Light-weight high-intensity concrete and preparing method of light-weight high-intensity concrete

A technology of high-strength concrete and concrete, which is applied in the field of materials science, can solve the problems of high specific gravity and low strength of concrete, achieve low cost, simple production process, and improve the effect of particle gradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

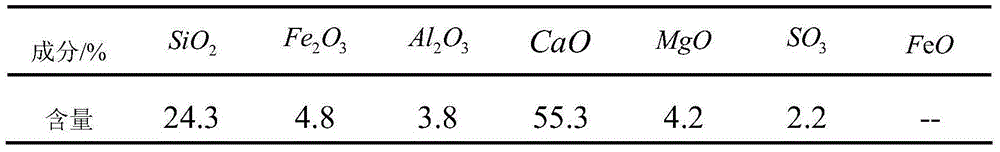

Method used

Image

Examples

Embodiment 1

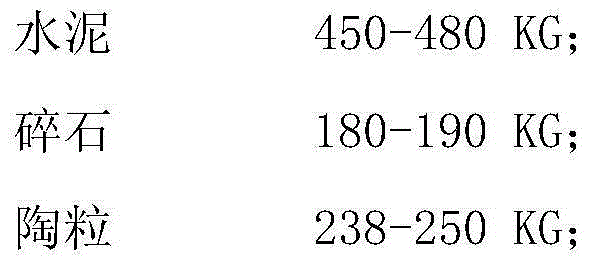

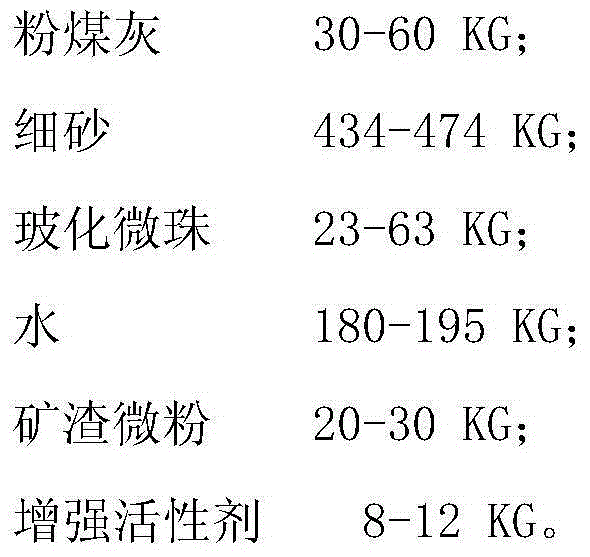

[0032] Weigh 470kg of cement, 189kg of gravel, 248kg of ceramsite, 50kg of fly ash, 464kg of fine sand, 33kg of vitrified microbeads, 187kg of water, 20kg of slag powder, and 10kg of calcium aluminate per cubic meter of concrete according to the specified ratio. The above-mentioned materials are put into the mixer, and after being fully stirred and mixed evenly, the lightweight high-strength concrete can be obtained by molding and curing.

Embodiment 2

[0034] Weigh 450kg of cement, 180kg of crushed stone, 257kg of ceramsite, 50kg of fly ash, 464kg of fine sand, 53kg of vitrified microbeads, 187kg of water, 25kg of slag powder, and 10kg of calcium oxide per cubic meter of concrete. Put it into the mixer, and after fully stirring and mixing evenly, it can be molded and cured to obtain lightweight high-strength concrete.

Embodiment 3

[0036] Weigh 480kg of cement, 199kg of gravel, 238kg of ceramsite, 50kg of fly ash, 464kg of fine sand, 23kg of vitrified microbeads, 185kg of water, 30kg of slag powder, and 12kg of sodium silicate per cubic meter of concrete according to the specified ratio. The above-mentioned materials are put into the mixer, and after being fully stirred and mixed evenly, the lightweight high-strength concrete can be obtained by molding and curing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com