Method for preparing tile grout

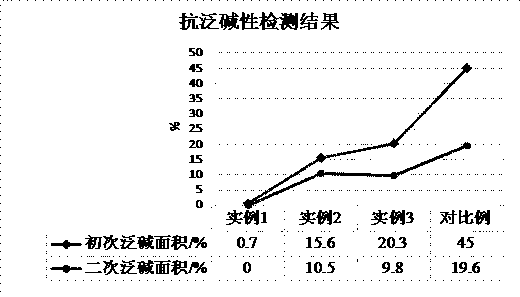

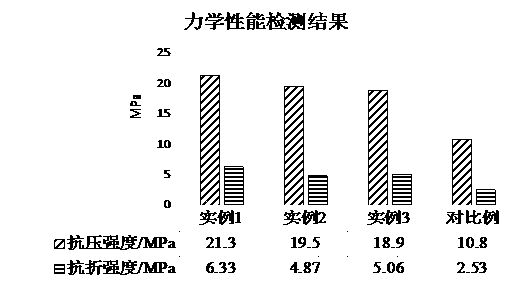

A technology for caulking and ceramic tiles, applied in the field of building materials, can solve the problems of easy efflorescence, poor mechanical properties of tile caulking agents, etc., and achieve the effects of enhanced mechanical properties, reduced efflorescence, and improved density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025]Mix chitosan and acetic acid solution with a mass fraction of 12% in a beaker at a mass ratio of 1:50, move the beaker into a digital speed measuring constant temperature magnetic stirrer, at a temperature of 36°C and a speed of 280r / min, After stirring and mixing for 40 minutes, add polyvinyl alcohol with 4 times the mass of chitosan to the beaker, stir and dissolve for 3 hours at a temperature of 85 ° C and a rotation speed of 300 r / min, and then add 0.6 mass of chitosan to the beaker. double the amount of glutaraldehyde, at a temperature of 60°C and a rotational speed of 320r / min, stir and react for 2 hours to obtain a mixed treatment solution, transfer the mixed treatment solution into a vacuum drying oven, and vacuum dry at a temperature of 50°C 6h to obtain chitosan-polyvinyl alcohol hydrogel; mix chitosan-polyvinyl alcohol hydrogel with saturated sodium carbonate solution at a mass ratio of 1:15, soak for 4 days at room temperature, and filter to obtain Pretreatme...

example 2

[0027] Mix protein and phosphate buffer solution with pH 7.4 in the flask at a mass ratio of 1:15, and add protease 0.06 times the protein mass to the flask, and then move the flask into a digital display speed measuring constant temperature magnetic stirrer at a temperature of 38°C , under the condition of rotating speed of 360r / min, constant temperature stirring and reaction for 40min, the degraded protein mixture was obtained; the natural zeolite was pulverized in a pulverizer, and passed through a 160 mesh sieve to obtain a pulverized zeolite, and the pulverized zeolite was obtained under the condition of a temperature of 280°C, Heat preservation treatment for 70 minutes to obtain pretreated zeolite. Mix the pretreated zeolite and degraded protein mixture at a mass ratio of 1:25. Stir and mix for 120 minutes at a rotation speed of 280 r / min at room temperature, then filter to obtain modified zeolite; Graphite and oxidant are mixed in a beaker at a mass ratio of 1:8, and the...

example 3

[0029] Mix chitosan and acetic acid solution with a mass fraction of 12% in a beaker at a mass ratio of 1:50, move the beaker into a digital speed measuring constant temperature magnetic stirrer, at a temperature of 36°C and a speed of 280r / min, After stirring and mixing for 40 minutes, add polyvinyl alcohol with 4 times the mass of chitosan to the beaker, stir and dissolve for 3 hours at a temperature of 85 ° C and a rotation speed of 300 r / min, and then add 0.6 mass of chitosan to the beaker. double the amount of glutaraldehyde, at a temperature of 60°C and a rotational speed of 320r / min, stir and react for 2 hours to obtain a mixed treatment solution, transfer the mixed treatment solution into a vacuum drying oven, and vacuum dry at a temperature of 50°C 6h to obtain chitosan-polyvinyl alcohol hydrogel; mix chitosan-polyvinyl alcohol hydrogel with saturated sodium carbonate solution at a mass ratio of 1:15, soak for 4 days at room temperature, and filter to obtain Pretreatm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com