Steel fiber high-strength concrete and preparation method thereof

A steel fiber, high-strength technology, applied in the field of steel fiber high-strength concrete and its preparation, can solve the problems of poor bonding performance, easy pulling out of steel fiber, affecting the compressive performance of steel fiber concrete, etc. Reduce the risk of thermal cracking, good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

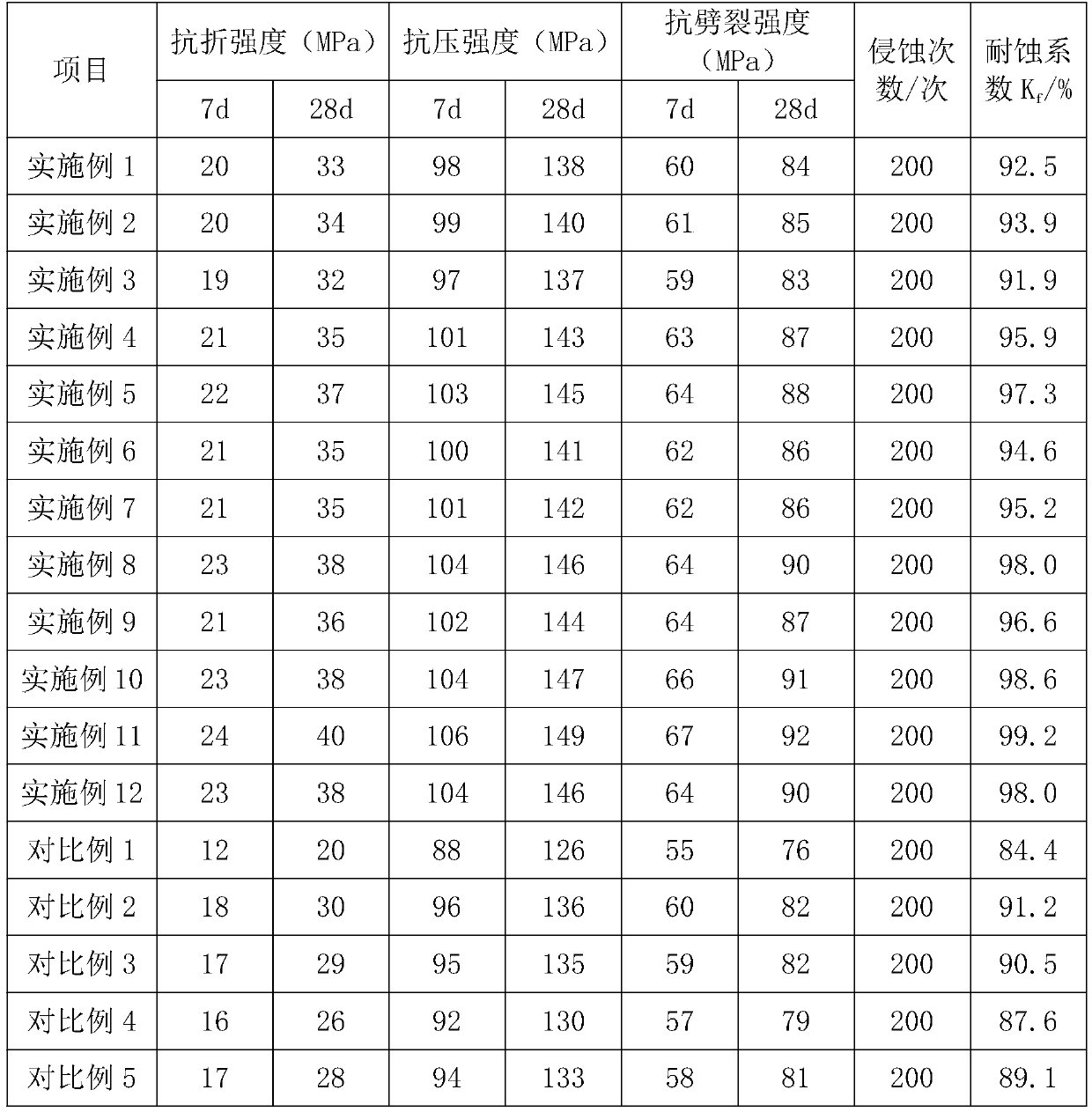

Examples

Embodiment 1

[0059] A preparation method for steel fiber high-strength concrete, comprising the following steps:

[0060] (1) Add 5g of admixture to 60g of water, stir to make it evenly mixed, and obtain a mixed solution;

[0061] (2) 10g organic fibers, 6g modified steel fibers are mixed with half of the mixed solution obtained in step (1), and stirred evenly to obtain a mixture;

[0062] (3) 400g of cement, 80g of fly ash, 85g of mineral powder, and 10g of silica fume are added to the mixture, and stirred evenly to obtain the primary mixture;

[0063] (4) Add 700g of fine aggregate and the remaining mixed solution in step (1) to the initial mixture obtained in step (3), and stir evenly to obtain the base material;

[0064] (5) Add 800g of coarse aggregate and 65g of water into the base material of step (4), and stir to obtain steel fiber high-strength concrete; wherein,

[0065] Admixture comprises 1.2g polycarboxylic acid, 1.5g organosilicon oil and 2.3g rosin soap, namely the weight ...

Embodiment 2

[0071] A preparation method for steel fiber high-strength concrete, comprising the following steps:

[0072] (1) Add 6g of admixture to 74g of water, stir to make it evenly mixed, and obtain a mixed solution;

[0073] (2) 14g organic fibers, 10.5g modified steel fibers are mixed with half of the mixed solution obtained in step (1), and stirred evenly to obtain a mixture;

[0074] (3) 440g cement, 850g fly ash, 95g mineral powder, 12.5g silica fume are added in the mixture, and stir evenly, get primary mixture;

[0075] (4) Add 730g of fine aggregate and the remaining mixed solution in step (1) to the initial mixture obtained in step (3), and stir evenly to obtain the base material;

[0076] (5) Add 850g of coarse aggregate and 74g of water into the base material of step (4), and stir to obtain steel fiber high-strength concrete; wherein,

[0077] The admixture comprises 1.6g polycarboxylic acid, 1.6g organosilicon oil and 2.8g rosin soap, that is, the weight ratio of polycar...

Embodiment 3

[0083] A preparation method for steel fiber high-strength concrete, comprising the following steps:

[0084] (1) Add 7g of admixture to 85g of water, stir to make it evenly mixed, and obtain a mixed solution;

[0085] (2) 18g organic fibers, 15g modified steel fibers are mixed with half of the mixed solution obtained in step (1), and stirred evenly to obtain a mixture;

[0086] (3) 480g cement, 105g fly ash, 105g mineral powder, 15g silica fume are added in the mixture, and stir evenly, get primary mixture;

[0087] (4) Add 760g of fine aggregate and the remaining mixed solution in step (1) to the initial mixture obtained in step (3), and stir evenly to obtain the base material;

[0088] (5) 900g of coarse aggregate and 85g of water are added in the base material of step (4), stirred evenly to obtain steel fiber high-strength concrete; wherein,

[0089] The admixture comprises 2.0g polycarboxylic acid, 1.7g organosilicon oil and 3.3g rosin soap, that is, the weight ratio of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com