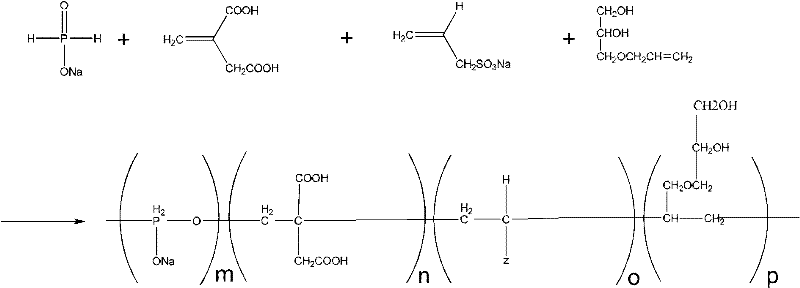

Ether-based itaconic acid sulfonate type multi-copolymer scale inhibitor and method for preparing same

A technology based on itaconic acid sulfonate and multi-component copolymers, which is applied in the fields of scale removal and water softening, chemical instruments and methods, water/sludge/sewage treatment, etc., and can solve the problems of poor scale inhibition effect and inorganic addition amount Large, single and other problems, to achieve good dispersion, simple production process, the formation of scale and the effect of adhesion inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In a four-neck flask equipped with a mechanical stirrer, a constant pressure dropping funnel, and a thermometer, add 130 g of itaconic acid, 72 g of isopropanol, and 400 g of distilled water, and heat to 60 ° C to completely dissolve the itaconic acid; Dissolve 18g of sodium in 50g of distilled water, add it quickly after itaconic acid dissolves; then heat up to 90°C; dissolve 18g of sodium propylene sulfonate in 55g of distilled water, add 100g of distilled water and 15g of sodium persulfate to prepare the initiator; Add 27g of sodium hypophosphite and 15g of α-allyl glyceryl ether to 100g of distilled water to prepare a reducing agent; Evenly drop into the beaker within 2 hours, maintain the reaction temperature at 90 ° C, after the monomer and initiator are added dropwise, continue to keep warm (insulated for 20 minutes) and react for a period of time (hereinafter referred to as "reaction time"). Stop heating, stirring, distill, recover isopropanol, control the tempe...

Embodiment 2

[0036]In a four-necked flask equipped with a mechanical stirrer, a constant pressure dropping funnel, and a thermometer, add 150 g of itaconic acid, 72 g of isopropanol, and 400 g of distilled water, and heat to 60 ° C to completely dissolve the itaconic acid; Dissolve 8g of sodium in 50g of distilled water, add it quickly after itaconic acid dissolves; then heat up to 90°C; dissolve 8g of sodium propylene sulfonate in 55g of distilled water, add 100g of distilled water and then 8g of sodium persulfate to prepare the initiator; Add 8g of sodium hypophosphite and 8g of α-allyl glyceryl ether to 100g of distilled water to prepare a reducing agent; Evenly drop into the beaker within 2 hours, maintain the reaction temperature at 90 ° C, after the monomer and initiator are added dropwise, continue to keep warm (insulated for 20 minutes) and react for a period of time (hereinafter referred to as "reaction time"). Stop heating, stirring, distill, recover isopropanol, control the temp...

Embodiment 3

[0040] In a four-necked flask equipped with a mechanical stirrer, a constant pressure dropping funnel, and a thermometer, add 120 g of itaconic acid, 72 g of isopropanol, and 400 g of distilled water, and heat to 60 ° C to completely dissolve the itaconic acid; Sodium 30g is dissolved in 80g distilled water, after itaconic acid dissolves, add quickly; then heat up to 90°C; dissolve 30g sodium propylene sulfonate in 100g distilled water, add 100g distilled water and then add 18g sodium persulfate to prepare the initiator; Add 36g of sodium hypophosphite and 24g of α-allyl glyceryl ether to 100g of distilled water to prepare a reducing agent; Evenly drop into the beaker within 2 hours, maintain the reaction temperature at 90 ° C, after the monomer and initiator are added dropwise, continue to keep warm (insulated for 20 minutes) and react for a period of time (hereinafter referred to as "reaction time"). Stop heating, stirring, distill, recover isopropanol, control the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com