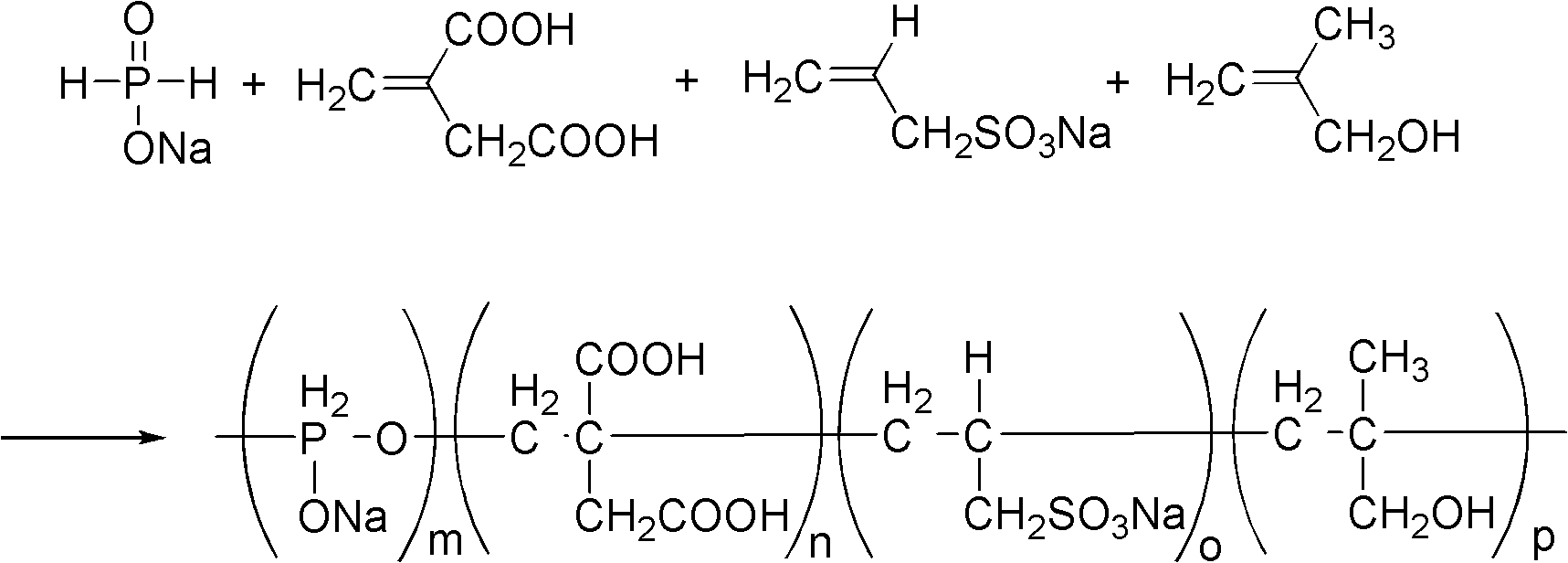

Propenol itaconic acid sulfonate multipolymer scale inhibiting agent and preparation method thereof

A technology of propylene alcohol itaconate sulfonate and multiple copolymers, which is applied in the fields of scale removal and water softening, chemical instruments and methods, water/sludge/sewage treatment, etc. Solve the problems of large amount of additives, etc., and achieve the effects of simple production process, good dispersion, formation of scale layer and adhesion inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In a four-neck flask equipped with a mechanical stirrer, a constant pressure dropping funnel, and a thermometer, add 130 g of itaconic acid, 72 g of isopropanol, and 400 g of distilled water, and heat to 60 ° C to completely dissolve the itaconic acid; Dissolve 18g of sodium in 50g of distilled water, add it quickly after itaconic acid dissolves; then heat up to 90°C; dissolve 18g of sodium propylene sulfonate in 55g of distilled water, add 100g of distilled water and 15g of sodium persulfate to prepare the initiator; Add 27g of sodium hypophosphite and 15g of propylene alcohol to 100g of distilled water to prepare a reducing agent; after the itaconic acid solution is heated to 70°C, quickly add 30ml of initiator and 10ml of reducing agent, and dissolve the initiator and reducing agent within 2 hours Evenly drop into the beaker, maintain the reaction temperature at 90 ° C, after the monomer and initiator are added dropwise, continue to keep warm (insulate for 20 minutes)...

Embodiment 2

[0035]In a four-necked flask equipped with a mechanical stirrer, a constant pressure dropping funnel, and a thermometer, add 150 g of itaconic acid, 72 g of isopropanol, and 400 g of distilled water, and heat to 60 ° C to completely dissolve the itaconic acid; Dissolve 8g of sodium in 50g of distilled water, add it quickly after itaconic acid dissolves; then heat up to 90°C; dissolve 8g of sodium propylene sulfonate in 55g of distilled water, add 100g of distilled water and then 8g of sodium persulfate to prepare the initiator; Add 8g of sodium hypophosphite and 8g of allyl alcohol to 100g of distilled water to prepare a reducing agent; after the itaconic acid solution is heated to 70°C, add 30ml of initiator and 10ml of reducing agent quickly, and dissolve the initiator and reducing agent within 2 hours Evenly drop into the beaker, maintain the reaction temperature at 90 ° C, after the monomer and initiator are added dropwise, continue to keep warm (insulate for 20 minutes) an...

Embodiment 3

[0039] In a four-necked flask equipped with a mechanical stirrer, a constant pressure dropping funnel, and a thermometer, add 120 g of itaconic acid, 72 g of isopropanol, and 400 g of distilled water, and heat to 60 ° C to completely dissolve the itaconic acid; Sodium 30g is dissolved in 80g distilled water, after itaconic acid dissolves, add quickly; then heat up to 90°C; dissolve 30g sodium propylene sulfonate in 100g distilled water, add 100g distilled water and then add 18g sodium persulfate to prepare the initiator; Add 36g of sodium hypophosphite and 24g of propylene alcohol to 100g of distilled water to prepare a reducing agent; after the itaconic acid solution is heated to 70°C, quickly add 30ml of initiator and 10ml of reducing agent, and dissolve the initiator and reducing agent within 2 hours Evenly drop into the beaker, maintain the reaction temperature at 90 ° C, after the monomer and initiator are added dropwise, continue to keep warm (insulate for 20 minutes) and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com