Preparation method of carbonized steel slag lightweight aggregate and concrete containing carbonized steel slag lightweight aggregate

A technology of lightweight aggregate and carbonized steel, which is applied in the field of concrete containing carbonized steel slag lightweight aggregate, and the field of preparation of carbonized steel slag lightweight aggregate, which can solve the problem of long maintenance time of uncarbonized artificial aggregate, failure to achieve low-carbon environmental protection, and large Cement content and other issues to achieve the effect of enhancing internal curing ability, reducing the risk of cracking, and increasing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a method for preparing carbonized steel slag lightweight aggregate, which comprises the following steps:

[0028] Step 1. Weighing 40-60 parts by mass of steel slag powder, 30-50 parts by mass of vitrified microspheres and 10-30 parts by mass of quicklime are put into a tray and mixed to form a uniform mixed powder;

[0029] Step 2: Spray water droplets evenly on the surface of the mixed powder according to a certain water-cement ratio, and shake the oscillating tray continuously. The powder and water are mixed to form small balls, and the particle size is continuously increased to obtain steel slag with a particle size range of 5-20mm. lightweight aggregate;

[0030] Step 3. Place the steel slag lightweight aggregate in a curing room with a temperature of 20±1°C and a relative humidity of 55±5% for 48 hours;

[0031] Step 4. Put the cured steel slag light aggregate into the temperature of 20±1℃, relative humidity of 70±5%, CO 2 The carbonized s...

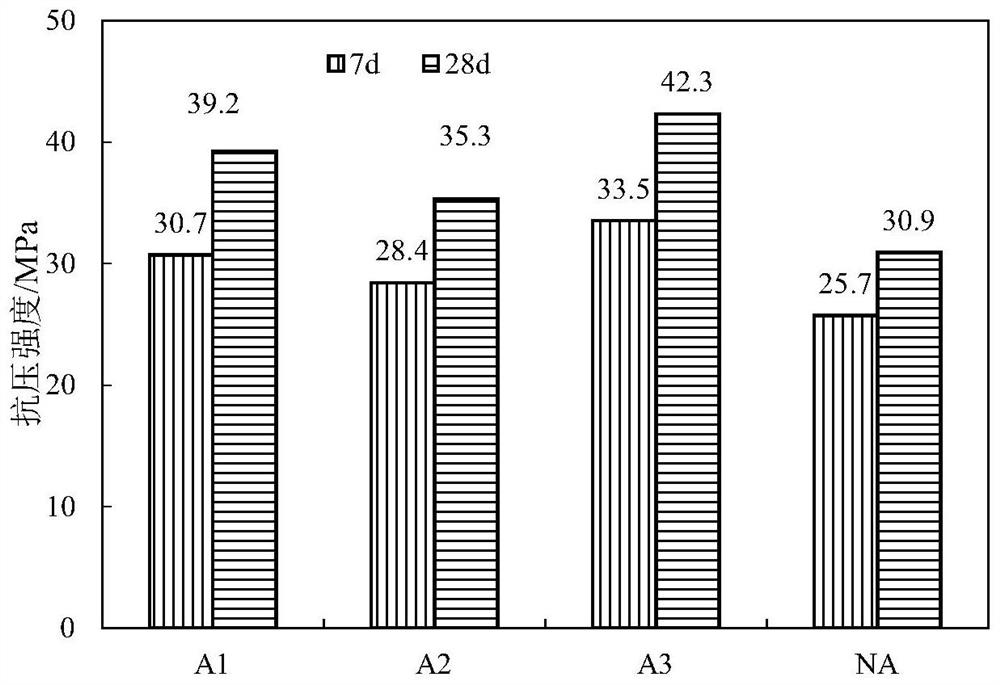

Embodiment 1

[0035] The present embodiment provides a method for preparing carbonized steel slag lightweight aggregate, said method comprising the following steps: weighing 40 parts by mass of steel slag powder, 40 parts by mass of vitrified microspheres and 20 parts by mass of quicklime by 0.30% of water ash After mixing into balls, place the obtained steel slag light aggregate in a curing room with a temperature of 20±1°C and a relative humidity of 55±5% for 48 hours. Then put the cured lightweight aggregate at a temperature of 20±1°C, a relative humidity of 70±5%, and CO 2 Carbonize in a carbonization box with a concentration of 80% for 24 hours to obtain carbonized steel slag light aggregate, which is denoted as A1.

Embodiment 2

[0037]The present embodiment provides a method for preparing carbonized steel slag lightweight aggregate, said method comprising the following steps: weighing 50 parts by mass of steel slag powder, 40 parts by mass of vitrified microspheres and 10 parts by mass of quicklime with 0.30 of water ash After mixing into balls, place the obtained steel slag light aggregate in a curing room with a temperature of 20±1°C and a relative humidity of 55±5% for 48 hours. Then put the cured lightweight aggregate at a temperature of 20±1°C, a relative humidity of 70±5%, and CO 2 Carbonize in a carbonization box with a concentration of 80% for 24 hours to obtain carbonized steel slag light aggregate, which is denoted as A2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com