Cement concrete for wet connection seam of system sequentially comprising simply-supported bridge and continuous bridge, and preparation method thereof

A simply supported and then continuous cement concrete technology, applied in bridge cement concrete materials, cement concrete and its preparation, to achieve high toughness, self-leveling and low modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

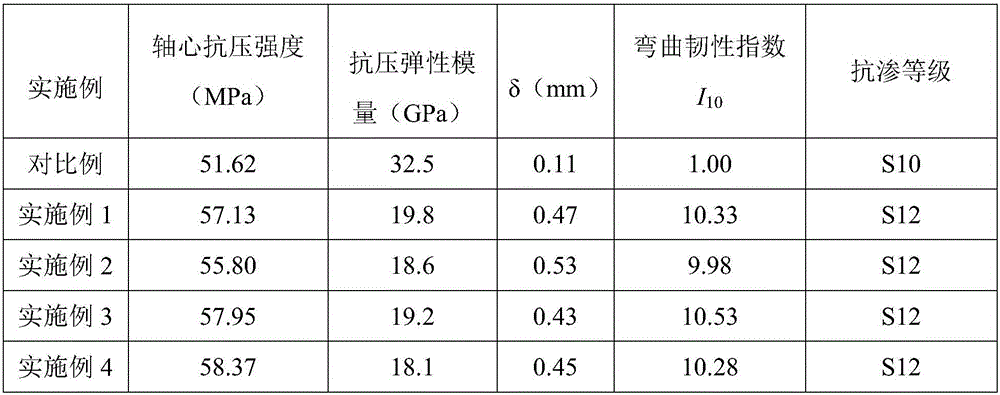

Examples

Embodiment 1

[0045] Example 1: Cement Concrete for Wet Joints of Simply Supported Bridges Then Continuous

[0046] The cement concrete used for the wet joints of simply supported and then continuous bridges provided in this example is composed of the following raw materials in terms of weight percentage: 35% cement; 27% river sand; 16% water; 1% water reducing agent; Rice husk ash 7%; apatite 5%; sericite 0.8%; sepiolite 2.2%; sodium polyacrylate superabsorbent resin 0.8%; talcum powder 2%; nano calcium carbonate 2%; hybrid fiber 1.2%. The sum of the weight percentages of raw materials is 100%.

[0047] Wherein the weight ratio of polyethylene fiber and polyester fiber in the hybrid fiber is 65:35.

[0048] The above-mentioned preparation method of the cement concrete used for the wet joints of simply supported bridges followed by continuous bridges is carried out according to the following steps:

[0049] Step 1. Take the above-mentioned raw materials respectively according to the mass ...

Embodiment 2

[0054] Example 2: Cement Concrete for Wet Joints of Simply Supported Bridges Then Continuous

[0055] The difference between this embodiment and the above-mentioned embodiment 1 lies in the ratio of each raw material. The cement concrete is composed of the following raw materials in terms of weight percentage: 25% cement; 25% river sand; 19% water; 1% water reducer; 10% rice husk ash; 6% apatite; %; sepiolite 3.2%; sodium polyacrylate superabsorbent resin 0.5%; talcum powder 3%; nano calcium carbonate 4%; hybrid fiber 2%. The sum of the weight percentages of raw materials is 100%.

[0056] Wherein the weight ratio of polyethylene fiber and polyester fiber in the hybrid fiber is 60:40.

Embodiment 3

[0057] Example 3: Cement Concrete for Wet Joints of Simply Supported Bridges Then Continuous

[0058] The difference between this embodiment and the above-mentioned embodiment 1 lies in the ratio of each raw material. The cement concrete is composed of the following raw materials in terms of weight percentage: 40% cement; 25% river sand; 17% water; 0.8% water reducer; 5% rice husk ash; 4% apatite; %; sepiolite 1.8%; sodium polyacrylate superabsorbent resin 1.5%; talcum powder 2.5%; nano calcium carbonate 1%; hybrid fiber 0.8%. The sum of the weight percentages of raw materials is 100%.

[0059] Wherein the weight ratio of polyethylene fiber and polyester fiber in the hybrid fiber is 70:30.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com