Cellulose fiber internal curing-based ultra-high-performance cement-based composite material and preparation method thereof

A cellulose fiber, ultra-high-performance technology, applied in the field of building materials or basic engineering construction, to achieve the effect of optimizing the pore structure, the overall dosage is not high, and enhancing the waterproof performance and durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the above-mentioned ultra-high-performance cement-based composite material based on cellulose fiber internal maintenance comprises the following steps:

[0035] (1) Add water, fine aggregate and cellulose fiber into the mixer at a speed of 110-130 rpm, and stir for 20-35 minutes;

[0036] (2) Add cement, active mineral admixture, and high-efficiency admixture to the mixer in turn, at a speed of 55-65 rpm, and stir for 3-5 minutes until a slurry is formed;

[0037] (3) Slowly add fine steel fibers into the slurry, stir for 2 to 3 minutes at a rotation speed of 55 to 65 rpm, and then stir for 1 to 2 minutes at a rotation speed of 110 to 130 rpm;

[0038] (4) Pour the mortar into the forming mold, vibrate for 60-100 times, remove the mold after standing for 24 hours, and maintain it to obtain the ultra-high performance cement-based composite material.

Embodiment 1

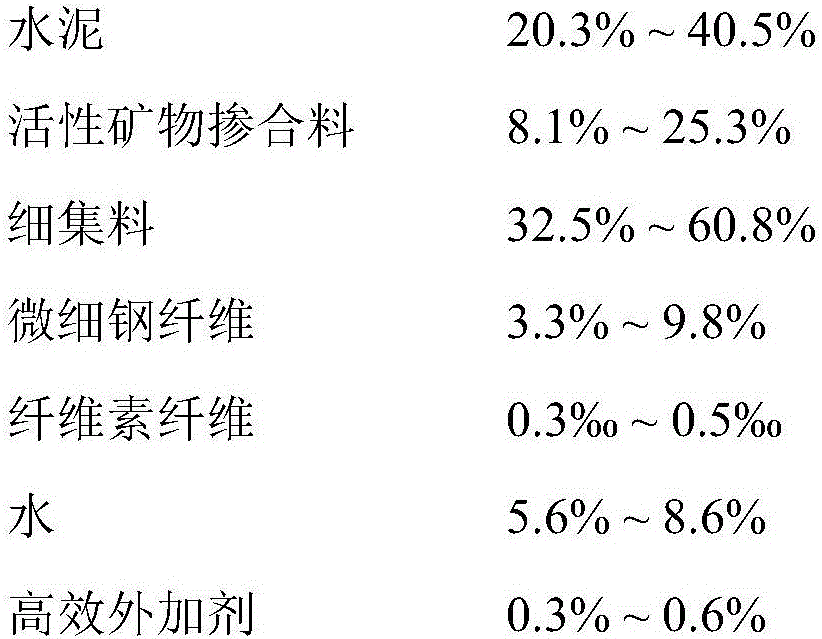

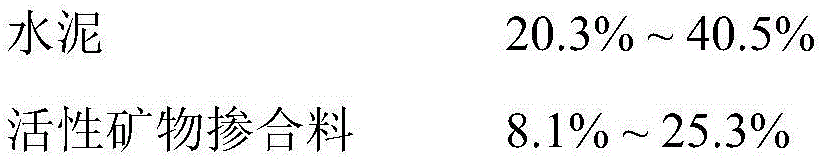

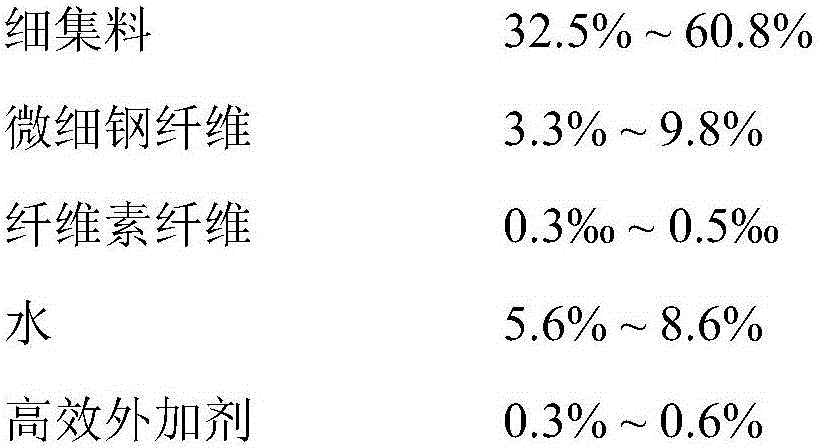

[0041]

[0042]

[0043] Among them, the cement is P·I 52.5 Portland cement; mineral admixtures include F-class fly ash 13.1%, silica fume 4.3% and light calcium powder 4.3%; River sand, continuous gradation, fineness modulus 2.6; fine steel fiber diameter 0.2mm, length 13mm, ultimate tensile strength 2850MPa; cellulose fiber monofilament diameter 18μm, average length 2.1mm, ultimate tensile strength 800MPa; The water reducing agent is a polycarboxylate water reducing agent with a water reducing rate of 40%.

[0044] The performance of the ultra-high-performance cement-based composite material prepared by the above-mentioned components according to the aforementioned process after 28 days of standard curing is as follows:

[0045] Flexural strength 47.8MPa, compressive strength 125.5MPa, self-shrinkage strain 148.9×10 -6 .

Embodiment 2

[0047]

[0048] Among them, the cement is P·I 52.5 Portland cement; mineral admixtures include metakaolin 12.0%, rice husk ash 4.0%; fine aggregate is ordinary river sand with a maximum particle size of 2.50mm, continuous gradation, Modulus 2.4; fine steel fiber diameter 0.25mm, length 12mm, ultimate tensile strength 2380MPa; cellulose fiber monofilament diameter 10μm, average length 1.8mm, ultimate tensile strength 900MPa; high-efficiency admixture is water reducing rate of 40% Polycarboxylate water reducer.

[0049] The performance of the ultra-high-performance cement-based composite material prepared by the above-mentioned components according to the aforementioned process after 28 days of standard curing is as follows:

[0050] Flexural strength 46.7MPa, compressive strength 128.4MPa, self-shrinkage strain 130×10 -6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Ultimate tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com