt, and 0.6% of stress-responsive multi-chamber capsule (the regenerant coat...

Embodiment 3

[0032] Dissolve 90g of sodium alginate in 3000ml of water at 50°C to form a sodium alginate solution with a concentration of 3%. After the sodium alginate solution is cooled to room temperature, it is mixed with 1030g of asphalt regenerant and 25.8g of Tween 80. The cutting rate is 5000 rpm, and the shearing time is 10 minutes; under the action of magnetic stirring at 80 rpm, the mixture of sodium alginate, asphalt regenerant and Tween 80 is dripped at a rate of 100 drops / min. 50°C, 700g of 2.5% calcium chloride solution, after all the mixed solution was dropped into the calcium chloride solution, continue to stir and react at 50°C for 4h, wash with distilled water, and dry with forced ventilation for 24h to obtain a stress-responsive multi-chamber capsule.

[0033]Using Superpave-12.5 gradation, the mass percentages of each raw material are: coarse and fine aggregate 88.2%, mineral powder 6.9%, asphalt 4.9%, stress-responsive multi-chamber capsule 0.4% (capsule regeneration ag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com